Robot safety logic control system

A technology of control system and safety logic, applied in general control system, control/regulation system, program control in sequence/logic controller, etc., can solve the problem of low safety level and achieve the effect of improving safety control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

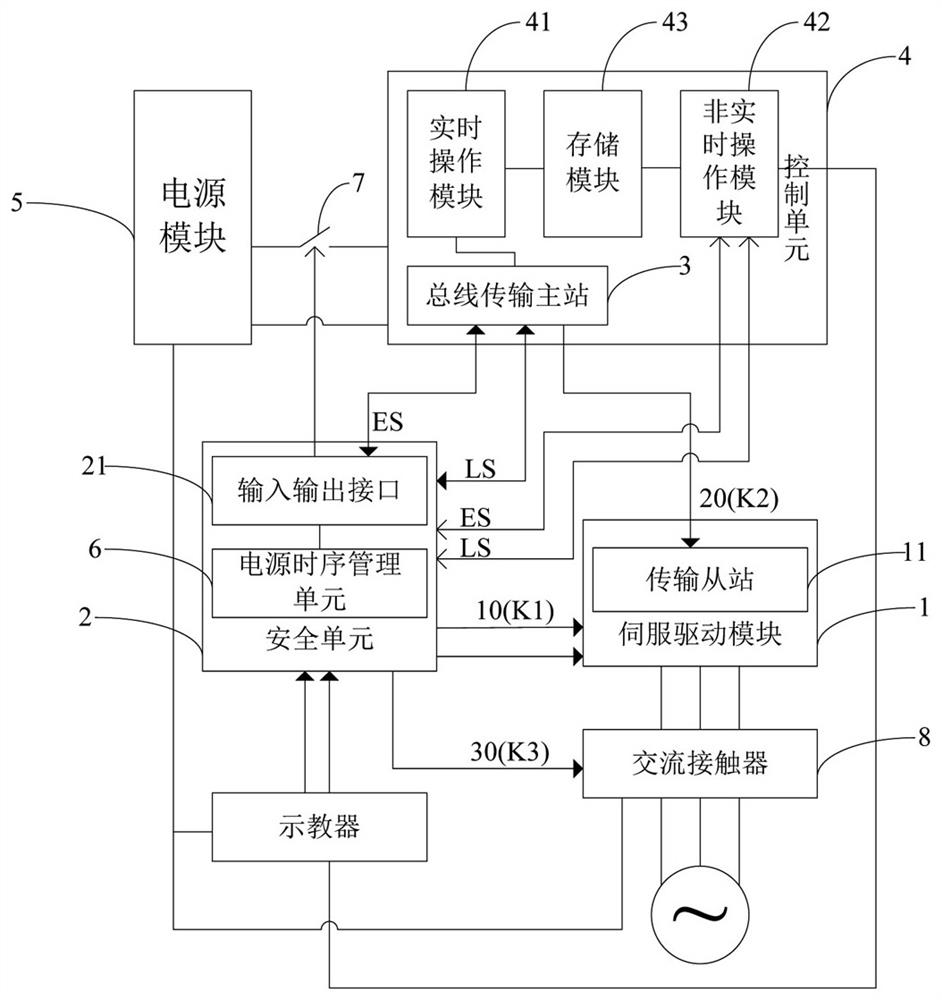

[0042] Such as figure 1As shown, the safety logic control system provided by this embodiment includes a servo drive module 1, a safety unit 2, and a bus transmission master station 3 connected to each other. The safety unit 2 and the bus transmission master station 3 monitor each other, and the safety unit 2 and the servo A first safety loop 10 is established between the drive modules 1 , and a second safety loop 20 is established between the bus transmission master station 3 and the servo drive module 1 . When the safety unit 2 receives an abnormal input signal, detects that the bus transmission master station 3 fails or itself fails, the first safety loop 10 generates a first safety control signal K1 to turn off the output of the servo drive module. At the same time, when the bus transmission master station 3 receives the abnormal input signal output by the safety unit 2, or when it fails or detects that the safety unit 2 fails, a second safety control signal K2 is generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com