Heat-dissipating laser marking system with angle adjusting function

A technology of laser marking and angle adjustment, which is applied to laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of reducing the efficiency of workers loading and unloading, inconvenient use, and inconvenient opening and use, so as to improve the marking speed of the system , Improve the marking speed and optimize the operability of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

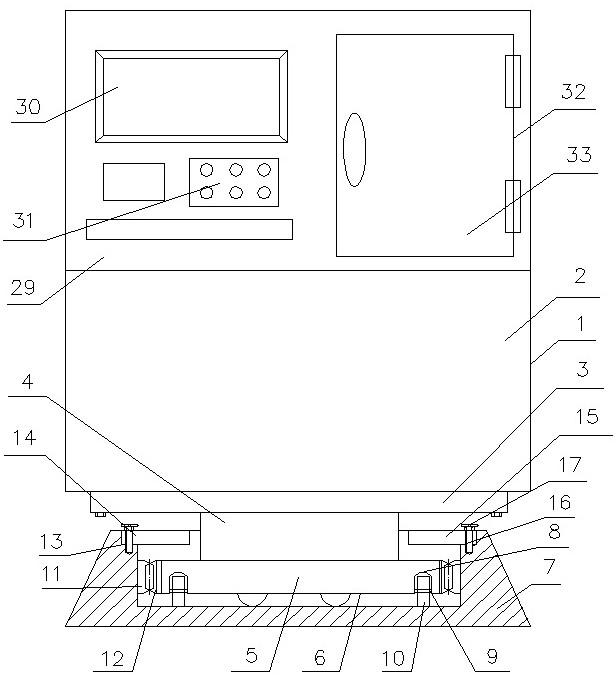

[0019] A heat-dissipating laser marking system with an angle adjustment function, which consists of: a manual loading and unloading and automatic loading and unloading FPC marking equipment body 1 (being the prior art), and the manual loading and unloading and automatic loading and unloading FPC marking equipment body has The lower box 2, the bottom of the lower box is connected to the bottom disc 3 and fixed by screws, the bottom disc is fixedly connected to the bottom pillar 4, and the bottom pillar is fixedly connected to the rotary disc 5, the The rotating disk is installed in the ring groove 6, and the rotating disk can rotate freely in the ring groove, which is convenient for manual loading and unloading and automatic loading and unloading. In the base 7, an inverted U-shaped annular groove 8 is opened on the bottom of the rotating disc, and the annular groove is connected with a group of shafts 9 around the circumference, and the shaft is connected with a round wheel 10 ...

Embodiment 2

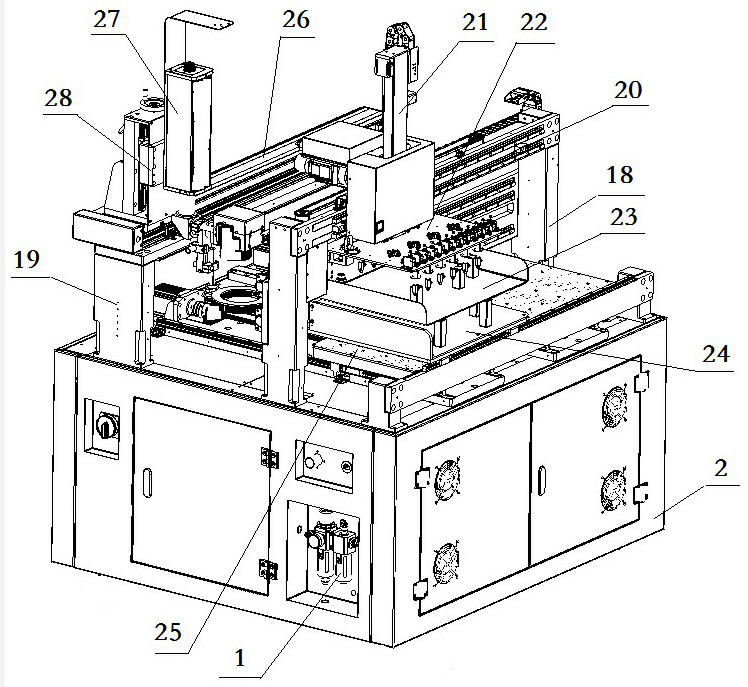

[0023] A heat-dissipating laser marking system with an angle adjustment function described in Embodiment 1, the FPC marking equipment body with manual loading and unloading and automatic loading and unloading has a front bracket 18 and a rear bracket 19, and the front bracket is connected to the feeding Horizontal moving shaft 20, the described horizontal moving shaft for retrieving is connected to the vertical moving shaft 21 for use, the vertical moving shaft for retrieving is connected to the retrieving suction cup 22, and the described suction cup for retrieving corresponds to the blanking station 23, so The bottom of the blanking station is provided with a loading station 24, and the bottom of the loading station is provided with a marking station 25. The rear support is connected to the laser automatic horizontal movement axis 26, and the automatic horizontal movement of the laser is The mobile axis connects the laser 27 and the laser manually adjusts the vertical axis 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com