Environment-friendly laser marking system with protection function

A technology of laser marking and protective functions, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of reducing the efficiency of workers loading and unloading, inconvenient use, inconvenient opening and use, etc., to improve the marking speed of the system , Improve the marking speed and optimize the operability of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

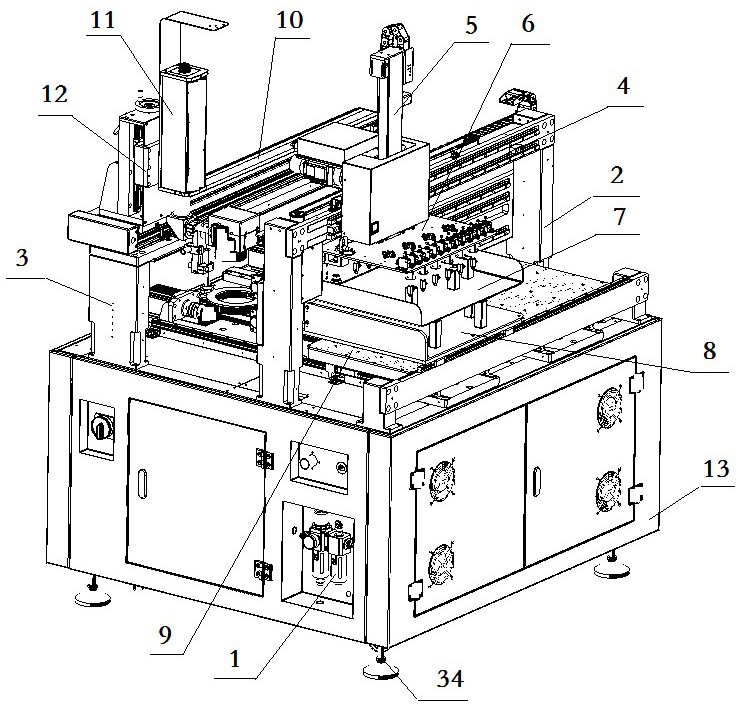

[0020] An environment-friendly laser marking system with protection function, which consists of: manual loading and unloading and automatic loading and unloading FPC marking equipment body 1 (the prior art), the manual loading and unloading and automatic loading and unloading FPC marking equipment body has a front Bracket 2 and rear bracket 3, the front bracket is connected to the reclaiming horizontal moving shaft 4, the reclaiming horizontal moving shaft is connected to the reclaiming vertical moving shaft 5, and the reclaiming vertical moving shaft is connected to the reclaiming sucker 6 , the suction cup for taking materials corresponds to the blanking station 7, the bottom of the blanking station is provided with a loading station 8, the bottom of the loading station is provided with a marking station 9, and the rear The support is connected to the laser automatic horizontal movement shaft 10, and the laser automatic horizontal movement shaft is connected to the laser 11 a...

Embodiment 2

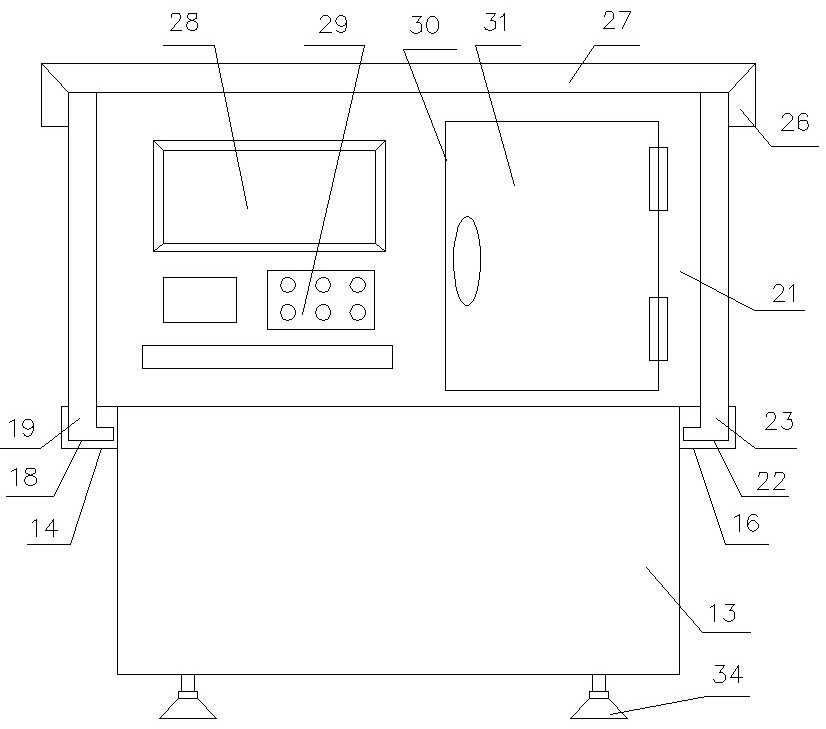

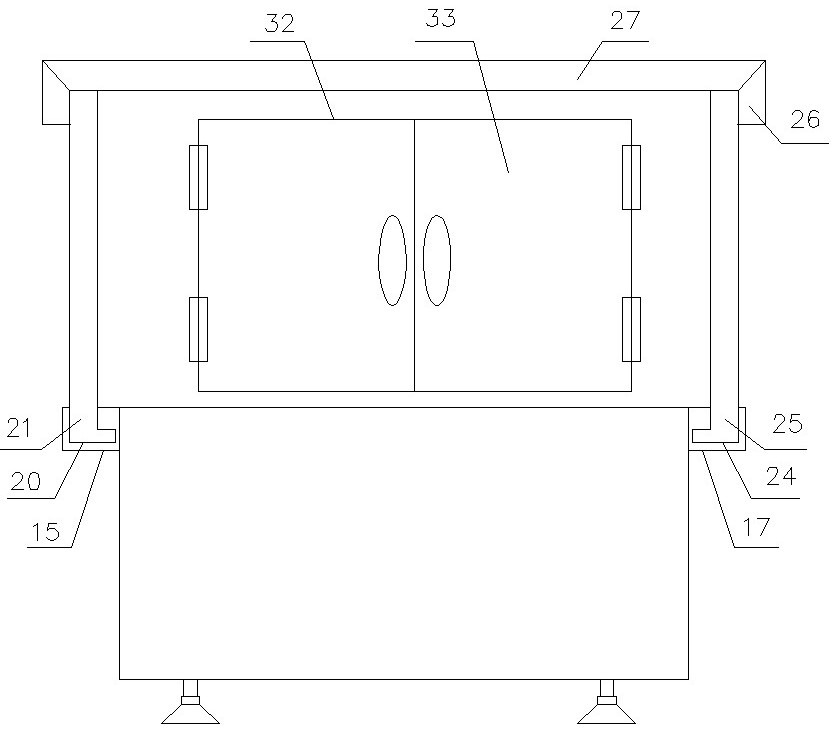

[0023] A kind of environment-friendly laser marking system with protection function described in embodiment 1, the described manual loading and unloading and automatic loading and unloading FPC marking equipment body has a lower box body 13, and the described lower box body has a top surface, the described The top surface of the top surface is fixed and vertically connected to the left supporting plate 14, the front supporting plate 15, the right supporting plate 16, and the rear supporting plate 17. The grooves are tightly matched and inserted into the left protective plate 19. After the left protective plate is assembled, it is firm and stable, and it is also convenient to assemble. Insert and connect the front protective plate 21 tightly, the front protective plate is firm and stable after assembly, and it is also convenient during assembly. Cooperate with inserting and connecting the right protective plate 23. After the right protective plate is assembled, it is firm and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com