Automatic precise defrosting control method and device, and heat pump water heater

A control method and defrosting time technology, applied in the field of equipment, automatic and precise defrosting control method, heat pump water heater, can solve the problems that the unit cannot accurately judge the frosting state and unit status, and the defrosting effect is not good, and achieve Avoid long-term harsh operating conditions and low heating capacity, improve user experience, and achieve the effect of precise defrosting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

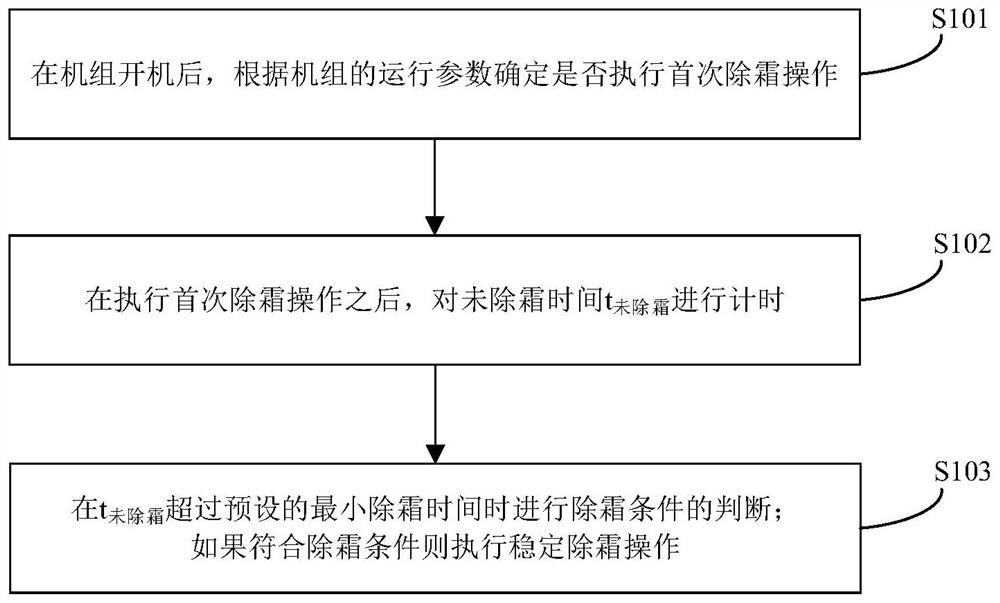

[0029] figure 1 is a flowchart of a defrosting control method according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0030] Step S101, after the unit is turned on, determine whether to perform the first defrosting operation according to the operating parameters of the unit;

[0031] Step S102, after performing the first defrosting operation, the non-defrosting time t 未除霜 timekeeping;

[0032] Step S103, at t 未除霜 When the preset minimum defrosting time is exceeded, the defrosting condition is judged; if the defrosting condition is met, the stable defrosting operation is performed.

[0033] It should be noted that the present invention is applicable to heat pump water heaters with electronic expansion valves as throttling devices and automatic defrosting functions. Based on this embodiment, it is possible to accurately determine the frosting state of the unit, to defrost accurately without increasing costs,...

Embodiment 2

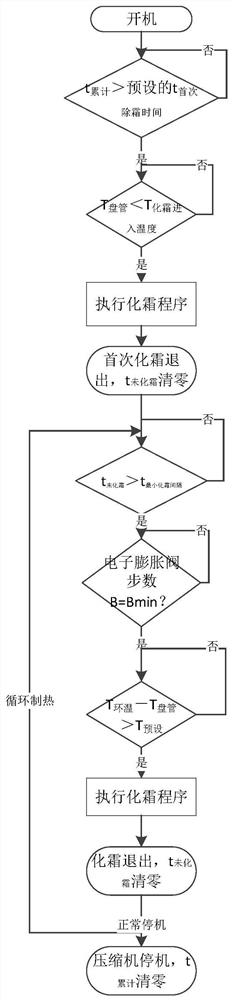

[0042] figure 2 It is a flow chart of defrosting control of a heat pump water heater according to an embodiment of the present invention, such as figure 2 As shown, the process includes the following steps:

[0043] 1. When the unit is turned on, the timer starts counting t 未除霜 and t 累计 , and check t in real time 累计 . when t 累计 greater than the preset t 首次除霜时间 , the crew starts to judge T 盘管 Whether the temperature condition of the first defrosting coil is met, specifically, judge T 盘管 未除霜 .

[0044] 2. After that, enter the non-initial defrosting control program. Unit real-time inspection t 未除霜 Whether it is greater than the preset minimum defrosting time (it can be understood as the defrosting interval time), if not satisfied, re-inspect, when the above conditions are met, start to judge the defrosting conditions:

[0045] 1) Check the number of steps B of the electronic expansion valve. The minimum number of steps of the electronic expansion valve is usually a ...

Embodiment 3

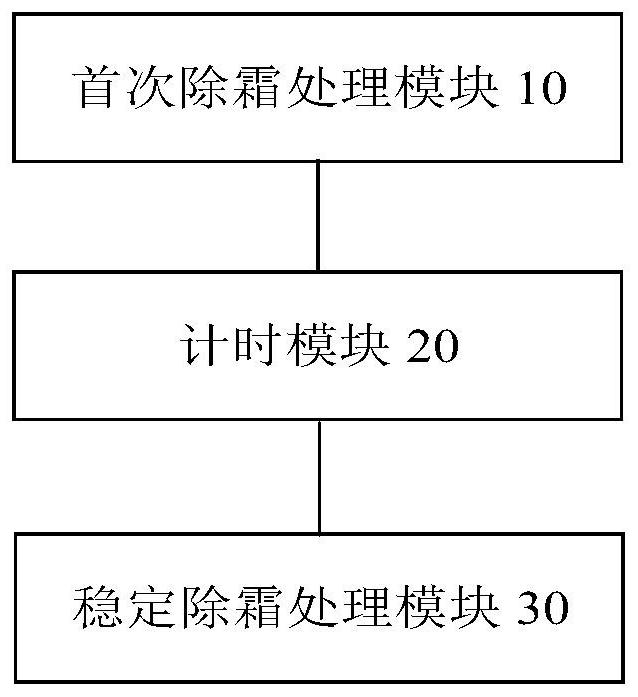

[0051] corresponds to figure 1 In the defrosting control method introduced, this embodiment provides a defrosting control device, such as image 3 The structural block diagram of the defrosting control device shown, the device includes:

[0052] The first defrosting processing module 10 is used to determine whether to perform the first defrosting operation according to the operating parameters of the unit after the unit is turned on;

[0053] Timing module 20, used for accumulating running time t of the compressor 累计 and non-defrosting time t 未除霜 timekeeping;

[0054] The stable defrosting processing module 30 is used for performing the first defrosting operation, at t 未除霜 When the preset minimum defrosting time is exceeded, the defrosting condition is judged; if the defrosting condition is met, the stable defrosting operation is performed.

[0055] Based on this embodiment, it is possible to accurately determine the frosting state of the unit, to defrost accurately witho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com