Replica grating gluing and curing integrated system

A grating-replicating, integrated technology, applied in the direction of diffraction gratings, devices for coating liquid on the surface, connecting components, etc., can solve the problems of low detection and control accuracy, poor product consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

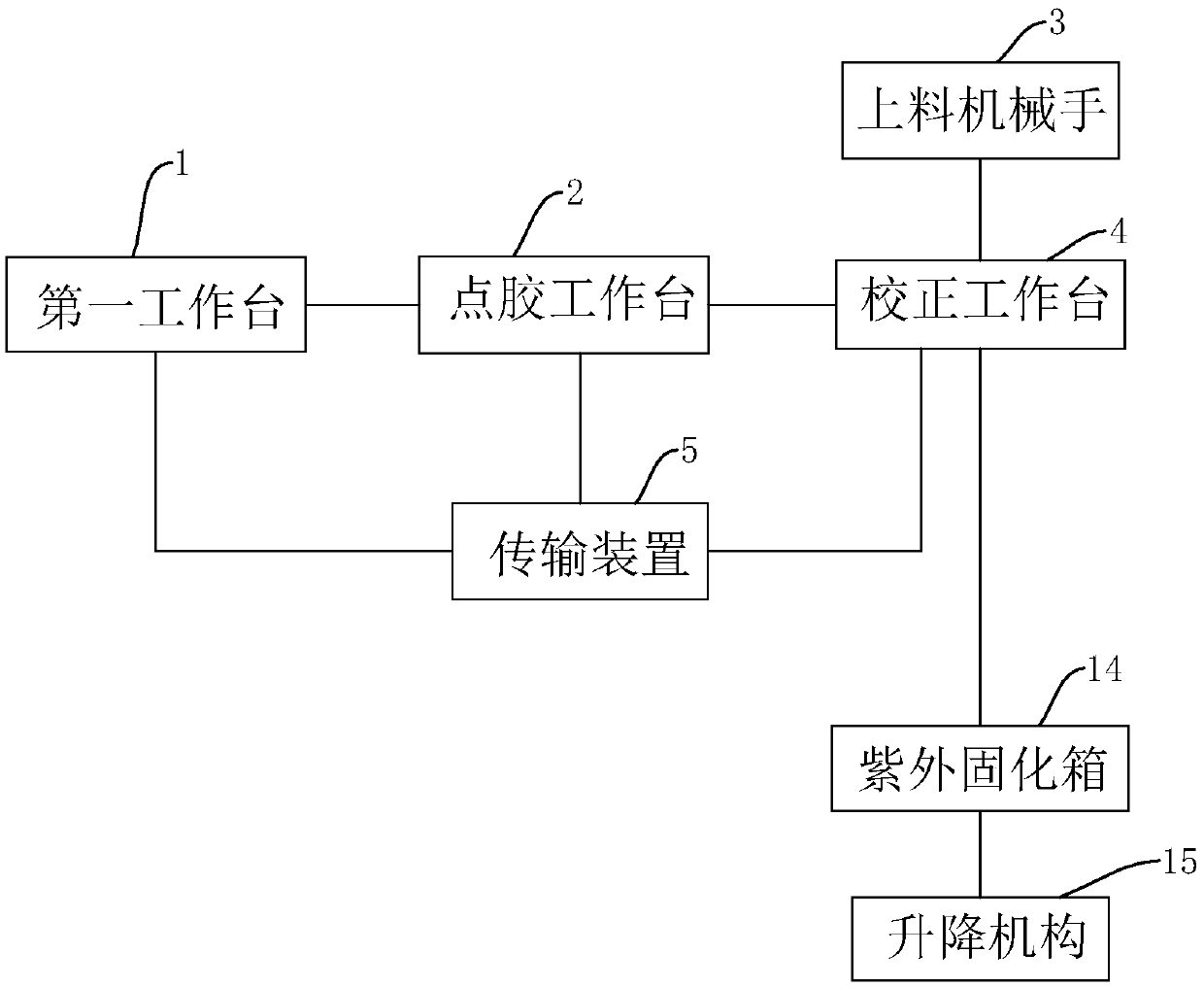

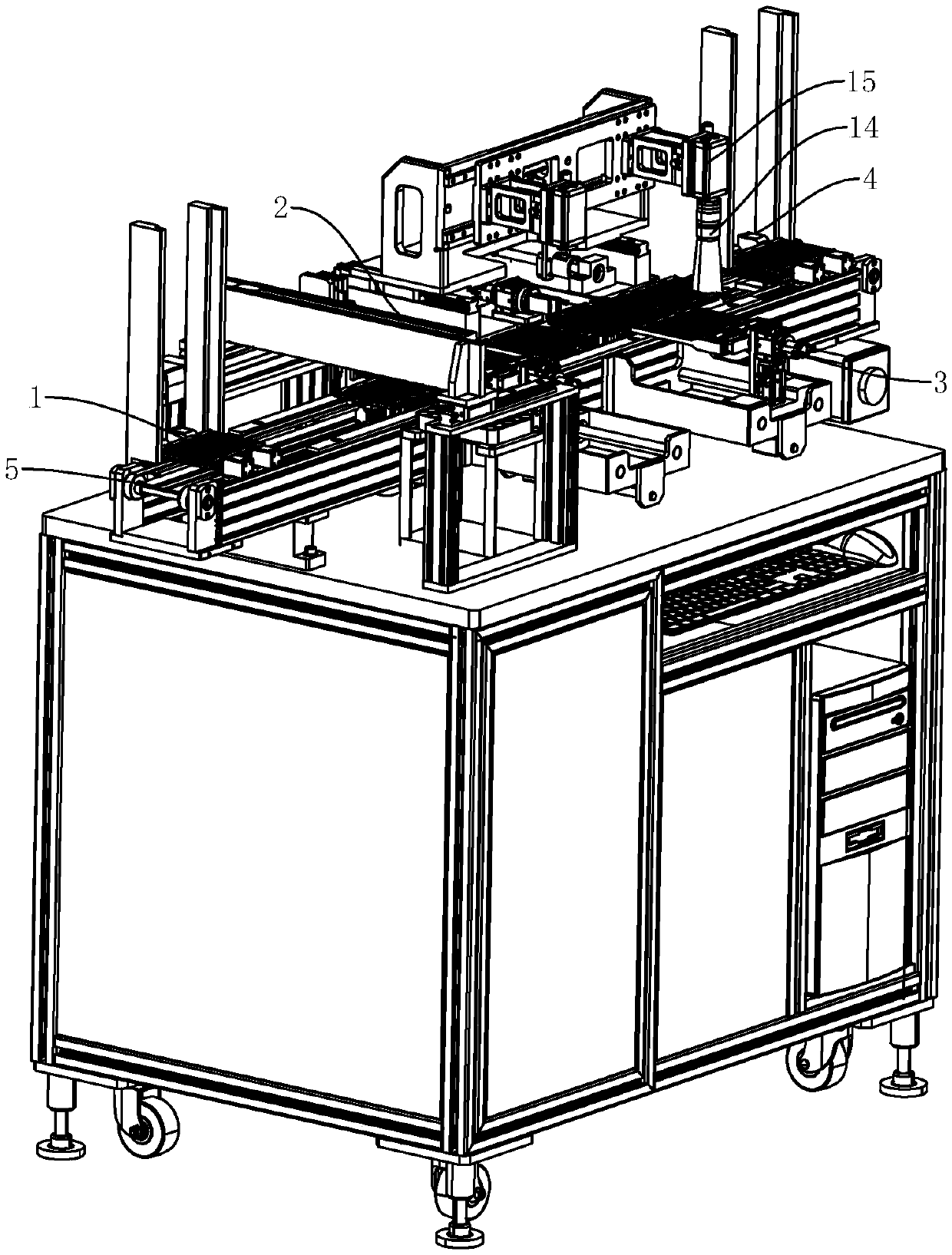

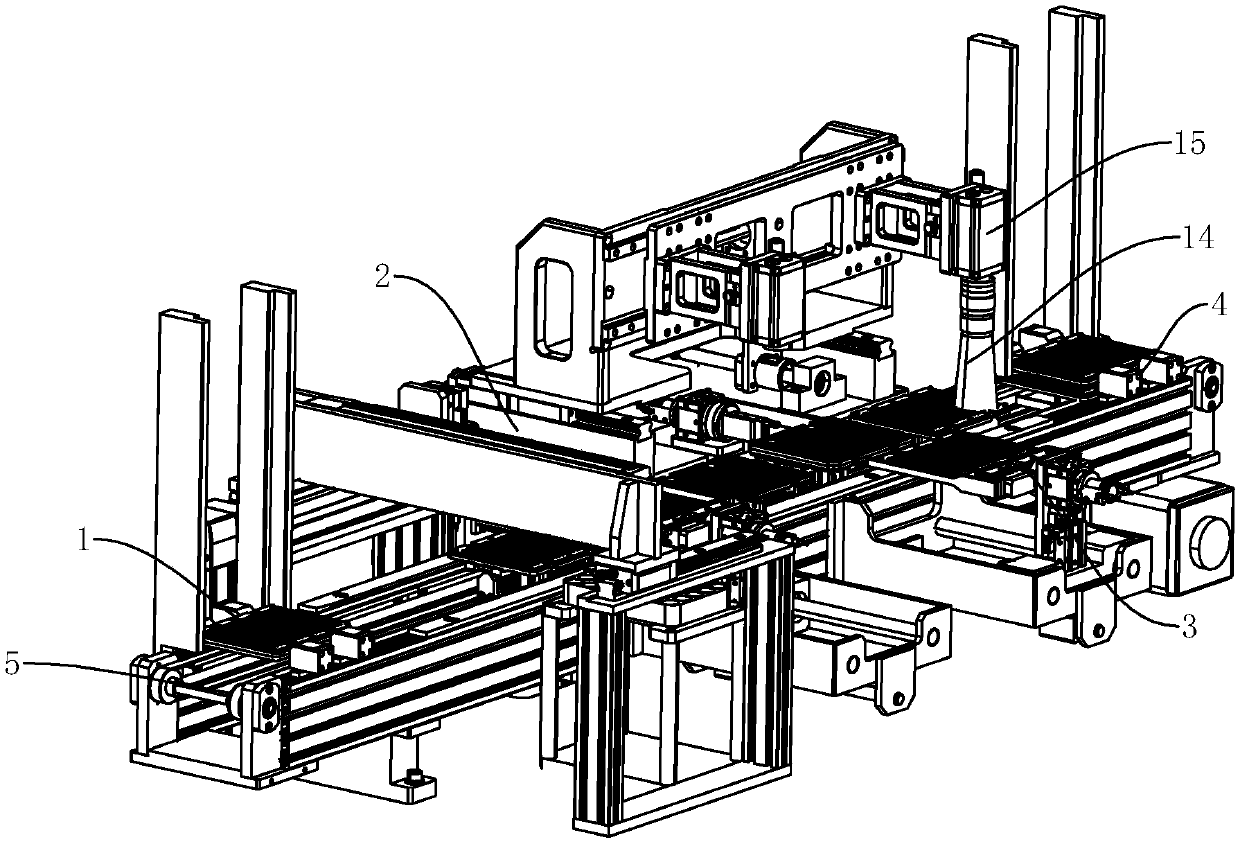

[0040] An integrated system for gluing and curing replicated gratings, including a first workbench 1, a dispensing workbench 2 for dispensing the gold-plated master grating b, and a glue-dispensing workbench 2 for directly covering the replicated base blank a on the master grating b The feeding manipulator 3, the correction table 4 for position correction of the copy base a, and the transmission device 5 for transmitting the master grating b also include a UV curing box 14, and a lifting mechanism 15 is arranged on the UV curing box 14, For fastening, ultraviolet curing treatment is performed on the replication base a at the calibration workbench 4 . The ultraviolet curing box 14 is a structure of a cover, and an ultraviolet lamp is arranged in the cover. The replication base a is directly cured through the ultraviolet curing box 14, and the lifting mechanism 15 can be used for automatic control, and the work efficiency is high.

[0041] Through the transmission device 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com