A motor coil insulation powder coating machine

A coil insulation and powder coating technology, which is applied in coating, electrostatic spraying device, liquid spraying equipment, etc., can solve the problems of large motor coils that cannot be realized and affect human health, and can overcome automatic preheating and static electricity. The effect of automatic curing of insulating powder, novel structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

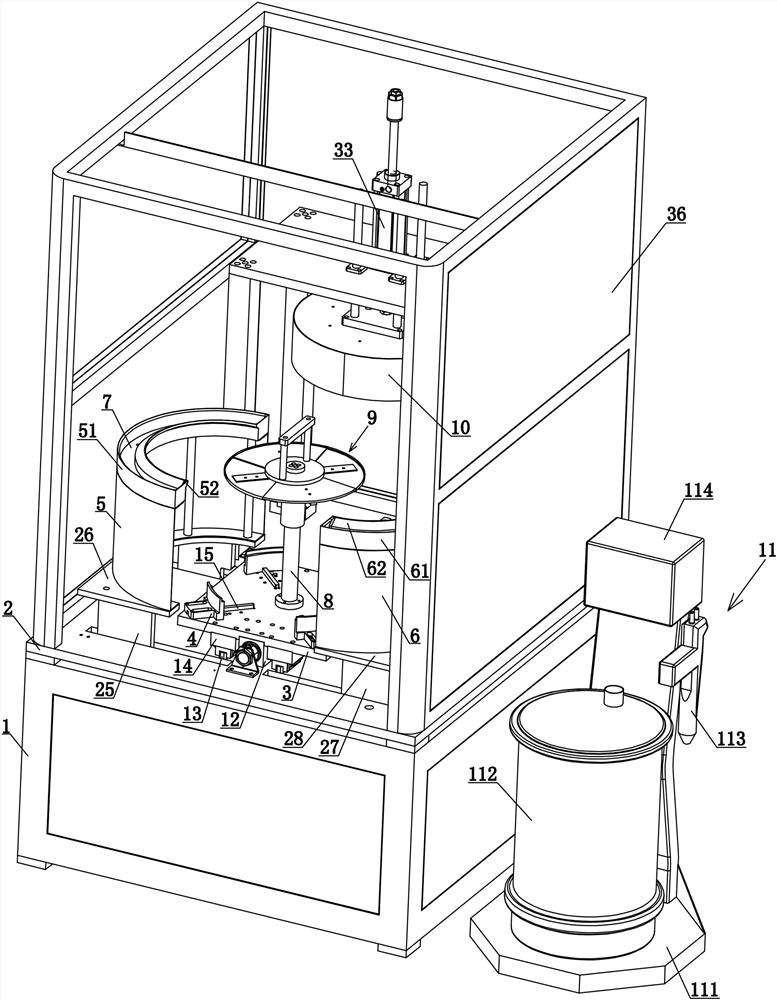

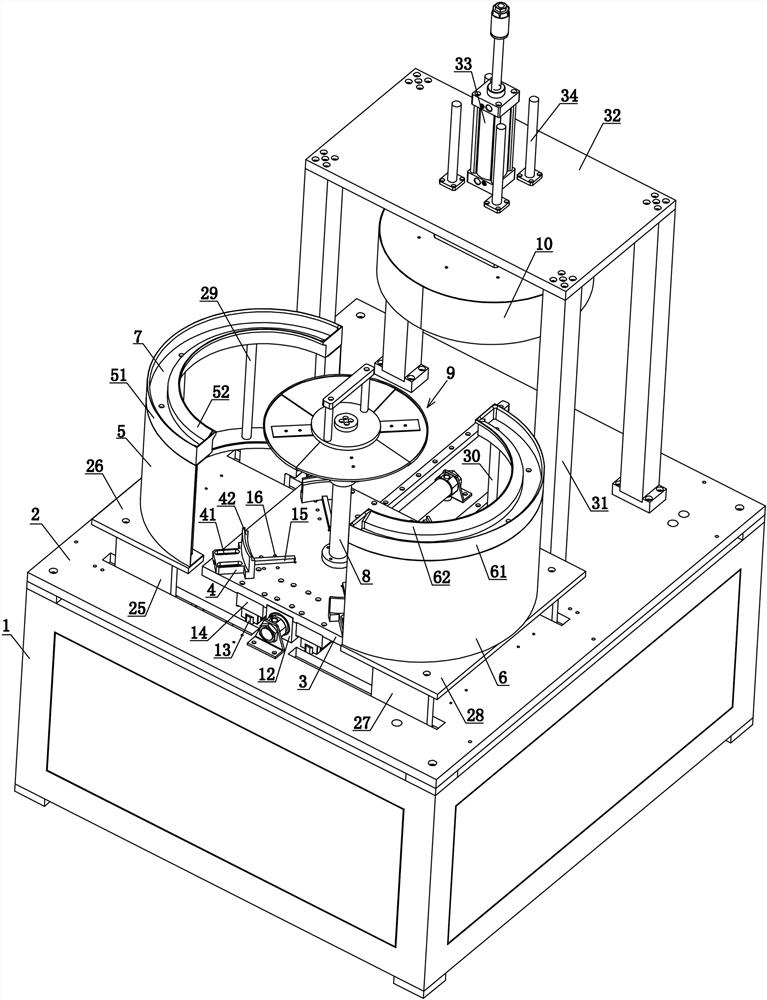

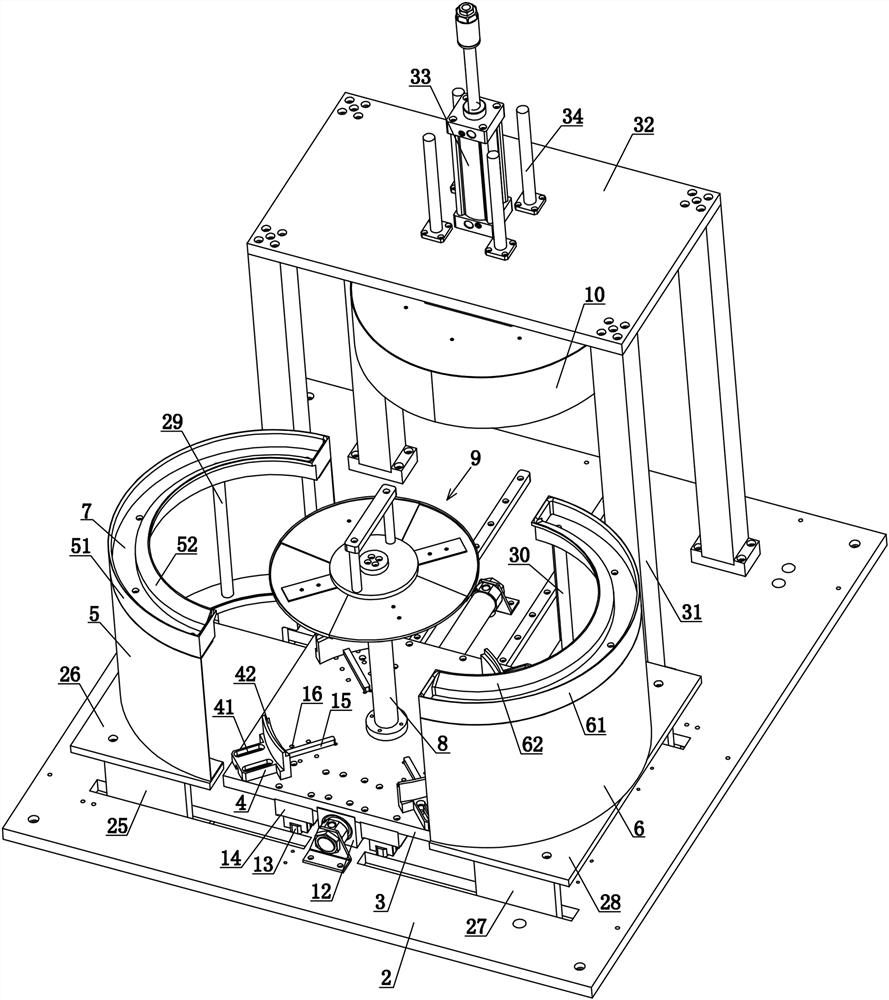

[0023] refer to figure 1 and figure 2 . A motor coil insulation powder coating machine, comprising a frame 1, the top of the frame 1 is provided with a top plate 2, the top plate 2 is provided with a worktable 3 that can move forward and backward, and the top surface of the workbench 3 is provided with There are positioning devices for fixing the motor coil and the position is adjustable. The top of the top plate 2 is provided with a left circular arc housing 5 and a right circular arc housing 6 that can move left and right, and the left circular arc housing 5 and right circular arc housing 6 are located above the workbench 3 , the top surfaces of the left circular arc housing 5 and the right circular arc housing 6 are respectively provided with a left circular arc cover plate 51 and a right circular arc cover plate 61 which can cover the top surface of the iron core outside the winding coil. The top surfaces of the arc cover plate 51 and the right arc cover plate 61 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com