Tea leaf tender shoot picking machine and method

A technology for picking machines and tea leaves, which is applied to picking machines, harvesters, agricultural machinery and implements, etc., can solve problems such as affecting the quality of tea leaves and damage to tender buds, so as to avoid high costs, save costs, save use costs and upgrade costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

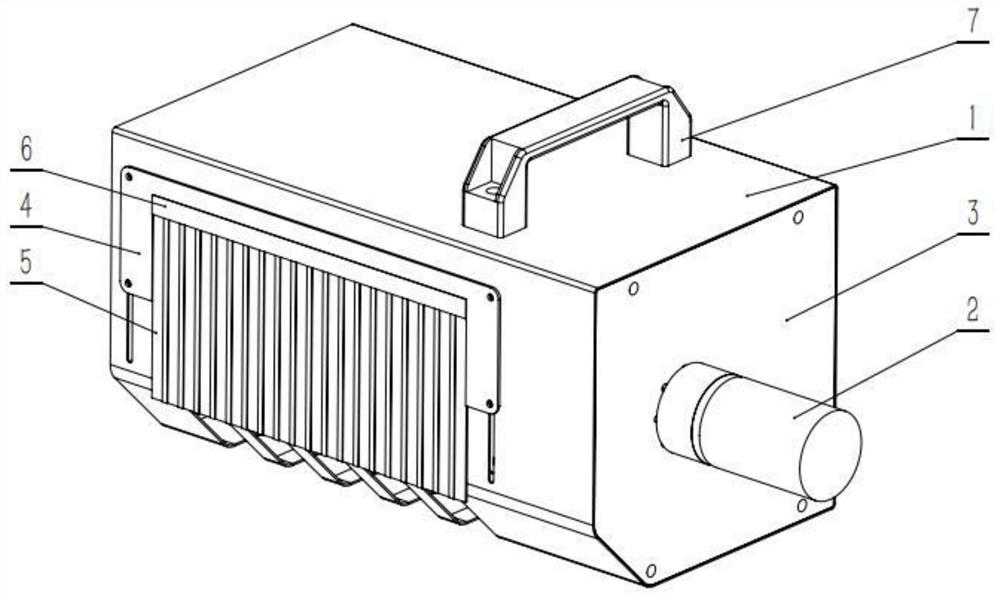

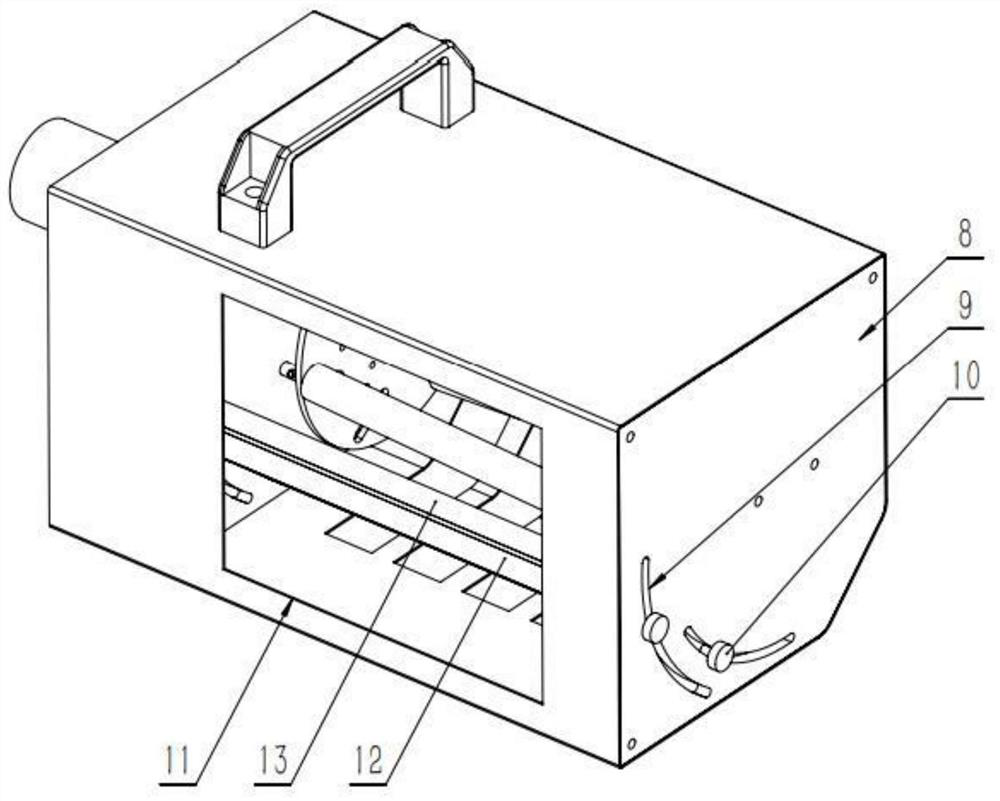

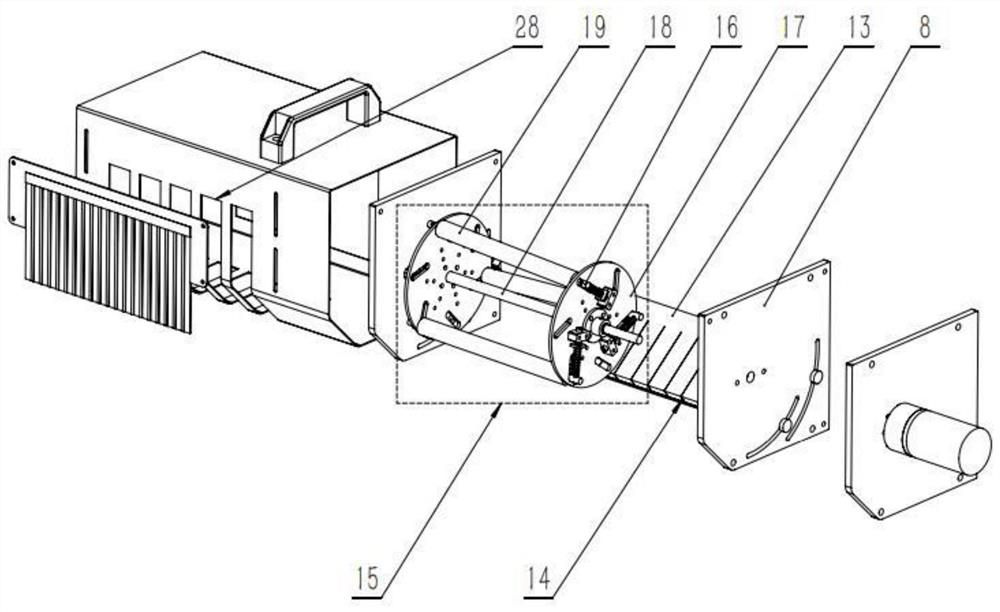

[0034] Such as figure 1 and figure 2 As shown, the tea bud picking machine includes a chassis 1, a tea extraction module 15 located in the chassis, guide groove plates 8 respectively located at both ends of the chassis, and a drive motor 2 located on one side of the chassis. The drive motor is connected to the right side of the chassis through the motor fixing plate 3; the rear of the chassis is provided with a discharge port 11, and the front part is provided with a feed port 28; It is fixed on both sides of the left side of the cabinet; the base plate 12 is installed on the guide groove plate by hand-tightening screws 10, and the base plate can rotate with the main shaft as the center of circle in the arc guide groove; the top of the cabinet in the present invention is also equipped with a handle 7 , the handle is fixed on the top of the case with screw holes for easy use.

[0035] Further, a soft screen curtain 4 is provided at the feed inlet, and the soft screen curtain...

Embodiment 2

[0044] The difference from Example 1 is that, as Figure 7 and Figure 8 As shown, in the multi-unit tea bud picking machine described in this embodiment, there are multiple sets of tea extracting modules, and each set of tea extracting modules is a set of tea extracting units 27 . The tea extracting unit is composed of two turntables, three sets (or two or more sets) of extracting rods and a pressure regulating mechanism, and each set of tea extracting units are connected in pairs through mechanical interfaces reserved on the turntables , connected into tea extracting areas of different lengths. Each group of tea extracting units transmits power through the main shaft. The multi-unit tea bud picking machine with different picking widths can be formed by changing the chassis, the main shaft and the bottom plate of different lengths.

[0045] The multi-unit tea bud picking machine can adapt to the unstructured environment where there is no uniform standard for the width of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap