Vortex type radiator

A radiator and vortex technology, applied in the field of vortex radiators, can solve the problems of low heat dissipation efficiency of radiators, achieve high utilization efficiency, speed up heat dissipation efficiency, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

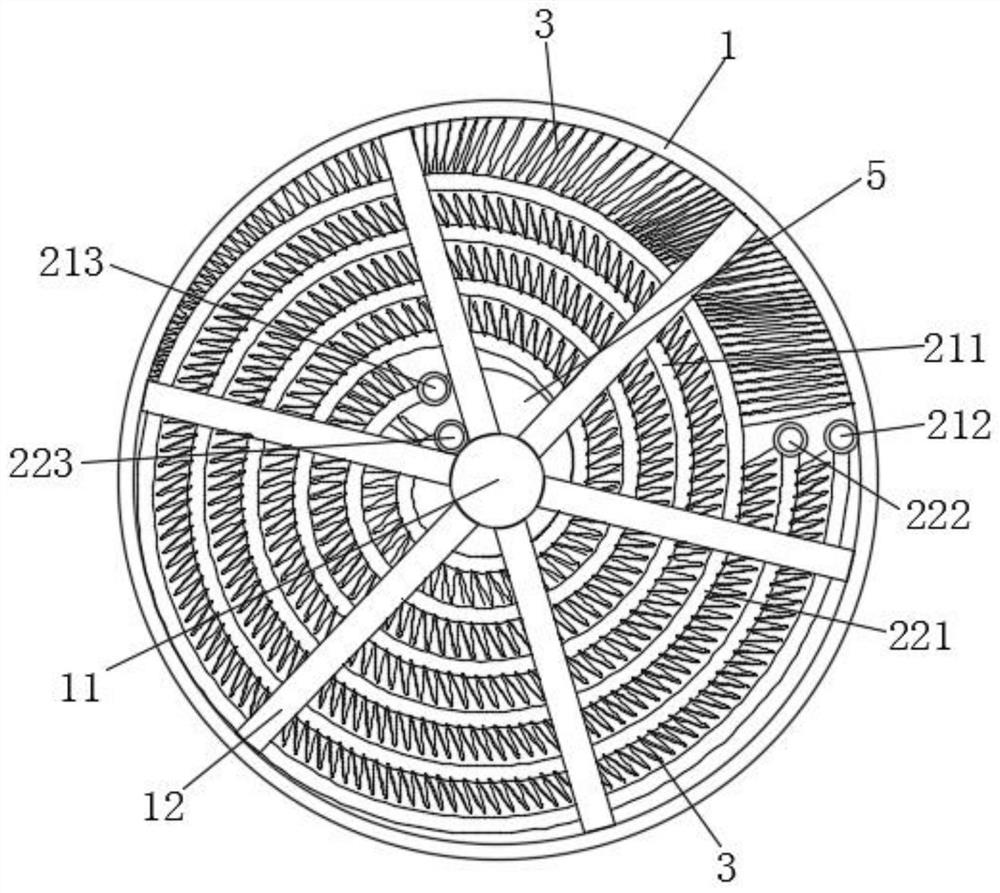

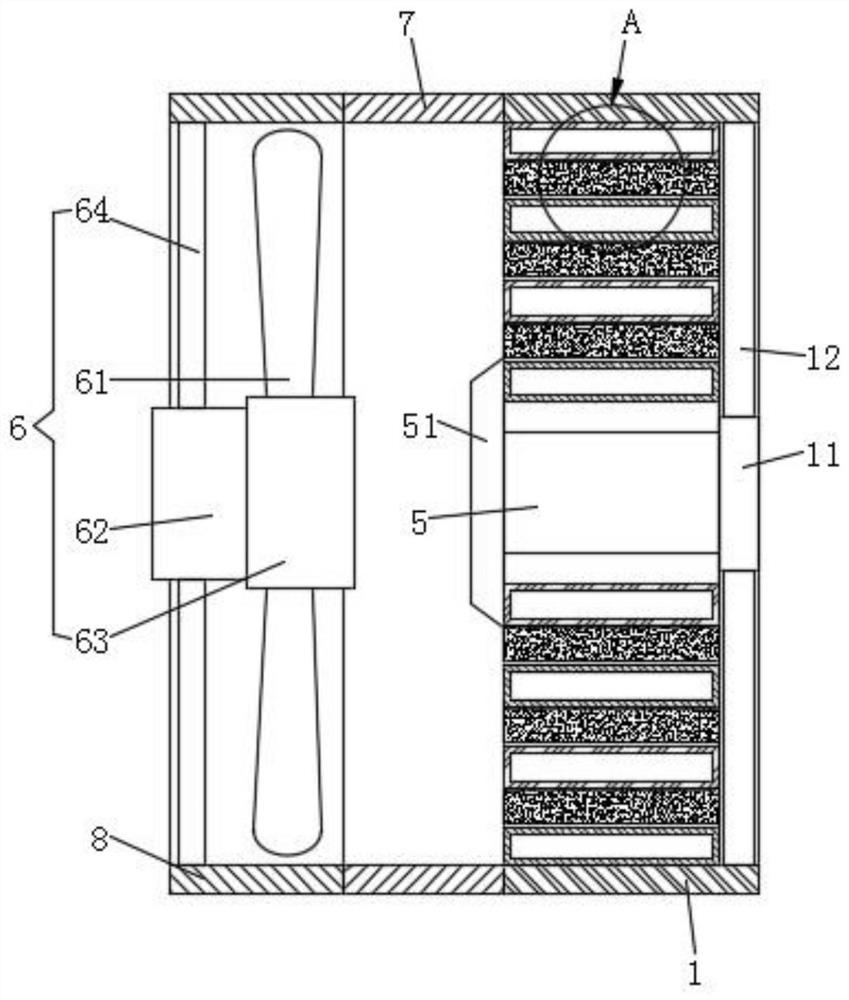

[0035] refer to image 3 , this embodiment discloses a scroll radiator, including a heat dissipation channel 7 . Along the front and rear sides of the central axis of the heat dissipation passage 7, the coaxial heat sink housing 1 and the heat dissipation fan housing 8 are sequentially connected by bolts. The heat dissipation channel 7, the heat sink shell 1 and the heat dissipation fan shell 8 are circular shells with equal diameters. The cooling fan 6 with the wind direction facing the cooling fin housing 1 is installed in the cooling fan housing 8 . combined reference figure 1 , the channel center of the heat sink shell 1 is provided with a fixed plate 11 , and the fixed plate 11 is fixed to the inner wall of the heat sink shell 1 through a connecting rod 12 . One end of the fixing plate 11 facing the cooling fan 6 is fixed with a connecting column 5 whose horizontal centerline is parallel to the centerline of the cooling fan 6 through bolts.

[0036] refer to figure 1...

Embodiment 2

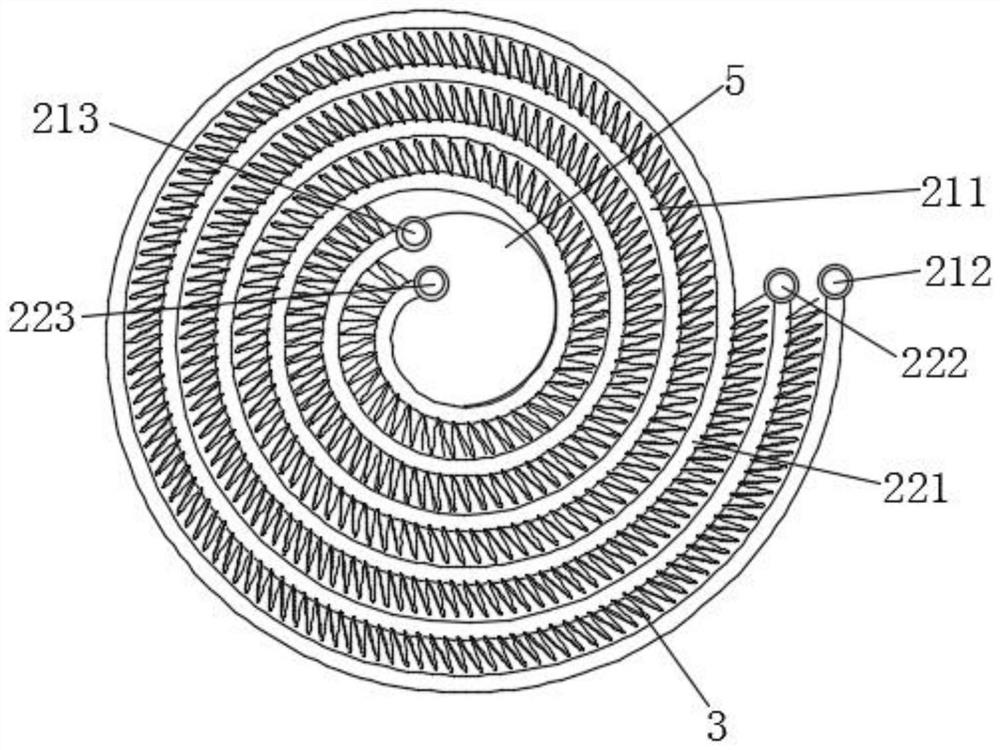

[0047] refer to Figure 5 The difference between the second embodiment and the first embodiment is that the outer circle of the connecting column 5 is only wound with a spiral third channel 231 once. A cooling fin 3 with the same vortex pitch, vortex direction and curvature as the vortex gap is embedded in the vortex gap of the third channel 231 . A third outlet 233 is defined at an inner end of the third channel 231 . A third inlet 232 is defined at the outer end of the third channel 231 .

[0048] Compared with Embodiment 1, in this embodiment, the outer circumference of the connecting column 5 is wound with a third passage 231. When there is only one cooling object, the structure of Embodiment 2 is used to make the cooling object in the third passage 231 In the case of being completely covered by the wind direction of the fan, the material consumption of the vortex radiator is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com