Automatic assembling device for rubber rings of heat exchanger sheets and assembling method of automatic assembling device

An automatic assembly device and heat exchanger technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low installation efficiency, work-related accidents, etc., to improve production efficiency and product quality, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

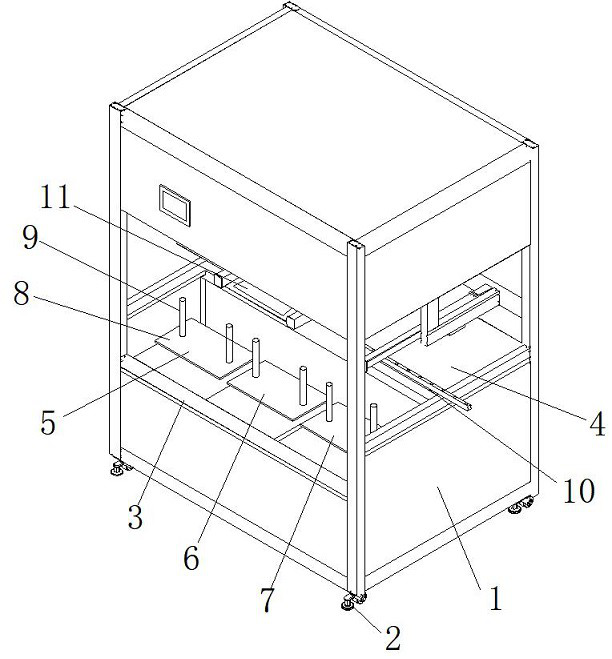

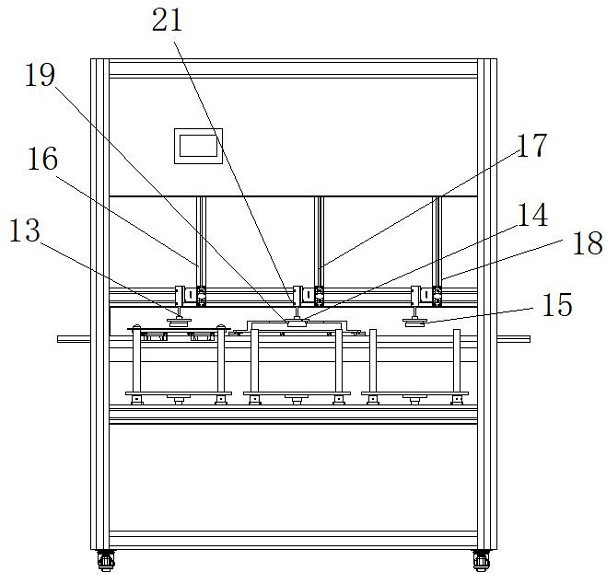

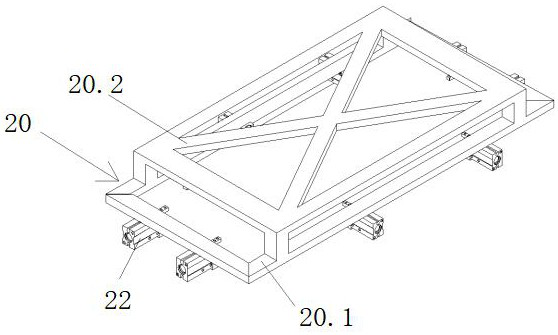

[0027] see Figure 1 to Figure 8 , the present invention relates to an automatic rubber ring assembly device for heat exchanger plates, which includes a frame 1, the frame 1 is surrounded by columns, the middle is a working area, and the bottom of the frame 1 is provided with mobile casters 2, so as to facilitate the movement of the machine To each position in the workshop, the working area in the middle of the frame 1 is divided into front and rear parts, the front side is the holding platform 3, and the rear side is the workbench 4.

[0028] The holding platform 3 is successively from left to right a plate feeding station 5, an apron feeding station 6, and a finished product unloading station 7. These three stations are respectively fixed with a placing platform 8 and a placing platform 8. Vertical positioning columns 9 are fixed on the left and right sides of the board, wherein the plates without aprons are stacked on the placement table 8 of the sheet feeding station 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com