Creep irradiation device suitable for stress static loading

A technology of static loading and irradiation device, applied in measurement device, material analysis using wave/particle radiation, and testing material strength using applied stable tension/pressure, etc., can solve problems such as increasing technical difficulty and being unsuitable for research reactors , to achieve the effect of improving the reliability and safety of the test and the compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

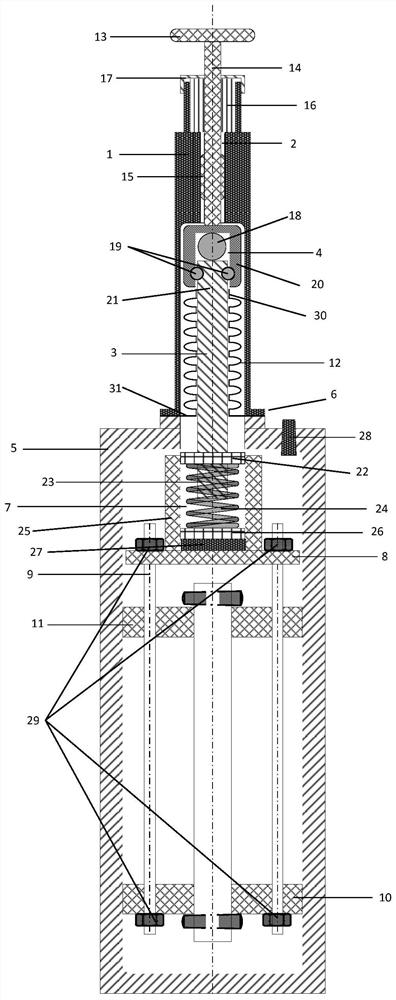

[0022] Such as figure 1 As shown, the creep irradiation device suitable for static stress loading of the present invention includes an upper casing 1, a lower casing 5, a threaded power transmission mechanism 2 and a displacement rod 3 placed in the upper casing 1, and a displacement rod 3 placed in the lower casing. The force measuring component 7, the movable sample holder I 8, the movable sample holder II 10, and the fixed sample holder 11 in the body 5; wherein, the upper casing 1 and the lower casing 5 are connected to each other by a screw cap or Welded and sealed connection. The threaded power transmission mechanism 2 and the displacement rod 3 are connected by a direction changing connector 4, and the displacement rod 3 passes through the sealing plate 6 on the top of the lower housing 5, passes through the force measuring component 7 and the movable sample holder 1 8 is connected, the movable sample rack I 8 is connected to the movable sample rack II 10 through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com