Anti-seismic support and assembling method thereof

A technology of anti-seismic support and assembly method, which is applied in the direction of pipeline supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problem of adjusting the position, angle and number of inclined bars, reducing the service life of inclined bars and support plates, and is not applicable Pipeline installation and other issues to achieve the effect of reducing resource waste and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

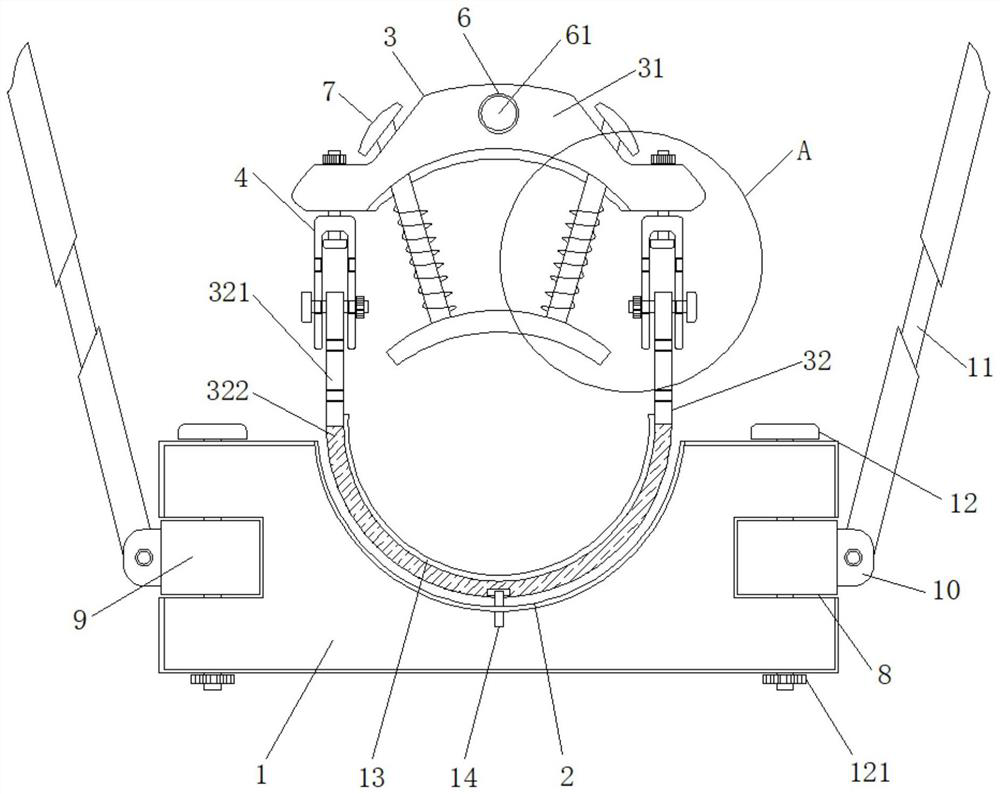

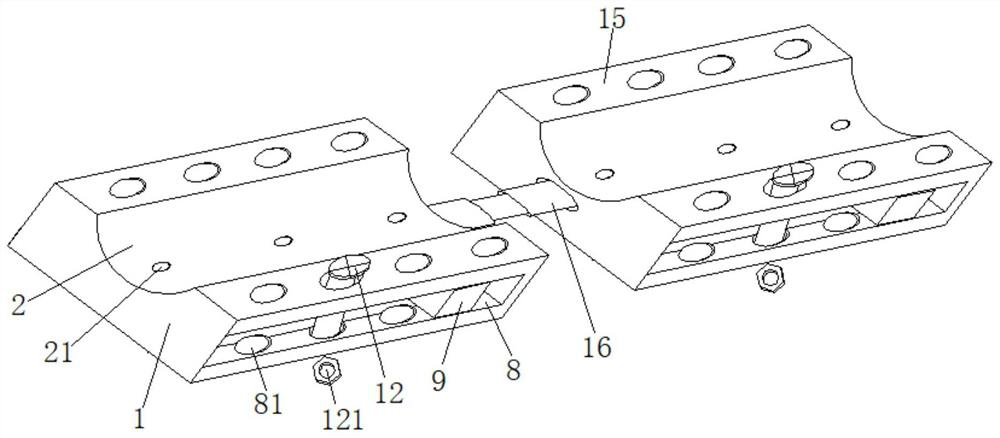

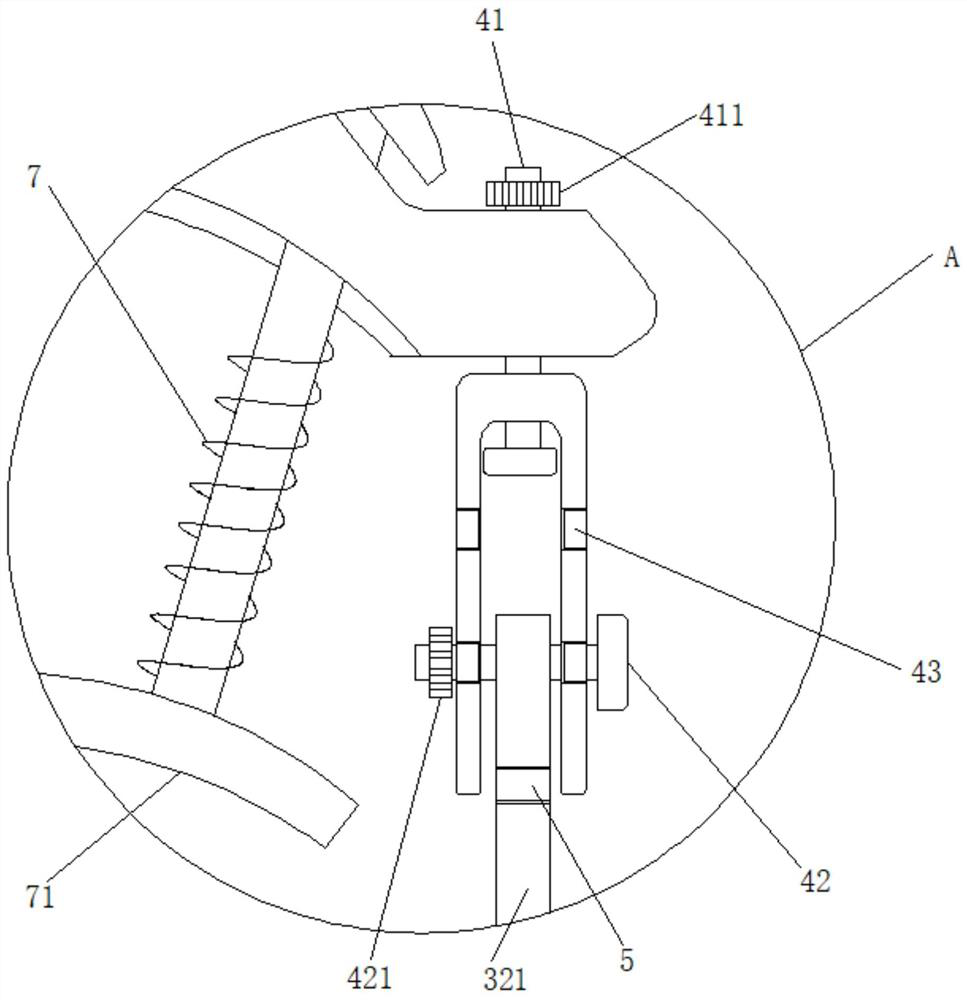

[0031] see Figure 1 to Figure 3 , an embodiment provided by the present invention: an anti-seismic bracket, comprising a first support plate 1 and a load-bearing assembly 3, an arc-shaped groove 2 for supporting the load-bearing assembly 3 is opened in the top surface of the first support plate 1, and the bearing The assembly 3 includes an upper bearing 31, a lower bearing 32 and a connecting piece 4. The two ends of the upper bearing 31 are connected to the two ends of the lower bearing 32 through the connecting piece 4. The lower bearing 32 is divided into two vertical parts. 321 and an arc portion 322, and the two vertical portions 321 are respectively arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com