Injection molded screening apparatuses and methods

A technology of screening and screening area, which is applied in the field of screening materials and screening components, can solve the problems of error-prone, unable to withstand high temperature and complexity, unable to withstand compressive loads, etc., to achieve light weight, simple assembly, and eliminate the need Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0238] In some of the figures, like reference numerals refer to like parts.

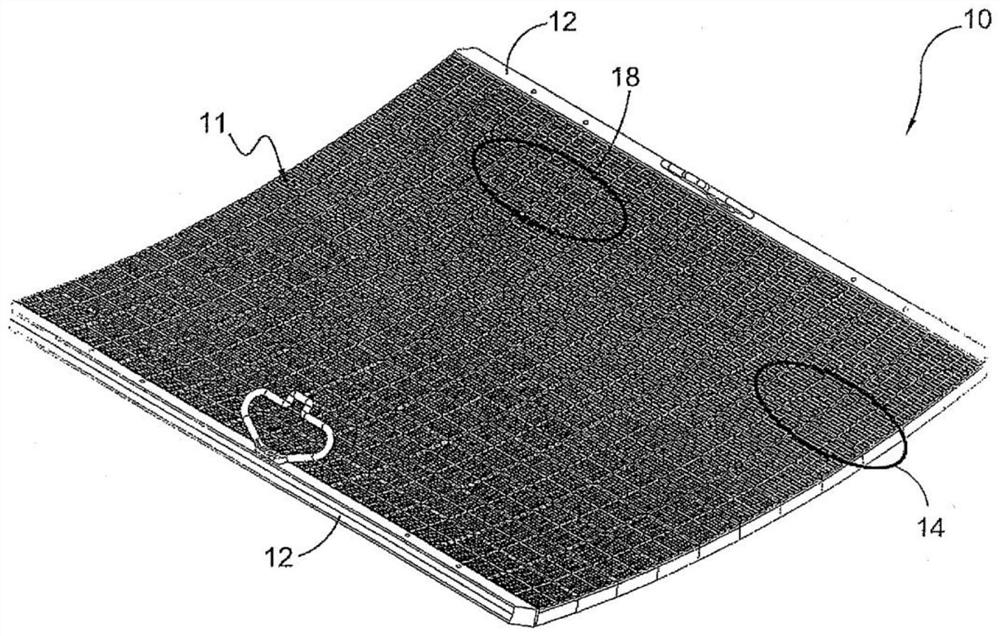

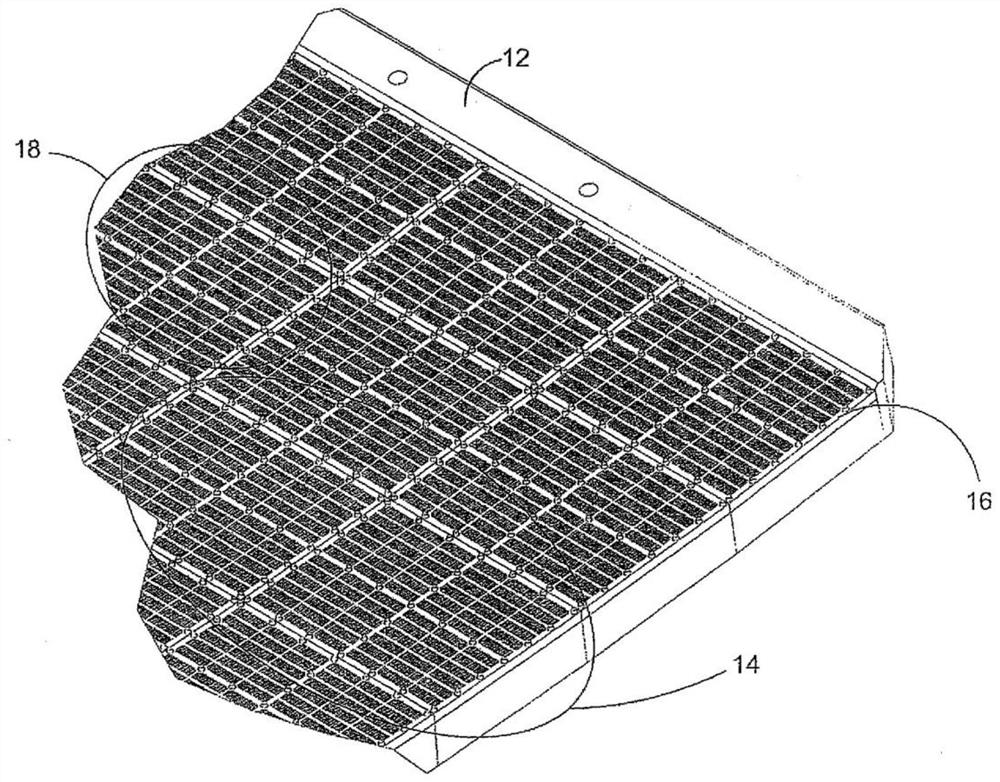

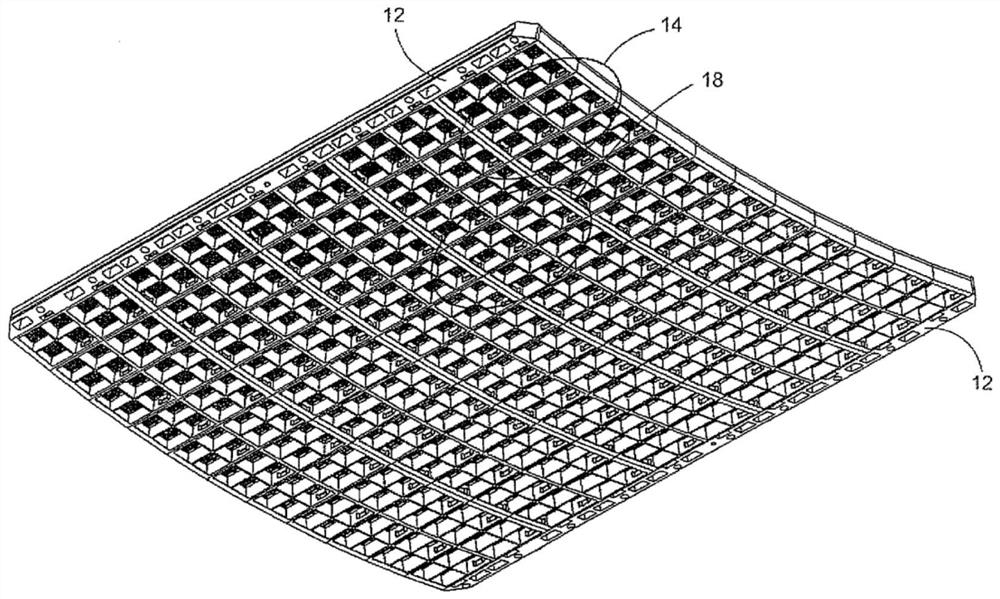

[0239] Embodiments of the present invention provide a screen assembly comprising injection molded screen elements mated with sub-grids. A plurality of sub-grids are fixedly secured to one another to form a vibrating screen assembly having a continuous screening surface configured for use on a vibrating screening machine. The entire screen assembly structure is capable of withstanding severe loading conditions when installed and operated on a vibratory screen machine. Injection molded screen elements offer many benefits in screen assembly manufacturing and vibratory screening applications. In a particular embodiment of the invention, the screen element is injection molded using a thermoplastic material. In some embodiments of the invention, the screen element may have first adhesion means configured to mate with second adhesion means on the sub-grid. The first and second adhering means may comprise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com