Environmental protection monitoring and energy saving optimization oriented cloth bag dust collector

A bag dust collector, environmental protection technology, applied in the direction of transportation and packaging, chemical instruments and methods, separation of dispersed particles, etc., can solve the problems affecting the normal operation of the production line, trouble, poor filtering effect, etc., to achieve low pressure, slow flow rate, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

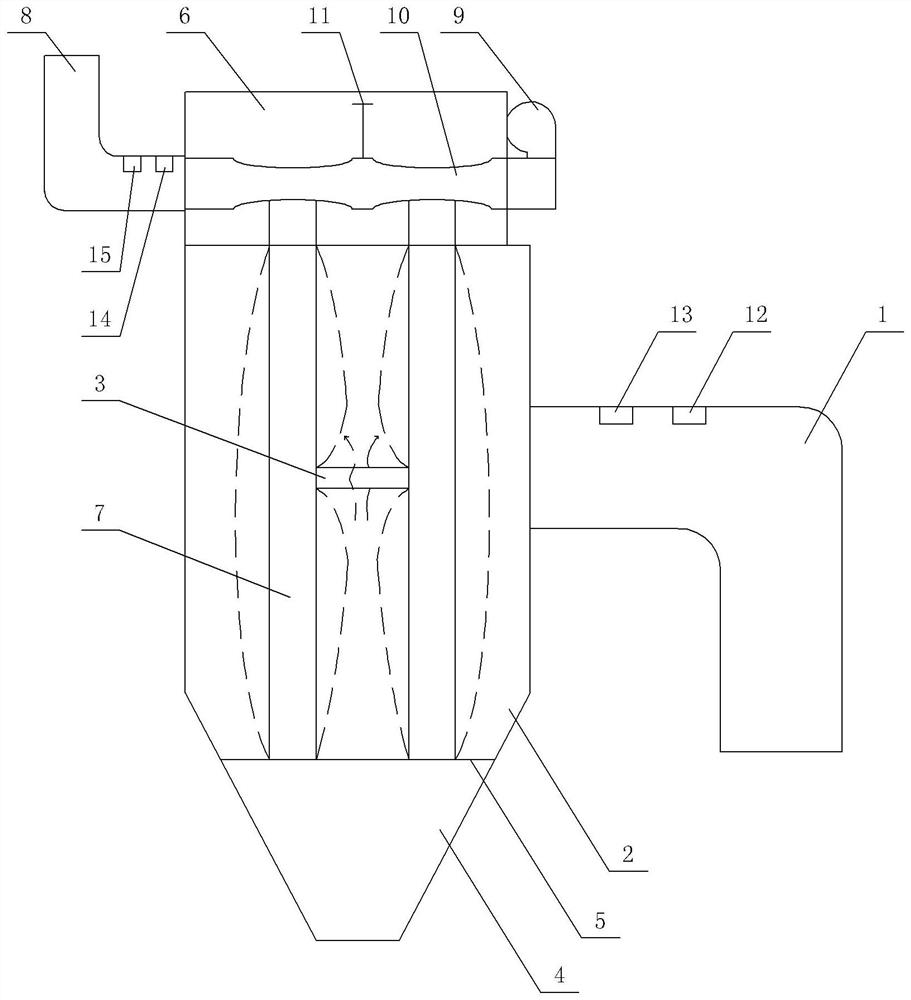

[0020] Embodiment one is basically as attached figure 1 Shown: as figure 1 The shown is a bag filter for environmental protection monitoring and energy saving optimization, including a dust collection pipe 1, a dust collection box 2 and a connecting pipe 3, the dust collection pipe 1 is welded to the dust collection box 2, and the lower end of the dust collection box 2 is integrated An ash hopper 4 is welded, and a wire filter 5 is welded in the ash hopper 4. The upper end of the dust collection box 2 is a clean air chamber 6; two filter bags 7 are arranged in the dust collection box 2, that is, the lower end of the filter bag 7 is connected with the filter bag. The net 5 is stitched and connected, the upper end of the filter bag 7 is stitched and connected with the top of the dust collection box 2; the inner wall of the dust collection box 2 is welded with a support rod, the middle part of the connecting pipe 3 is welded with the support rod, and the filter bags 7 are connect...

Embodiment 2

[0026] On the basis of Embodiment 1, it also includes an inlet dust concentration detector alarm 12, an outlet dust concentration detector alarm 13, an inlet pressure transmitter 14, an outlet pressure transmitter 15 and an electric control box, and the inlet dust concentration detection The instrument alarm 12 and the inlet pressure transmitter 14 are installed on the inner wall of the dust collection pipe 1 by bolts, and the outlet dust concentration detector alarm 13 and the outlet pressure transmitter 15 are installed on the inner wall of the air outlet pipe 8 by bolts; Among them, the dust concentration detector alarm can choose the GCG1000 dust concentration detector alarm provided by Jinan Youda Electronics Co., Ltd., or the pipeline dust concentration detector RJDT series provided by Ruijun Technology; the pressure transmitter can choose the model BST6800 -GP pressure transmitter, or select the pressure transmitter model E+H PMC71; the electric control box is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com