Heart-shaped ring for pre-twisted strain clamp and manufacturing process of heart-shaped ring

A tension-resistant clamp and manufacturing process technology, applied in hot-dip plating process, metal material coating process, adjusting/maintaining mechanical tension, etc., can solve problems such as unstable quality and casting defects, and achieve stable quality and casting defects small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

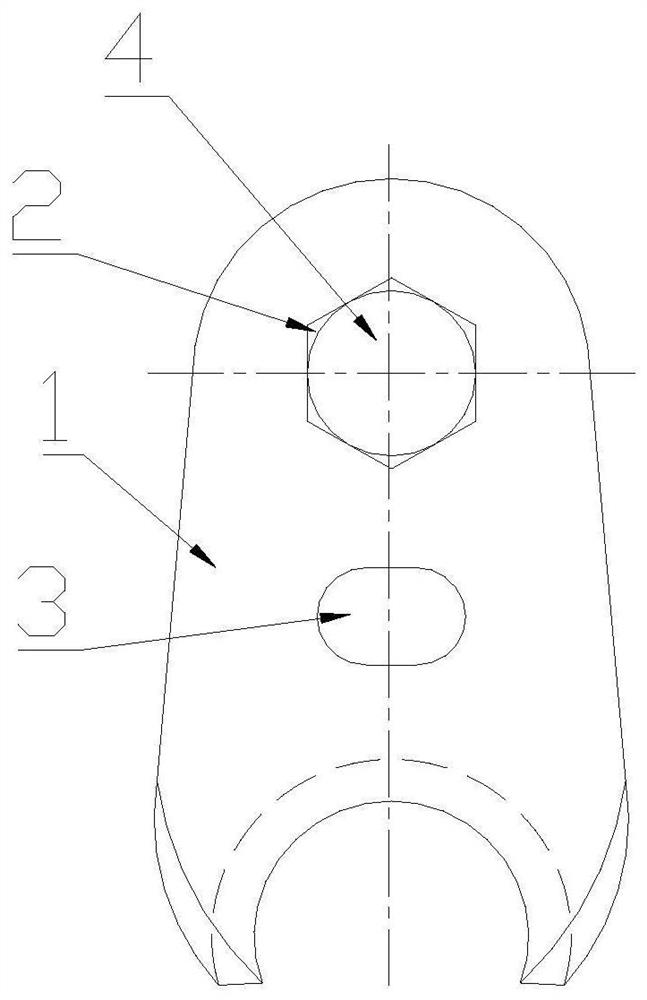

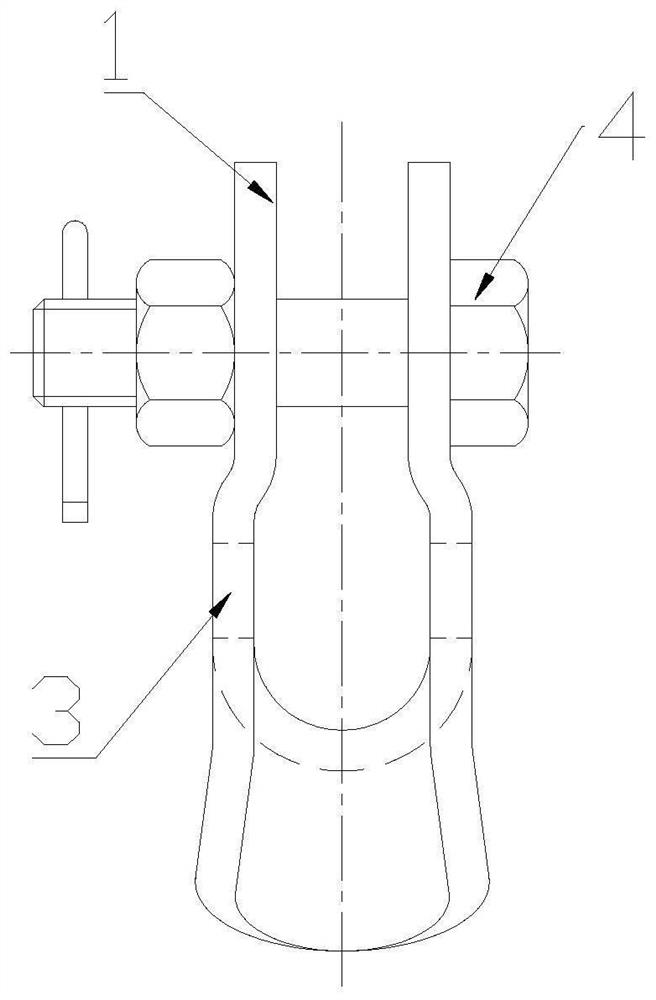

[0023] As attached in the manual Figure 1 to Figure 2 A heart-shaped ring for a pre-twisted tension clamp shown in the figure includes a heart-shaped ring body 1, the upper part of the heart-shaped ring body 1 is provided with a hardware bolt hole 2, and the middle part of the heart-shaped ring body 1 is provided with a through hole 3. Fitting bolts 4 are inserted in the fitting bolt holes 2 .

[0024] The hole diameter of the hardware bolt hole is 28mm.

[0025] The radius of the arc at the lower part of the heart-shaped ring body is 25.4mm.

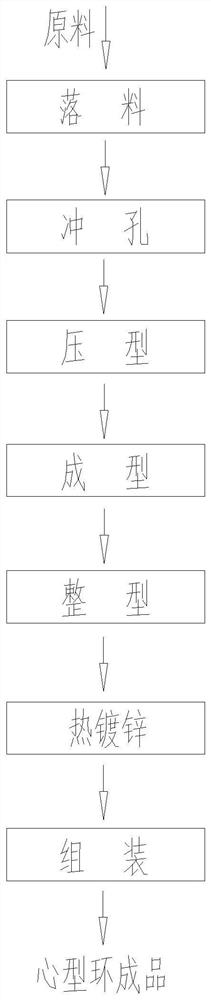

[0026] as attached image 3 As shown, a manufacturing process of a pre-twisted tension clamp with a heart-shaped ring includes the following steps:

[0027] Step 1: Blanking the raw material through the blanking mold;

[0028] Step 2: The blanked module is punched through the punching die;

[0029] Step 3: After punching, the module is pressed;

[0030] Step 4: The molded module is formed by the molding module, and the blank is h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap