Production method of gingiva forming and alveolar bone trimming surgery guiding device and guiding device

A technology for surgical guidance and manufacturing methods, which is applied in the field of manufacturing methods and guiding devices for gingival molding and alveolar bone revision surgery, and can solve problems such as poor precision, high technical sensitivity, and long operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

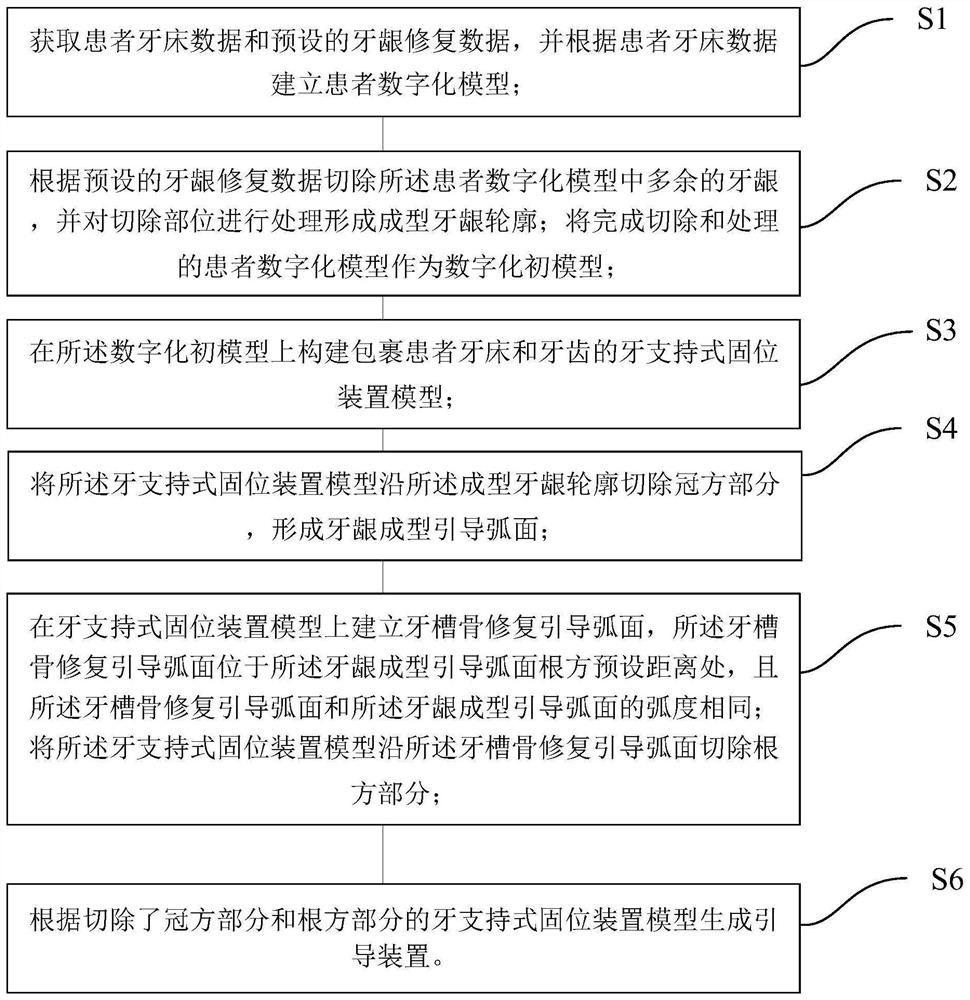

[0039] Such as Figure 1-7 As shown, the manufacturing method of the gingiva forming and alveolar bone repairing operation guiding device of the present invention comprises the following steps:

[0040] S1: Obtain the patient's gum data and preset gum restoration data, and establish a digital model of the patient based on the patient's gum data;

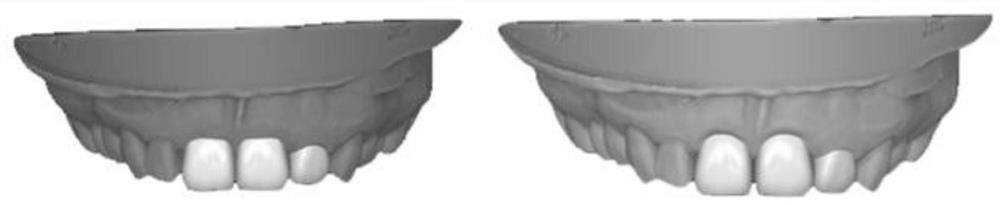

[0041] S2: Excise excess gingiva in the digital model of the patient according to the preset gingiva repair data, and process the excised part to form a gingival contour; use the patient digital model that has been resected and processed as the initial digital model;

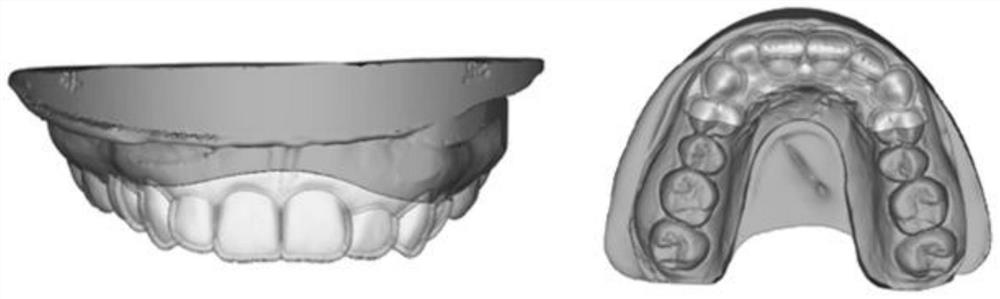

[0042] S3: constructing a tooth-supported retention device model covering the patient's gums and teeth on the digital primary model;

[0043] S4: Excise the coronal part of the tooth-supported retention device model along the contour of the formed gingiva to form a gingiva forming guiding arc surface 3;

[0044] S5: Establish the alveolar bone repair guiding arc surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com