Leachate back-spraying system

A technology of leachate and leachate, which is applied in the direction of polluted groundwater/leachate treatment, water/sludge/sewage treatment, filtration treatment, etc. Problems such as the inability of the spray system to run smoothly, to achieve a good spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the drawings.

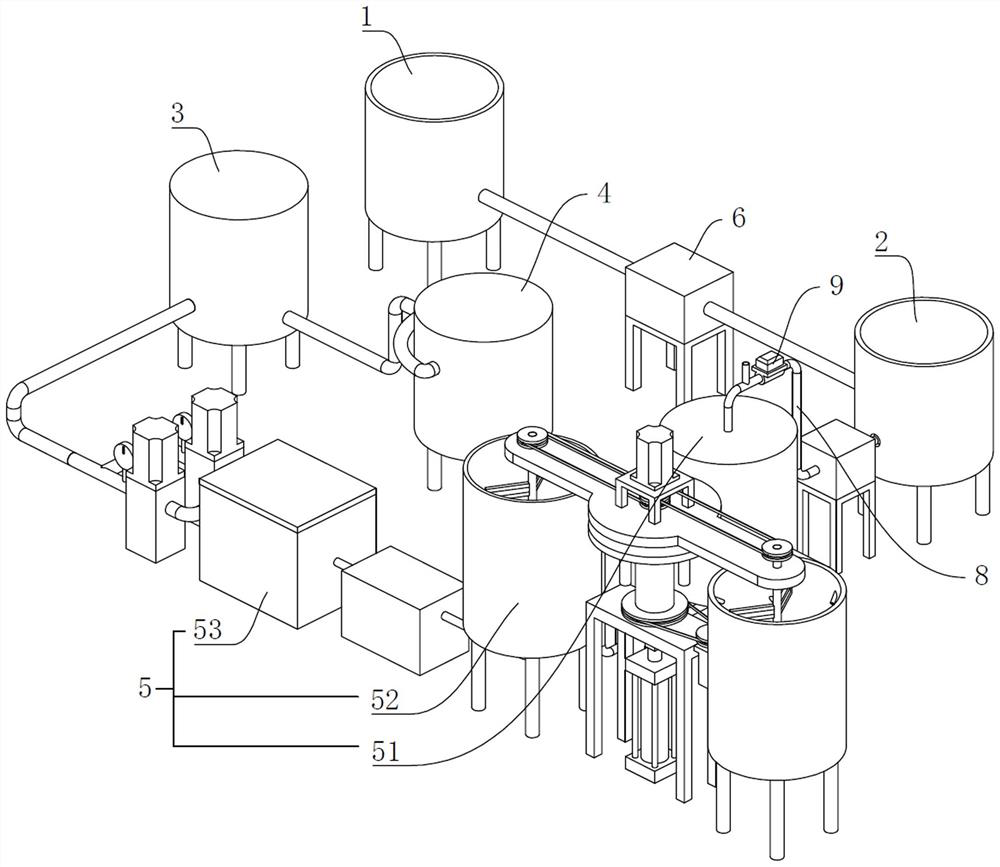

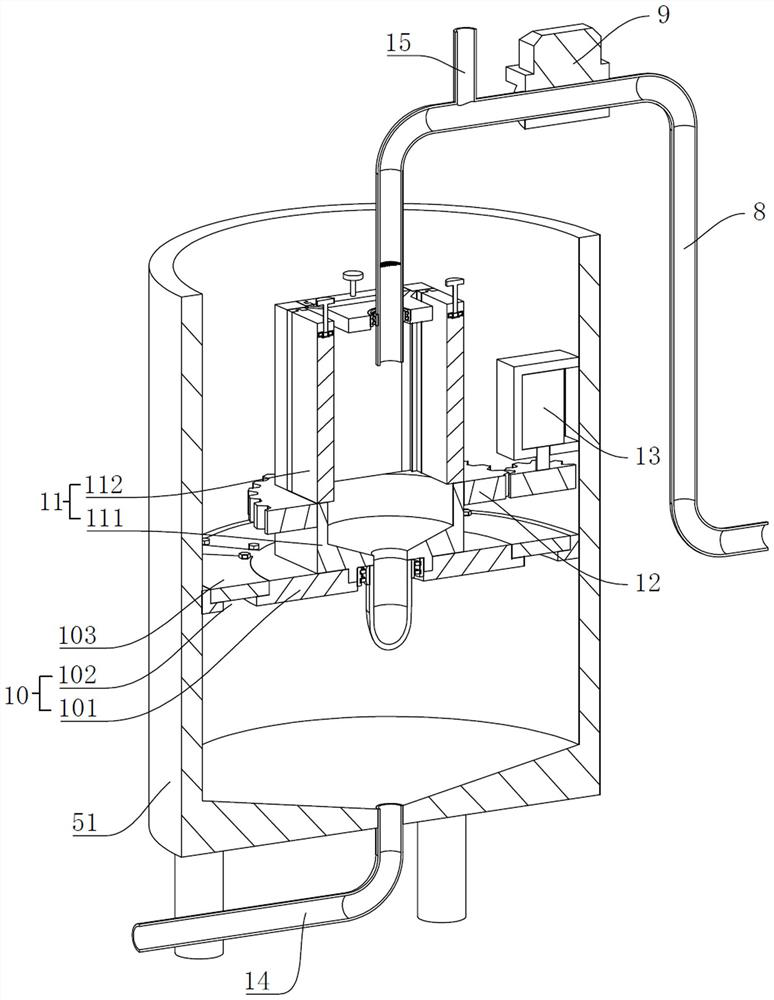

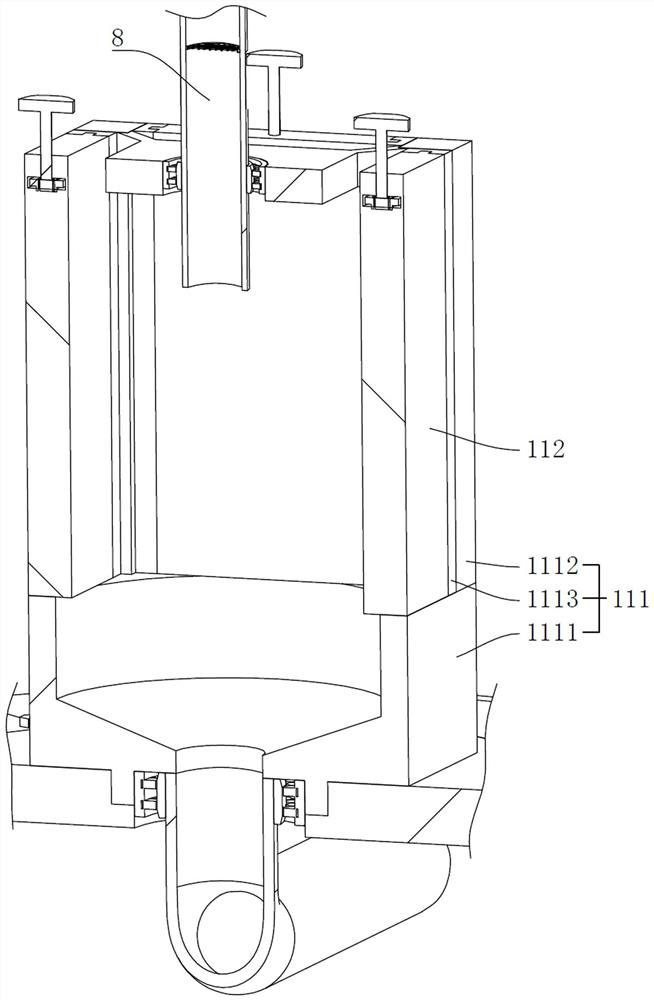

[0045] Reference figure 1 , Is a leachate back spray system disclosed in the present invention, including a leachate collection tank 2 connected to the garbage pool 1, the leachate collection tank 2 is connected with a leachate intermediate storage tank 3, and the leachate intermediate storage tank 3 is connected with The incinerator 4, the filter tank group 5 is set between the leachate collection tank 2 and the leachate intermediate storage tank 3, between the garbage tank 1 and the leachate collection tank 2, between the leachate collection tank 2 and the filter tank group 5, Between the filter tank group 5 and the percolate intermediate storage tank 3, and between the percolate intermediate storage tank 3 and the incinerator 4, a delivery pump group 6 is provided. The delivery pump group 6 can provide power for the flow and delivery of the percolate to ensure the percolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com