Electromagnetic relay structure

A technology of electromagnetic relay and magnetic circuit, applied in the direction of electromagnetic relay, detailed information of electromagnetic relay, relay, etc., can solve the problems that it is difficult to improve the consistency and efficiency of parts, affect the performance of electromagnetic relay, and the structure of moving spring is not stable, etc., to achieve Compact structure, improved air gap and creepage distance, and reduced product volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

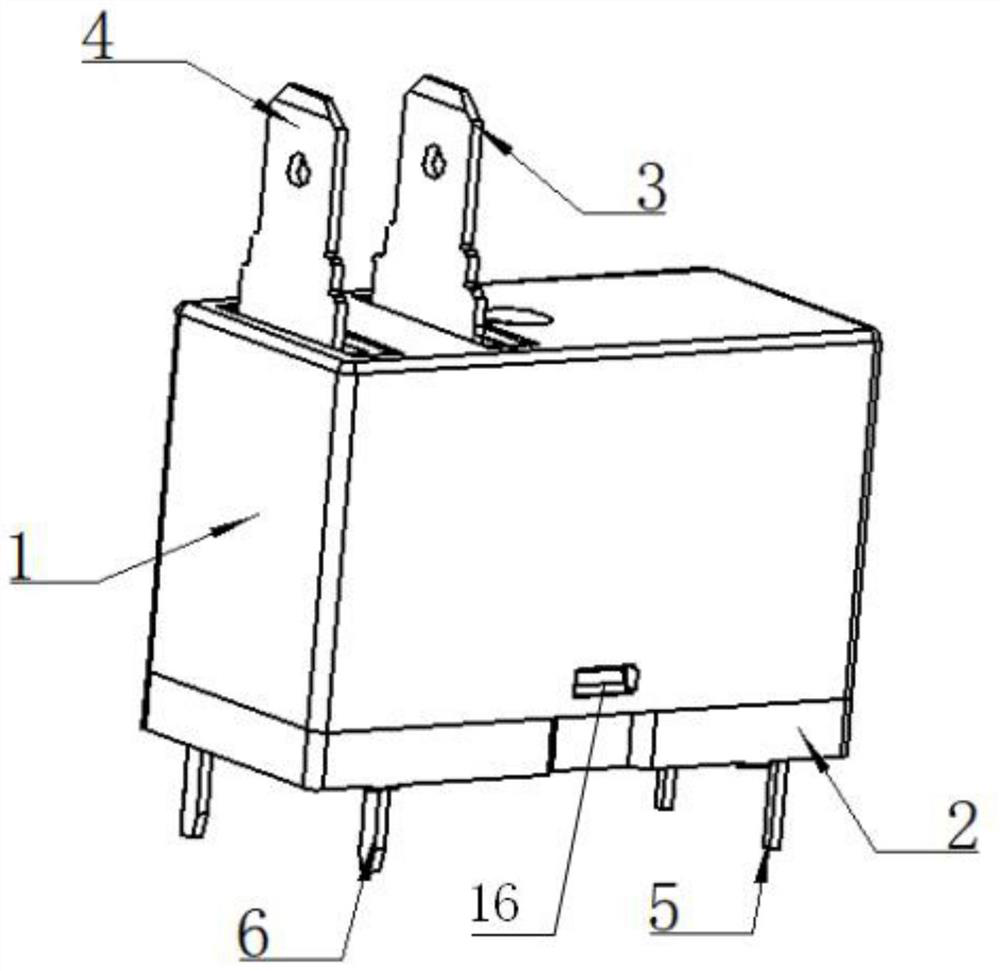

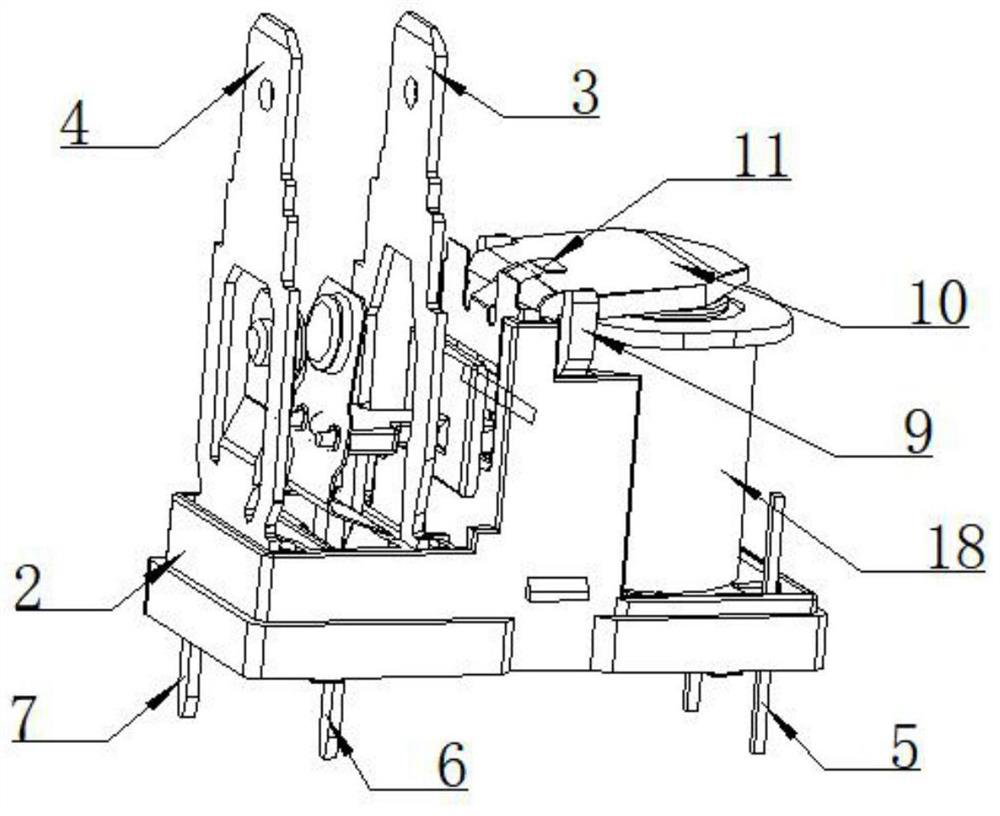

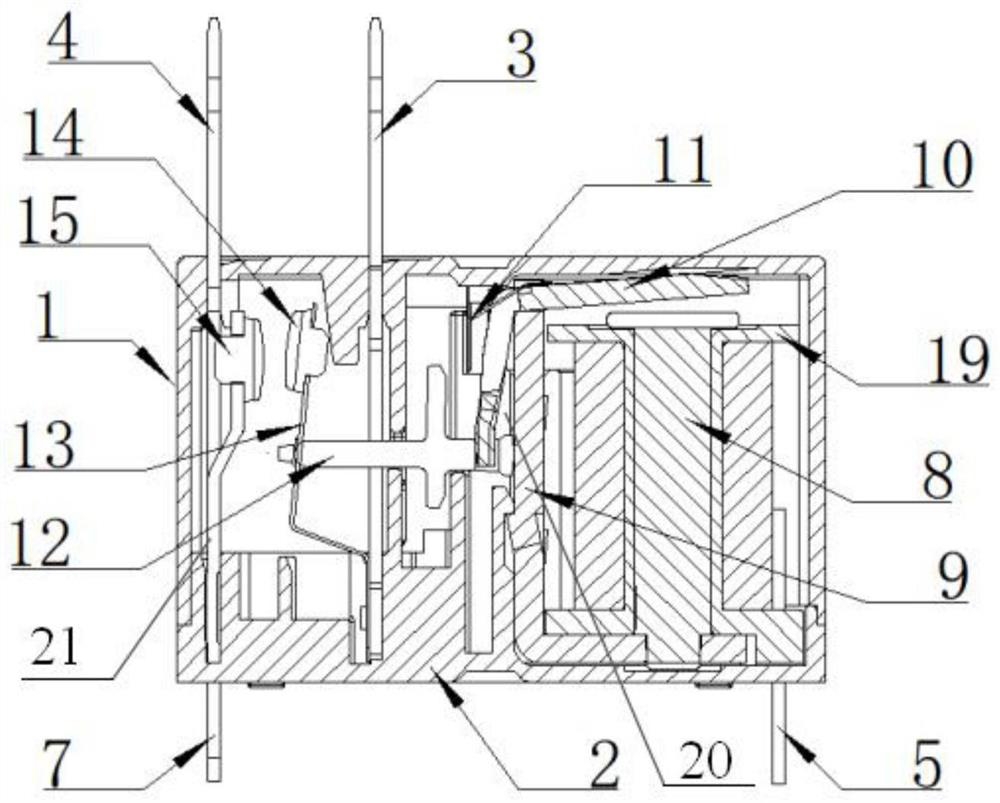

[0034] see figure 1 , figure 2 and image 3 , an electromagnetic relay structure, including a magnetic circuit mechanism and a contact element arranged in a casing 1;

[0035] The magnetic circuit mechanism includes a bobbin 19 arranged on the base 2, the bobbin 19 is longitudinally provided with a first through-slot through the bobbin 19, the first through-slot is provided with an iron core 8, and the bobbin 19 is wound There is a coil 18, and the coil 18 is connected to the terminal 5 of the coil 18 that runs through the base 2; the base 2 is longitudinally provided with a mounting slot 20 for installing the L-shaped yoke 9 and the armature 10; the armature 10 includes a longitudinally inclined section and is connected to it The oblique section, the vertical oblique section is embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com