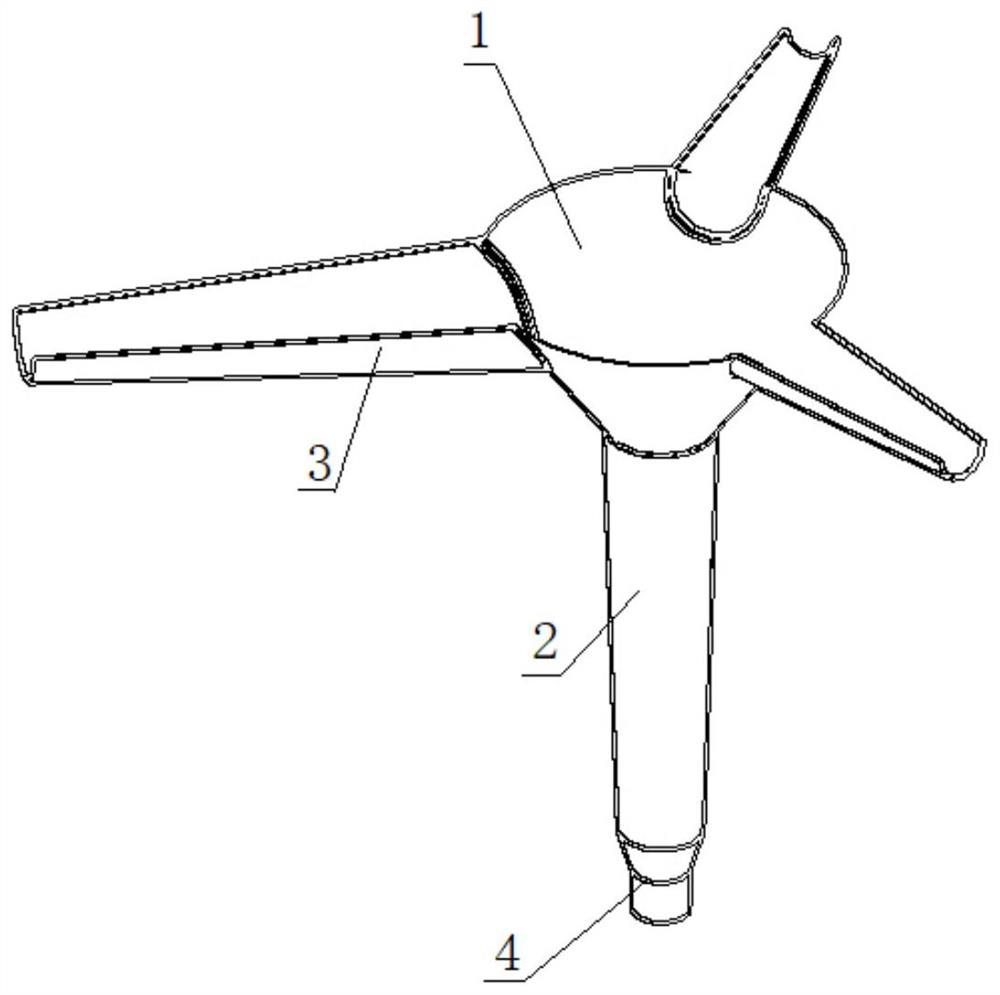

Positive pressure nozzle for steel transfer

A molten steel and pressure technology, applied in the field of metallurgy, can solve problems such as slag protrusion, lower molten steel quality, and unusable residual steel, and achieve the effects of reducing processing costs, improving molten steel quality, and improving steelmaking production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

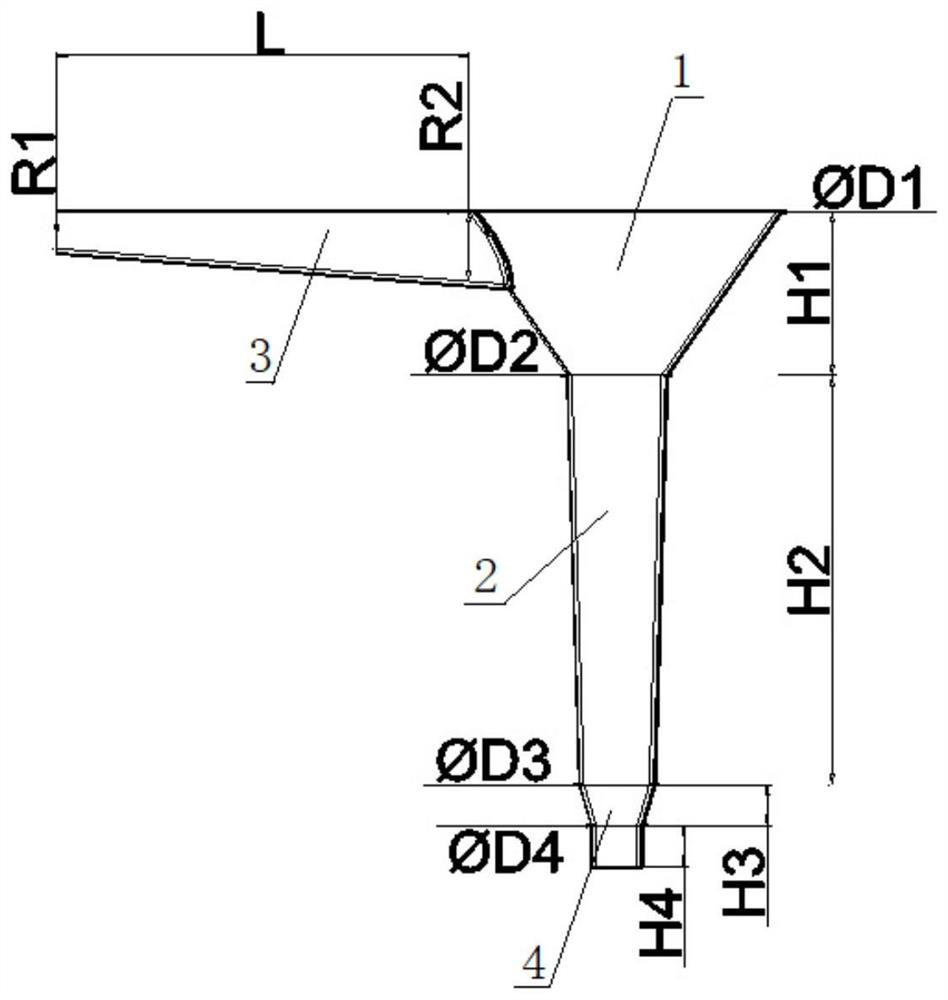

Embodiment 1

[0061] Embodiment 1: A positive pressure strong nozzle, R1=20mm, R2=30mm, L=150mm, three slope-shaped diversion grooves 3, evenly distributed around the molten steel convergence area 1; D1=120mm, D2=60mm, H1= 60mm, D3=40mm, H2=250mm, D4=35mm, H3=20mm, H4=20mm, the exhaustion time is 23s, the critical height of the vortex is about 30mm, and the tapered transition section 2 is from top to bottom 1 / 4, 1 / Drill three small holes at the 2nd and 3 / 4th places. When the valve is opened, it can be seen that the water flows out from the small holes, and the water flow ranges in turn. It shows that the water flow produces a positive pressure, and the positive pressure at the lower part of the nozzle is greater;

Embodiment 2

[0062] Embodiment 2: A positive pressure strong nozzle, R1=20mm, R2=40mm, L=150mm, three slope diversion grooves 3, evenly distributed around the molten steel convergence area 1, D1=200mm, D2=70mm, H1= 80mm, D3=50mm, H2=350mm, D4=40mm, H3=20mm, H4=20mm, exhaustion time 21s, vortex critical height<40mm, vortex intensity is weak, stream is regular flow, weak impact on the next container, The sound is small, and the number of bubbles entering the water is large and small;

Embodiment 3

[0063] Embodiment 3: A positive pressure strong nozzle, R1=20mm, R2=40mm, L=150mm, three slope diversion grooves 3, evenly distributed around the molten steel convergence area 1, D1=240mm, D2=70mm, H1= 80mm, D3=50mm, H2=400mm, D4=40mm, H3=20mm, H4=150mm, exhaustion time 18s, vortex critical height<40mm, slightly larger than Example 2, vortex intensity is weak, stream is regular flow, The impact on the next container is weak, the sound is small, and the number of bubbles entering the water is large and small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com