Triangular crawler-type inspection robot

An inspection robot and triangular crawler technology, applied in the field of robots, can solve the problems of difficulty in manual inspection, low inspection efficiency, and high labor intensity, and achieve high inspection efficiency, convenient inspection methods, and reduced labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

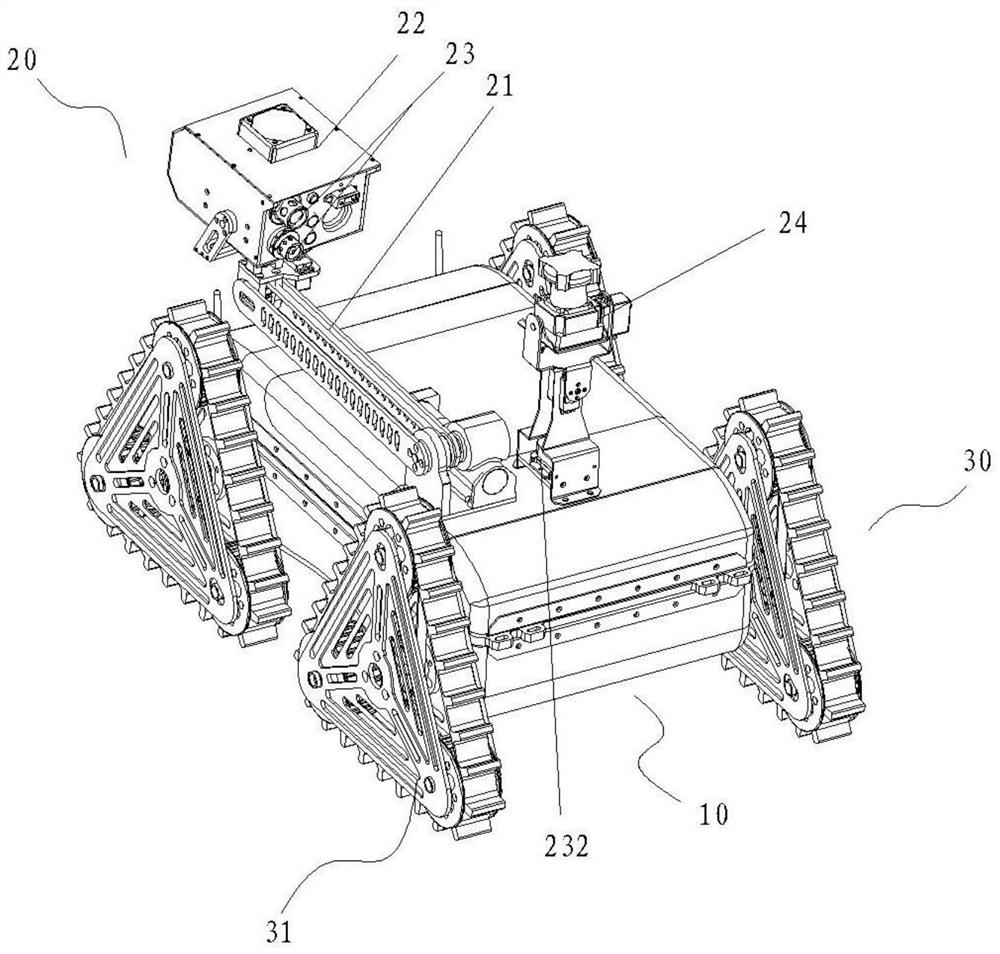

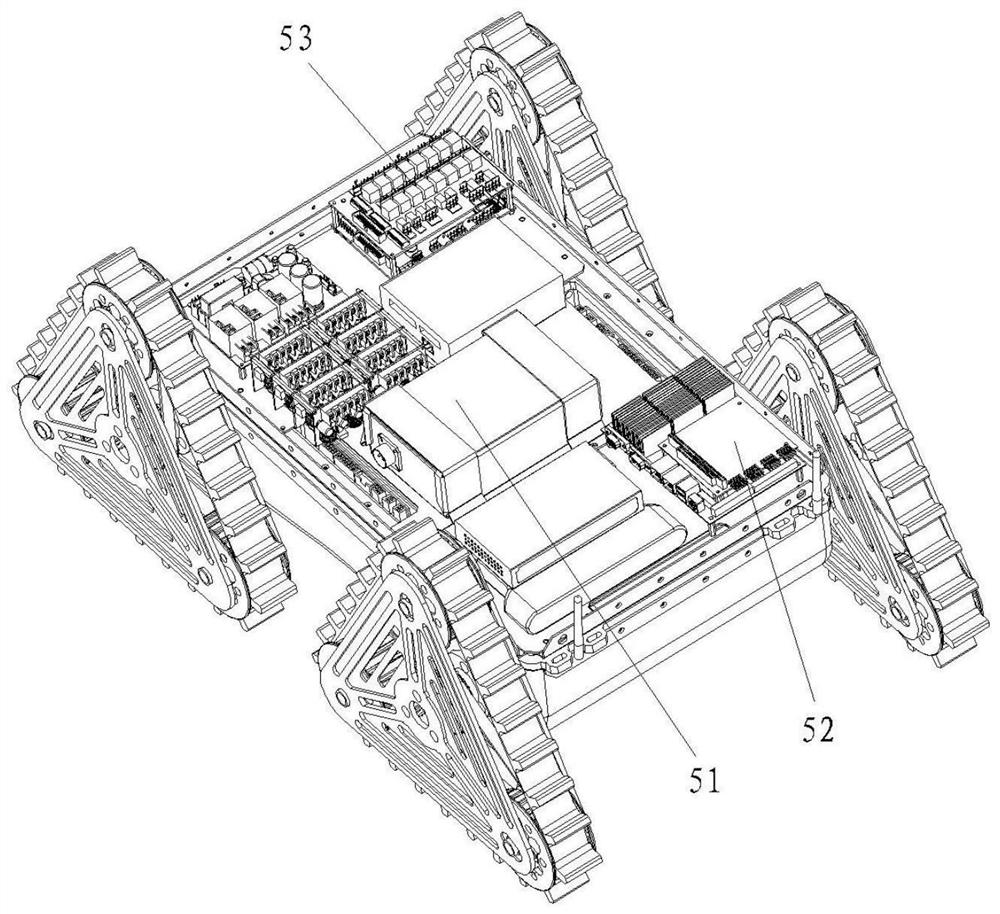

[0028] figure 1 It is a schematic diagram of the overall structure of the present invention; figure 2 Schematic diagram of the layout of the upper layer of the rack; image 3 Schematic diagram of the layout of the lower layer of the rack; Figure 4 Schematic diagram of the power assembly structure; Figure 5 It is a schematic diagram of the top view structure of the power assembly; Figure 6 It is a structural schematic diagram of the walking assembly (30); Figure 7 Schematic diagram of the local structure of the power components figure 1 ; Figure 8 Schematic diagram of the local structure of the power components figure 2 ; Figure 9 It is a schematic diagram of the structure of the mechanical arm;

[0029] As shown in the figure: the triangular crawler-type inspection robot of this embodiment includes a frame 10, a walking device and a sensing device 20, and the sensing device is installed on the frame for sensing the external environment. There are at least two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com