Hole drilling mechanism for furniture production

A furniture and lifting mechanism technology, applied in the field of hole-taking mechanism in furniture production, can solve problems such as damage to the board surface, enlargement of the opening position, affecting processing and production, etc., to ensure integrity, reduce the process of repairing holes, and improve drilling. The effect of hole efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

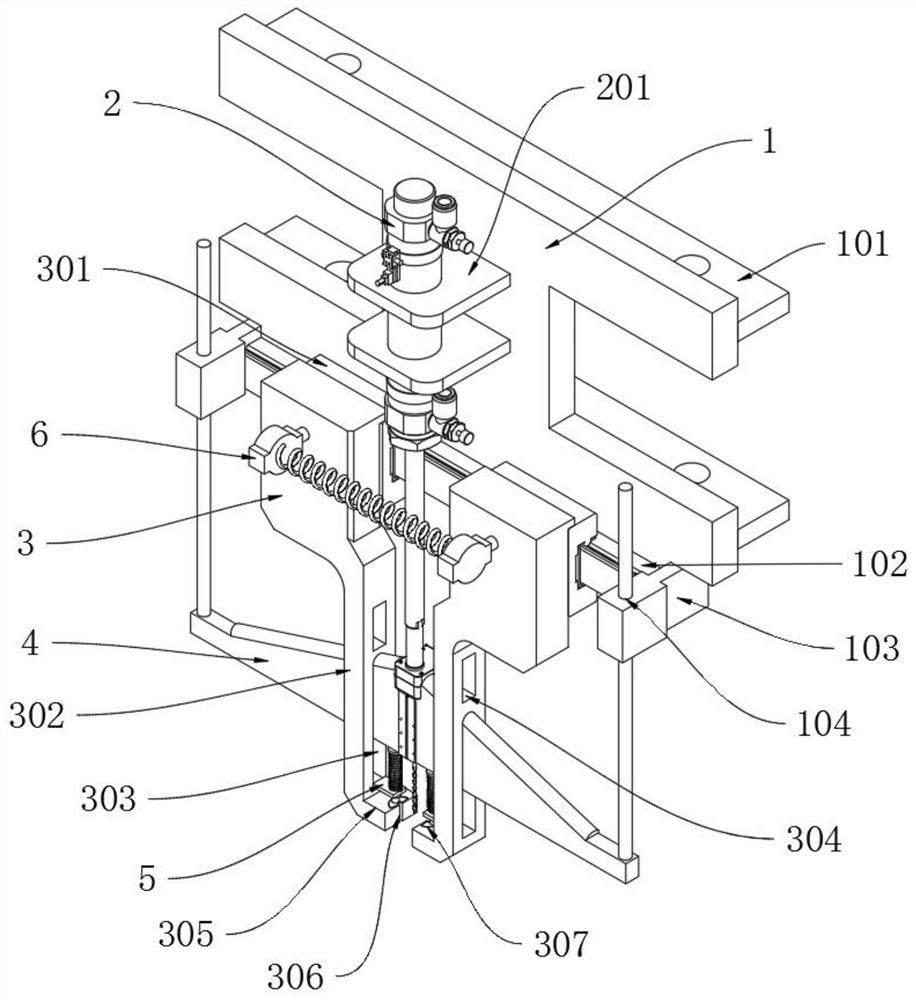

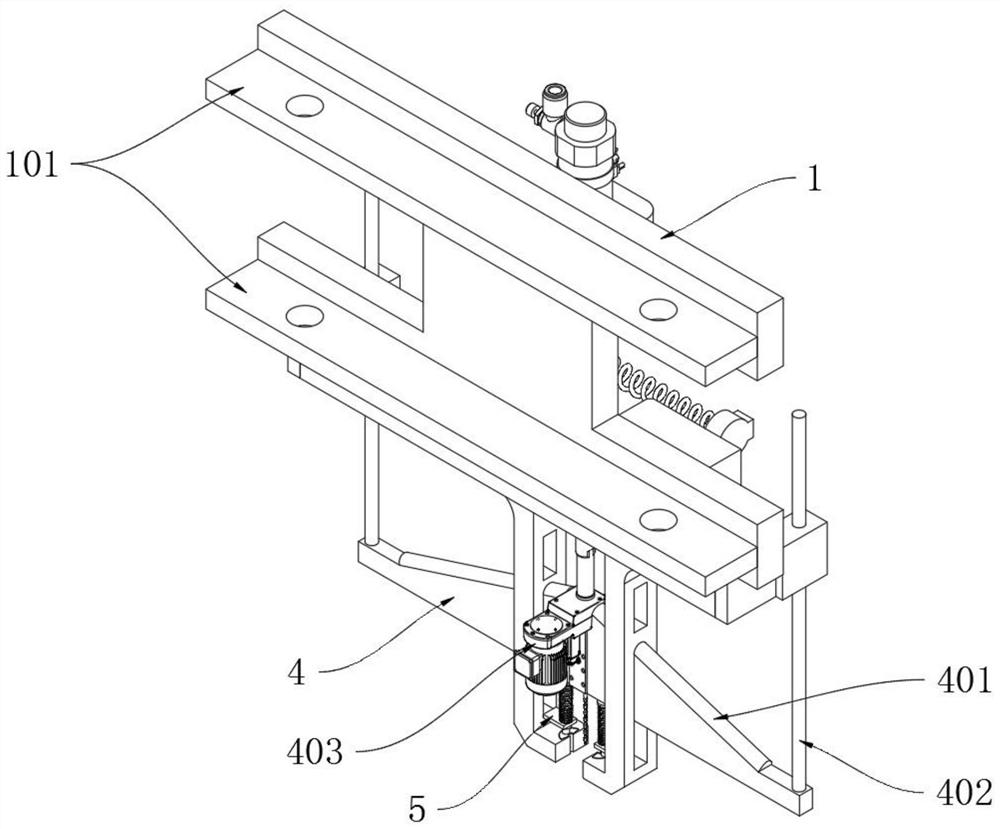

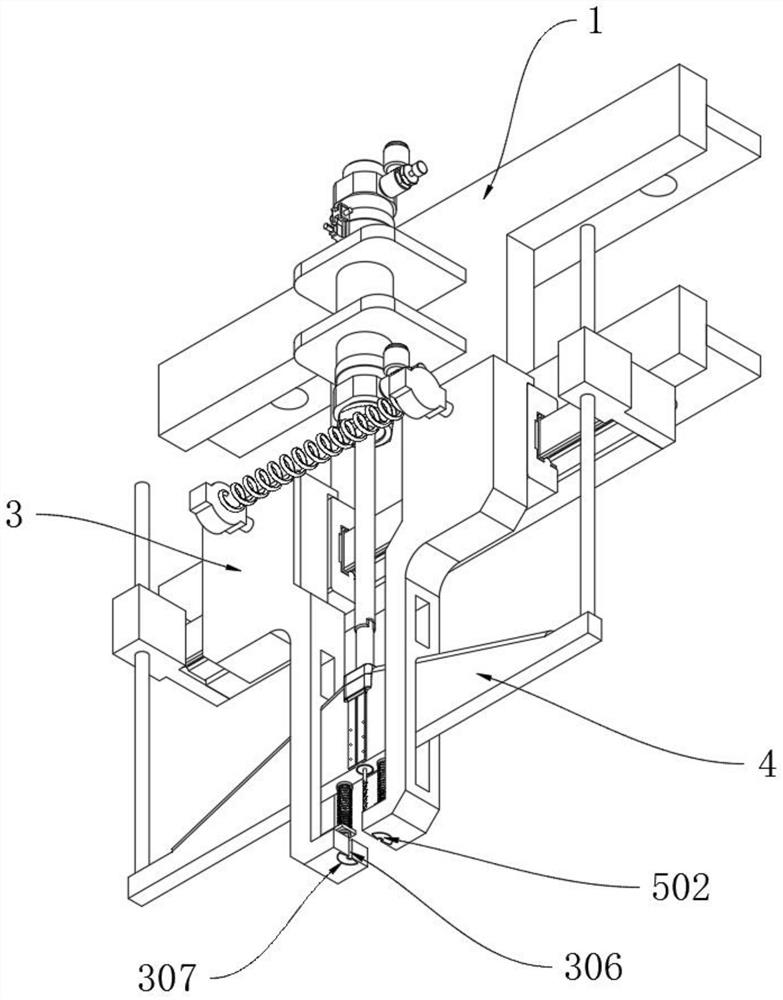

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The invention provides a hole-taking mechanism for furniture production, comprising a mounting frame 1; the main body of the mounting frame 1 is an I-shaped structure, and a lifting mechanism 2 is fixed vertically in the middle of the front side wall of the mounting frame 1; the mounting frame 1 Two symmetrical auxiliary positioning mechanisms 3 are vertically slidably installed on the lower edge of the front side wall; a hole-taking mechanism 4 is installed horizontally slidingly between the two auxiliary positioning mechanisms 3; the lower end of the auxiliary positioning mechanism 3 and the hole-taking mechanism 4 A vertical crimping mechanism 5 is fixedly installed at the position corresponding to the lower end; the crimping mechanism 5 includes a crimping inner column 501, a crimping arc block 502, a stopper 503, a crimping jacket 504, an inner spring 505 and an outer spring 506 , the outer end of the crimpi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap