Stock bin material weighing method, stock bin, device and computer readable storage medium

A weighing method and weighing device technology, applied in the field of weighing, can solve the problems of high cost and the inability of a single door structure to take into account both aggregate weighing speed and weighing accuracy, so as to ensure accuracy and balance weighing efficiency And weighing accuracy, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a method for weighing materials in a silo. The bottom of the silo 100 is provided with a silo door 110 for controlling the falling of materials in the silo 100 and a weighing device for weighing the materials falling through the silo door 110 120.

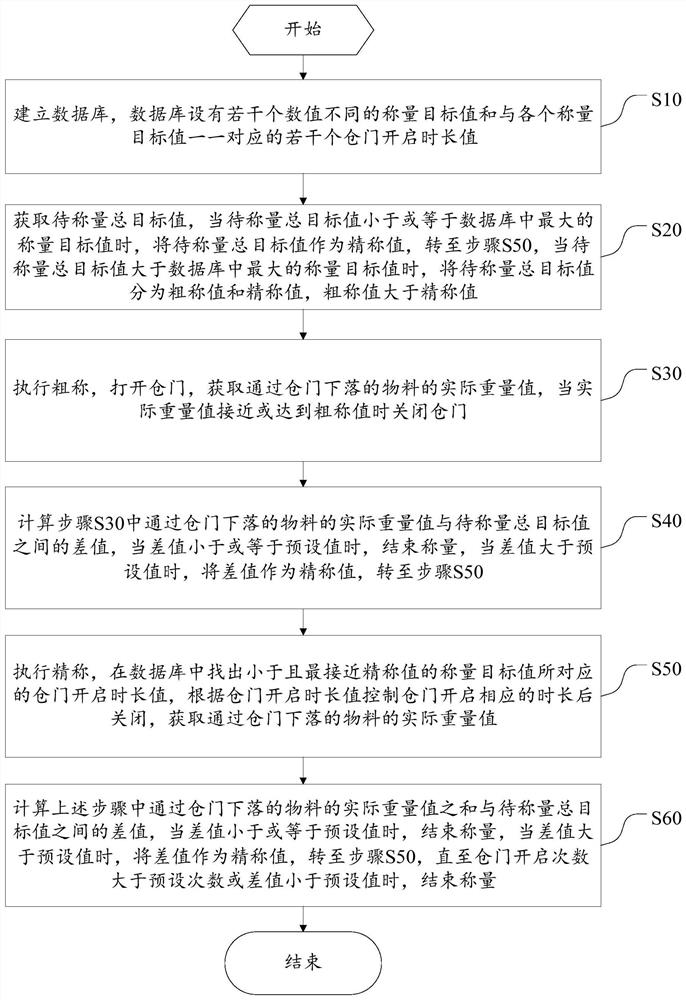

[0057] like figure 1 As shown, the weighing method of silo material includes the following steps:

[0058] Step S10, establishing a database, the database is provided with several weighing target values with different numerical values and several warehouse door opening duration values corresponding to each weighing target value one-to-one;

[0059] In step S20, the total target value to be weighed is obtained, and when the total target value to be weighed is less than or equal to the largest weighing target value in the database, the total target value to be weighed is used as the fine weighing value, and the process goes to step S50, When the total weighing target value is greater than the l...

Embodiment 2

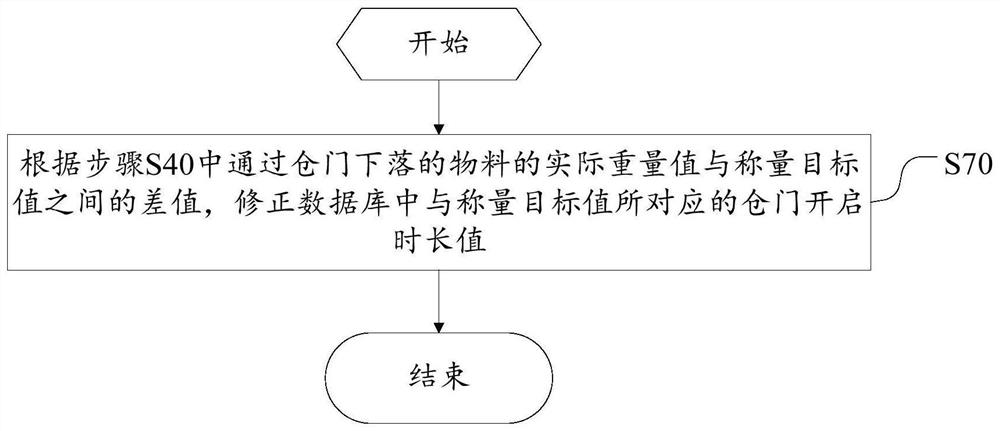

[0074] like figure 2 As shown, this embodiment provides a method for weighing materials in a silo. In addition to the technical features of the above-mentioned embodiments, this embodiment further includes the following technical features.

[0075] The weighing method of the material in the silo also includes the following steps:

[0076] Step S70, according to the difference between the actual weight value of the material dropped through the warehouse door in step S40 and the weighing target value, correct the warehouse door opening duration value corresponding to the weighing target value in the database.

[0077] The purpose of this embodiment is to adjust the opening time value of the warehouse door according to the weighing and feeding situation. The difference between the actual weight value and the weighing target value represents the progress of the feed weighing. If the difference between the actual weight value and the weighing target value is large, the door openi...

Embodiment 3

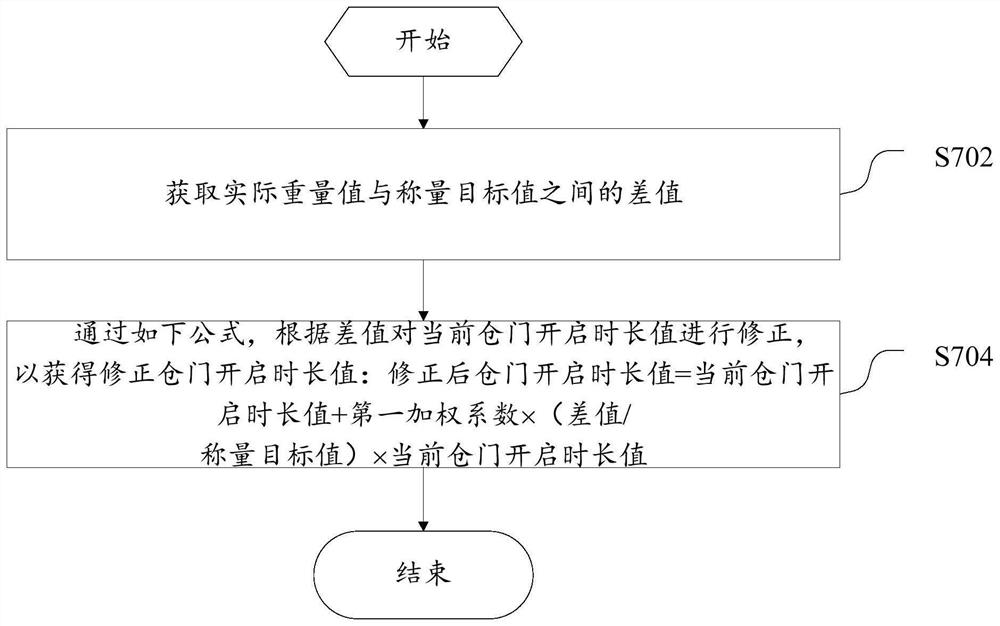

[0079] like image 3 As shown, this embodiment provides a method for weighing materials in a silo. In addition to the technical features of the above-mentioned embodiments, this embodiment further includes the following technical features.

[0080] Step S70 specifically includes:

[0081] Step S702, obtaining the difference between the actual weight value and the weighing target value;

[0082] Step S704, through the following formula, correct the current warehouse door opening duration value according to the difference, so as to obtain the corrected warehouse door opening duration value: After the correction, the warehouse door opening duration value=current warehouse door opening duration value+first weighting coefficient×( Difference value / Weighing target value)×current door opening time value.

[0083] This embodiment provides a specific correction method for correcting the opening duration value of the warehouse door. Among them, the first weighting coefficient can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com