Soft soil roadbed geosynthetic material three-dimensional reinforcement treatment construction method

A technology of geosynthetic material and soft soil subgrade, applied in the direction of roads, roads, buildings, etc., can solve the problems of unsatisfactory reinforcement effect, high cost of composite pile method, and high mechanical equipment, so as to enhance the lateral restraint resistance and large-scale The anti-deformation ability, improve the construction speed and reduce the construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

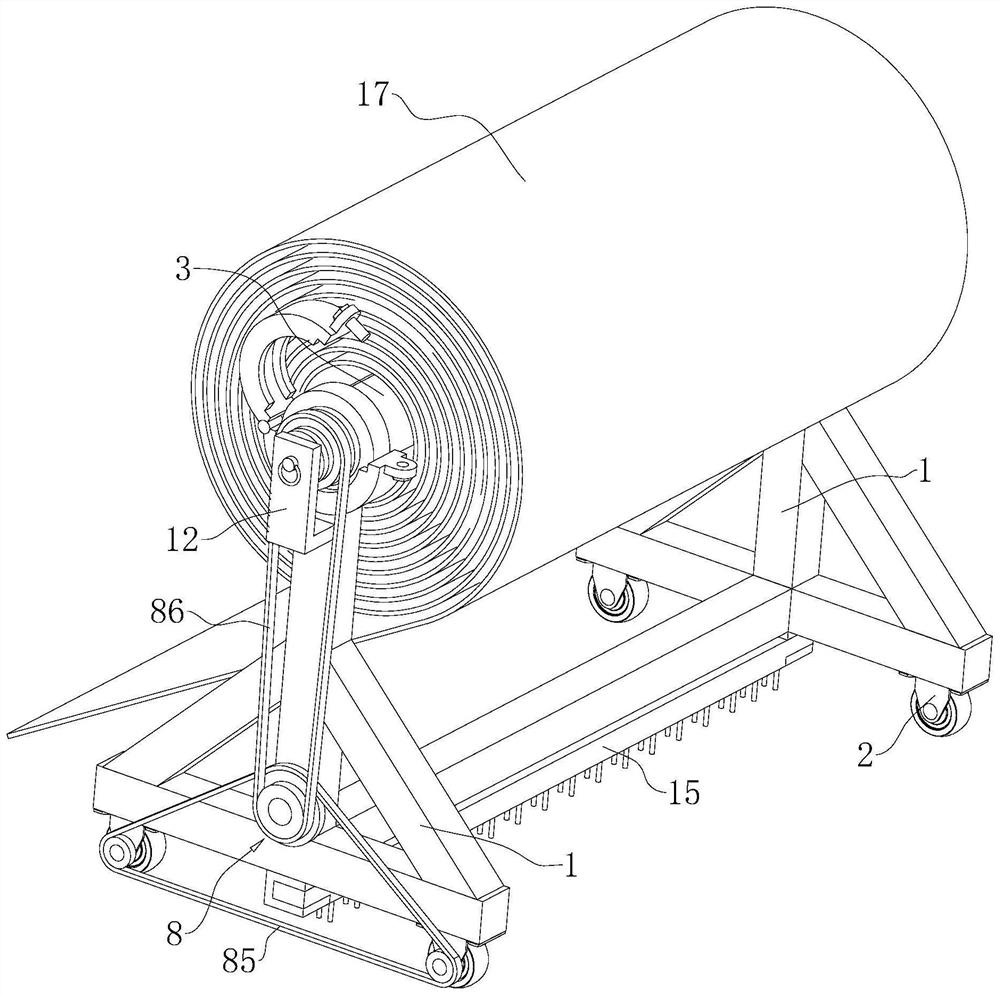

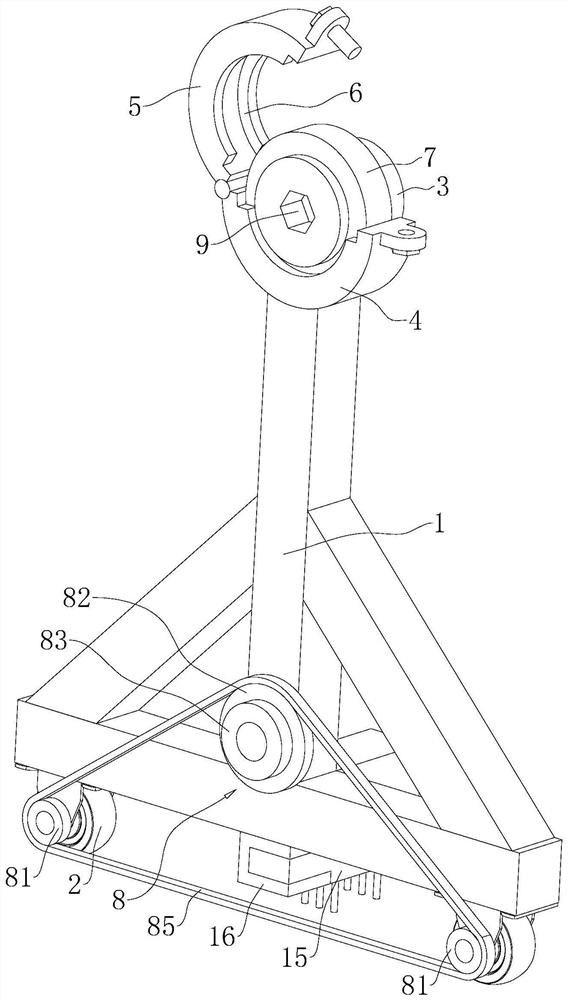

[0035] The following is attached Figure 1-4 The application is described in further detail.

[0036] The embodiment of the present application discloses a tiling device. refer to figure 1 and 2 , the tiling device includes a frame 1, the distance between the two sides of the frame 1 is equal to the width of the roadbed; four groups of rollers 2 are fixed on the lower end of the frame 1, and the upper end of the frame 1 is rotatably connected with a rotating shaft 3, and the rotating shaft 3 is covered Geotextile roll; when the frame 1 was transported forward, the geotextile 17 was unrolled and laid flat on the lower bearing layer.

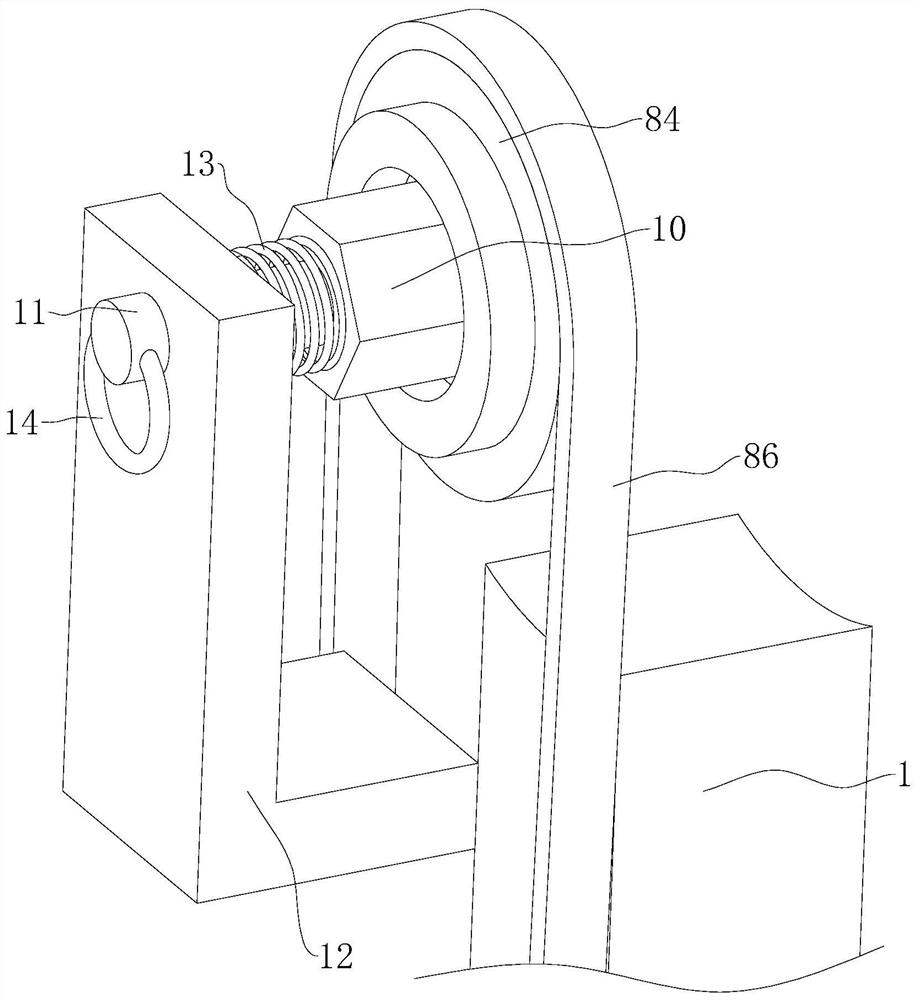

[0037] Wherein, the upper ends of both sides of the frame 1 are respectively fixed with a half ring 1 4, the opening of the half ring 1 4 faces upwards, and the opening end of the half ring 1 4 is connected with a half ring 2 5 by hinge rotation, and the half ring 5 is connected with the half ring 4. The other end of the second 5 relative to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com