Vacuum valve with locking function

A vacuum valve and function technology, applied in valve details, valve device, sliding valve, etc., can solve the problems of vacuum valve not having self-locking function, change, valve port fluid leakage system pressure, etc., to reduce fluid leakage and friction. and wear, reducing the effect of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

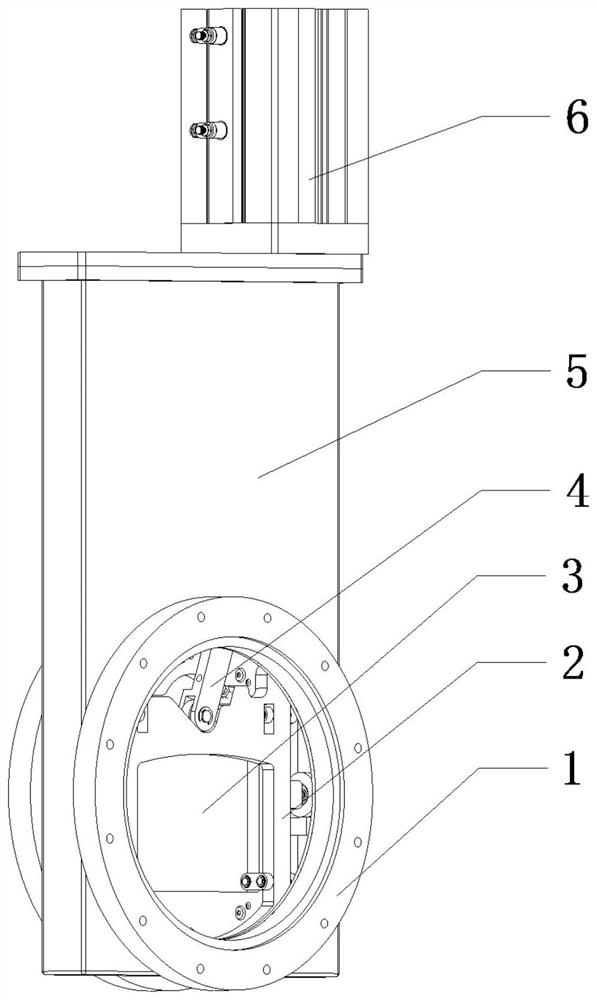

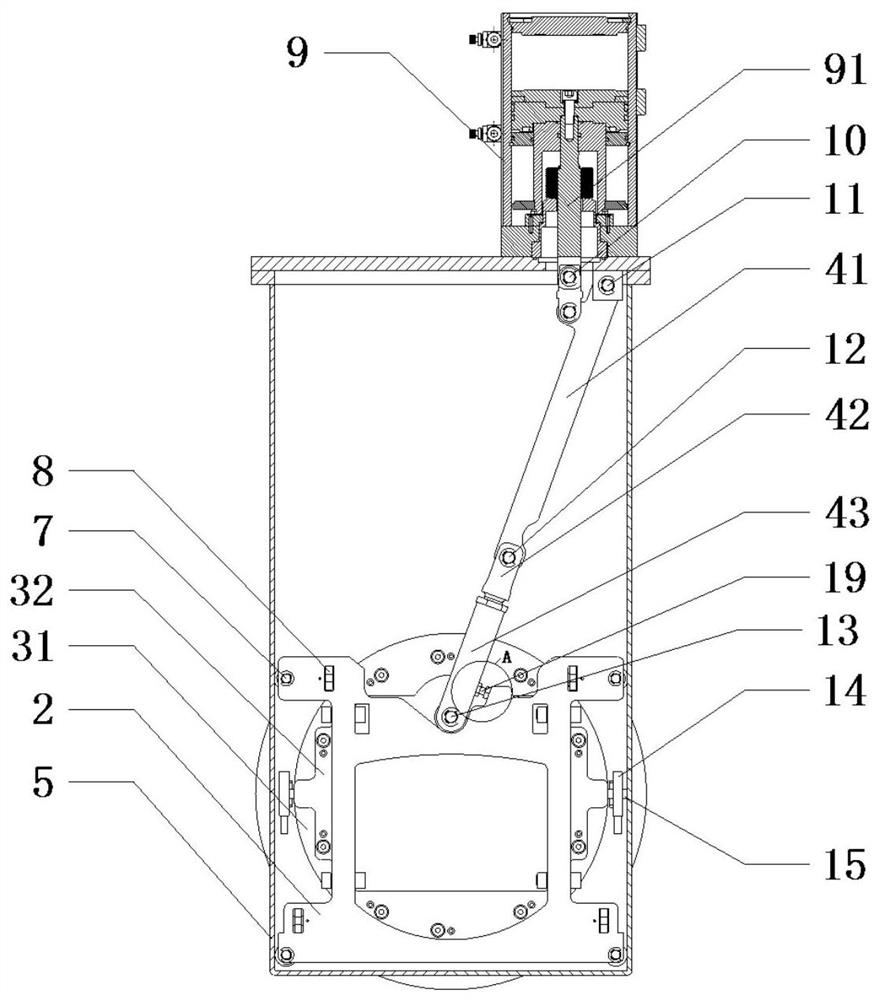

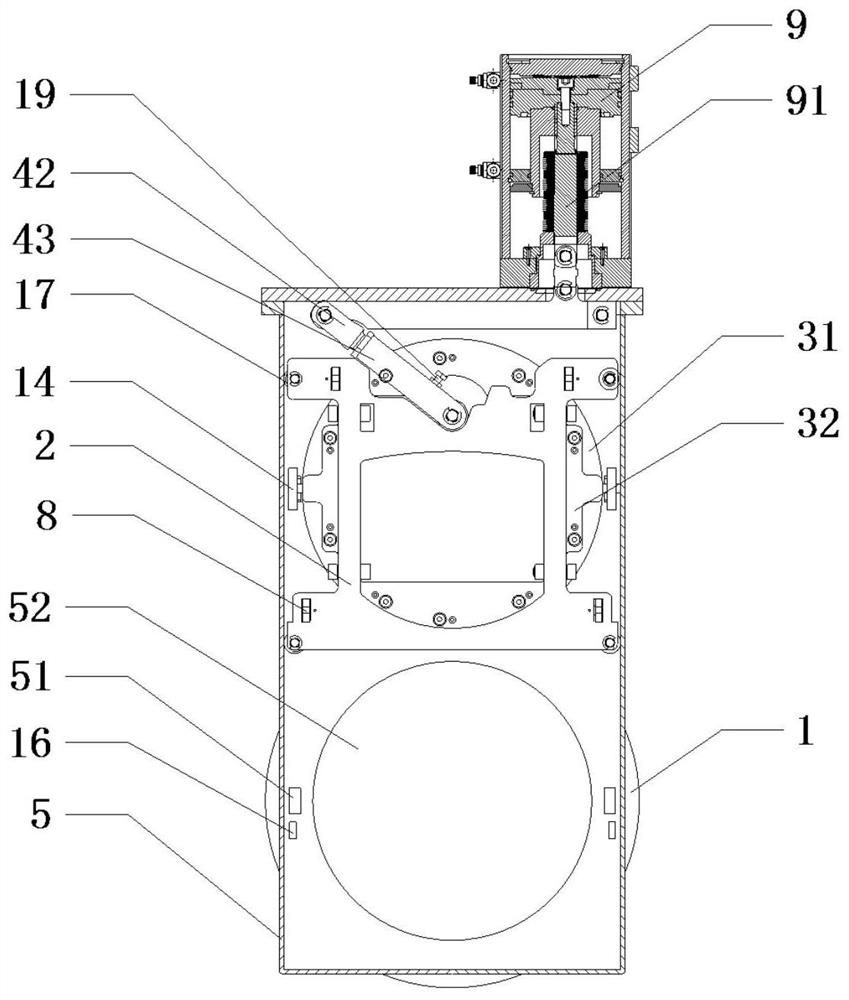

[0032] Such as Figure 1 to Figure 6 As shown, a vacuum valve with a locking function includes a valve body 5 and a driving mechanism 6, a valve port 52 is opened on the valve body 5, flanges 1 are installed on opposite sides of the valve body 5, and the driving mechanism 6 is connected with Extending to the connecting rod assembly 4 in the valve body 5, the connecting rod assembly 4 is connected with the support plate 2 through the lower shaft 13, and the support plate 2 is connected with the valve core assembly 3 which can close the valve port 52 through the cam 18, and the connecting rod assembly 4 is A limiter 19 that can be in contact with the support plate 2 is also installed, and the connecting rod assembly 4 can be extended into a straight line.

[0033] Working principle: the driving mechanism 6 pushes the connecting rod assembly 4 to stretch out, and the connecting rod assembly 4 then drives the support plate 2 and the valve core assembly 3 to move toward the valve p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com