Automatic impact needle insertion puncturing device

An automatic needle insertion technology, which is applied in the field of medical equipment, can solve the problems of difficulty in accurately reaching the lesion, easy movement of tissue displacement, and labor-intensive problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

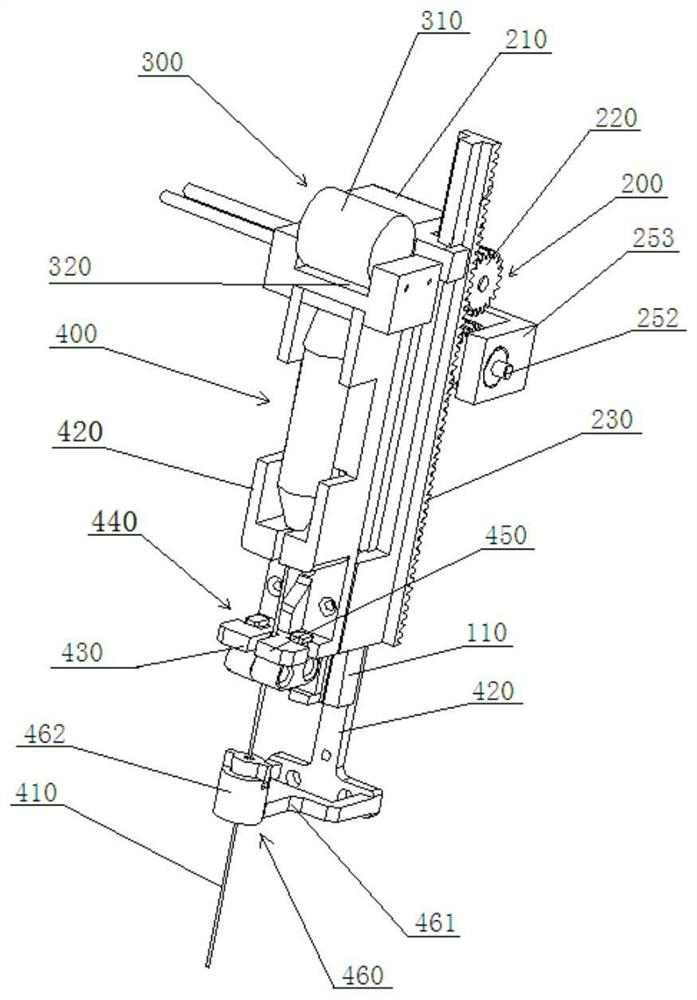

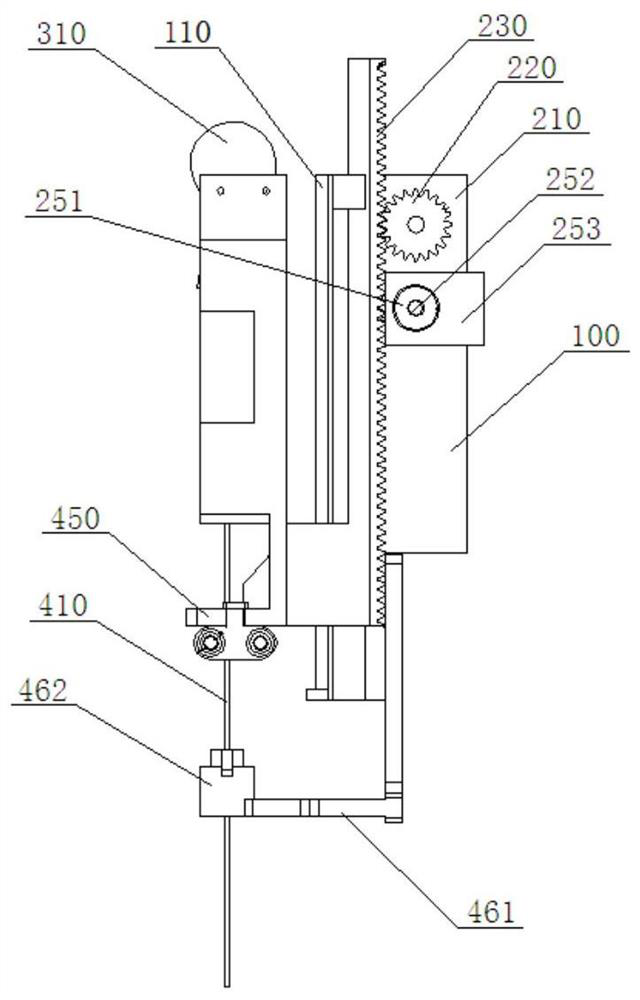

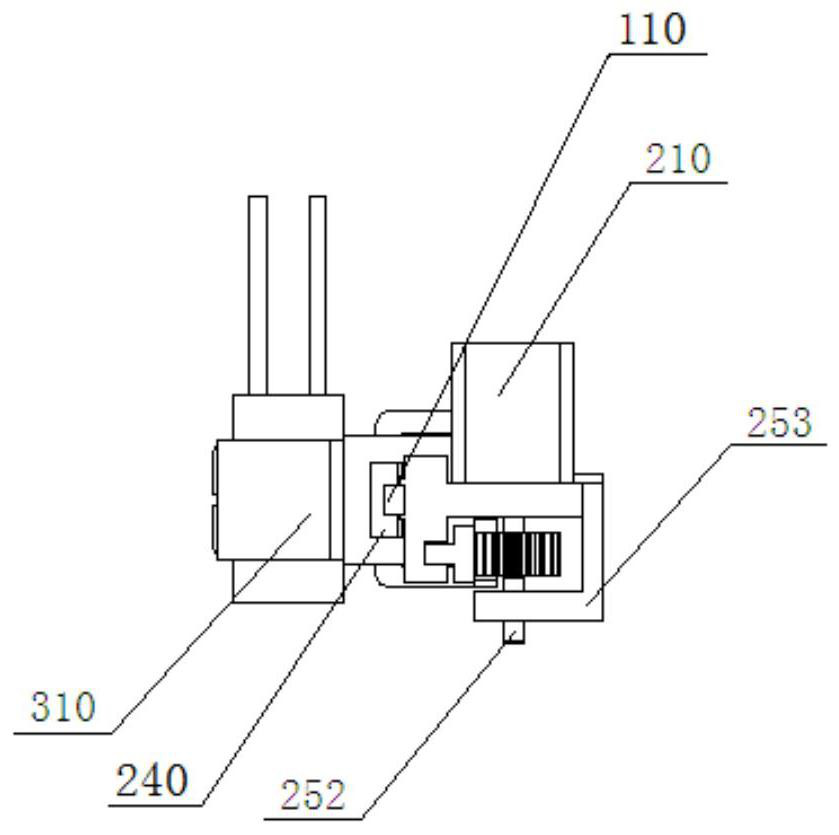

[0023] In this embodiment, mechanical motion and high-pressure air pump impact motion are included. The motor 210 is installed on the base 100, the motor 210 rotates, the driving gear 220 drives the rack 230 to move vertically and linearly, and at the same time, the corresponding driven gear 251 also rotates synchronously.

[0024] The base 100 is equipped with a slide rail 110 , the rack 230 is fixedly connected with the sliding sleeve 240 , and the rack 230 vertically moves up and down in the direction of the slide rail 110 .

[0025] The base 110 is rigidly fixed to the motor 210 and the slide rail 110 respectively, and the motor 210 is mounted with a waist hole design for fine-tuning installation.

[0026] The puncture needle assembly 400 is composed of a clamping needle part 440, a left jaw, and a right jaw, wherein the clamping needle part 440 and the sliding sleeve 240 are fixedly installed, and the left jaw and the right jaw are respectively designed with a semicircula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com