Cable deicing equipment in field of cable engineering

A cable engineering and cable technology, which is applied in the field of cable deicing equipment, can solve problems such as wasting manpower, and achieve the effects of improving installation efficiency, saving manpower, and having a convenient and simple fixing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

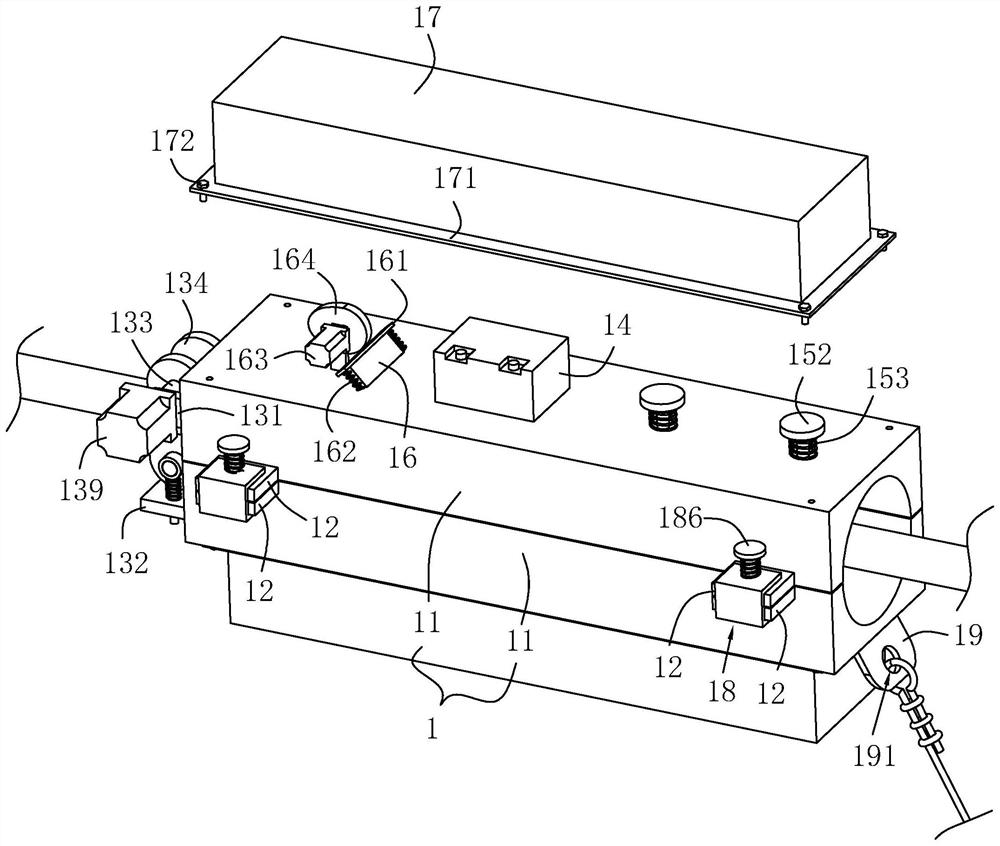

[0036] refer to figure 1 , is a cable deicing device in the field of cable engineering disclosed by the present invention, comprising a moving cylinder 1 for being sleeved on the cable.

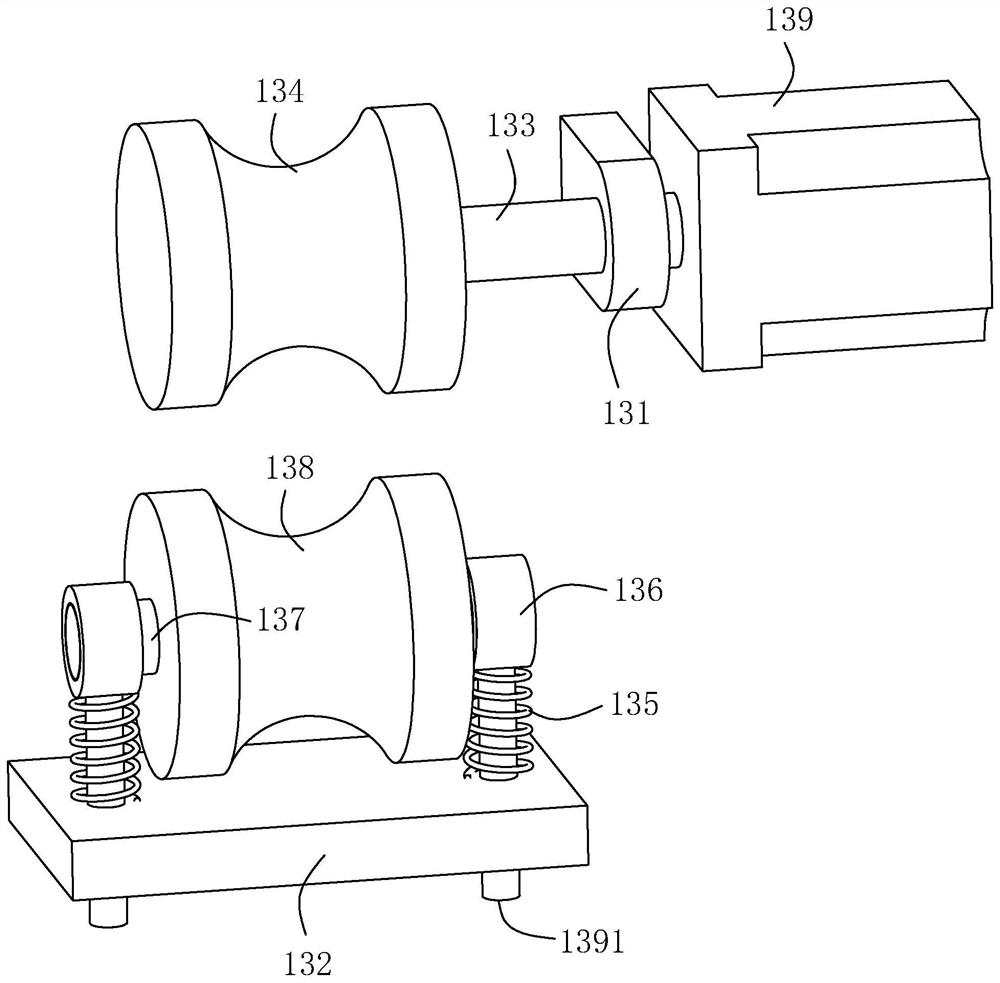

[0037] Such as figure 1 As shown, in order to conveniently set the moving cylinder 1 on the cable, the moving cylinder 1 includes two splicing cylinders 11 which are spliced together, and each side edge of the splicing cylinder 11 is provided with a plurality of connecting plates 12. The connecting plates 12 of the two splicing barrels 11 are parallel to each other and oppositely arranged.

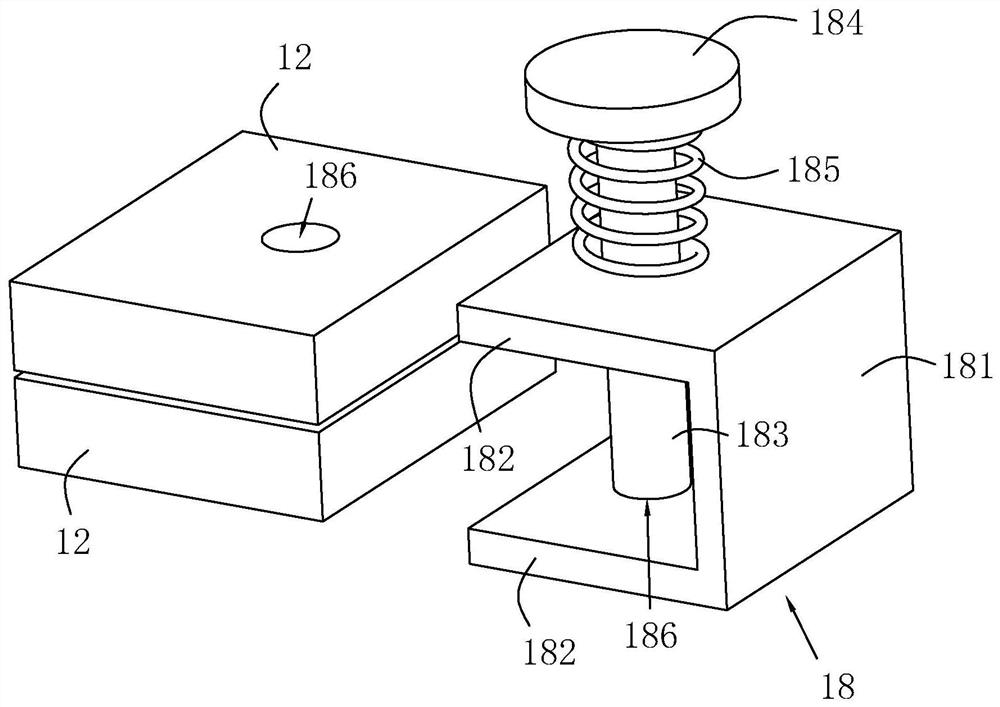

[0038] combine figure 1 and figure 2 , in order to fix the two splicing cylinders 11 to the cable, a fixing member for fixing the two splicing cylinders 11 together is provided on the connecting plate 12 opposite to the two splicing cylinders 11 .

[0039] combine figure 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com