An auxiliary liquid food feeding device

A liquid food, lumen technology, applied in the direction of therapeutic feeding tubes, etc., can solve the problems of difficult to accurately control the pressure and speed of liquid food, high requirements for corrosion resistance of parts, and no inflow and outflow valves, so as to ensure smoothness, Compact structure design, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

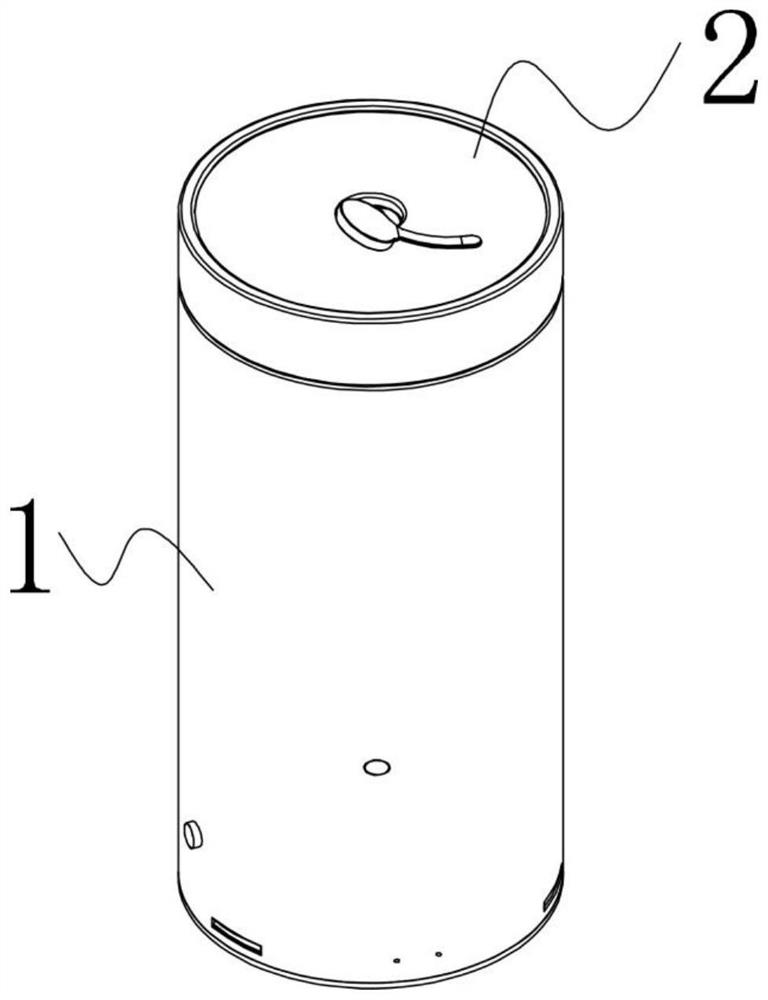

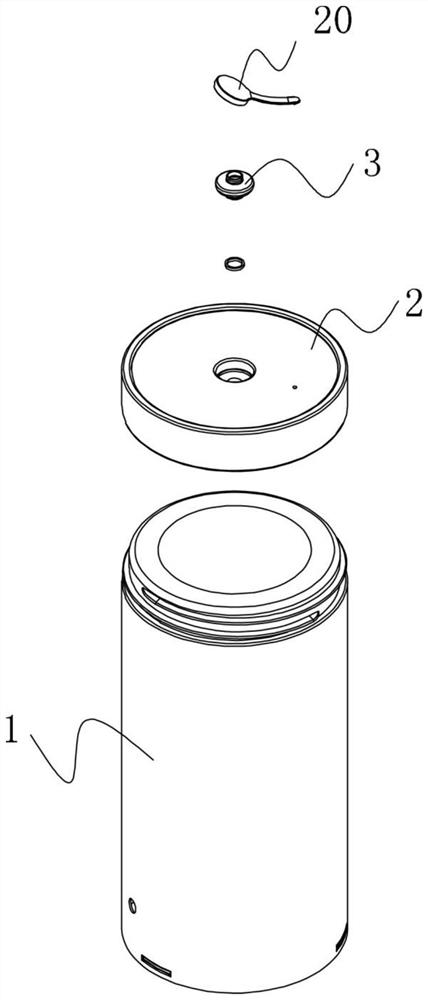

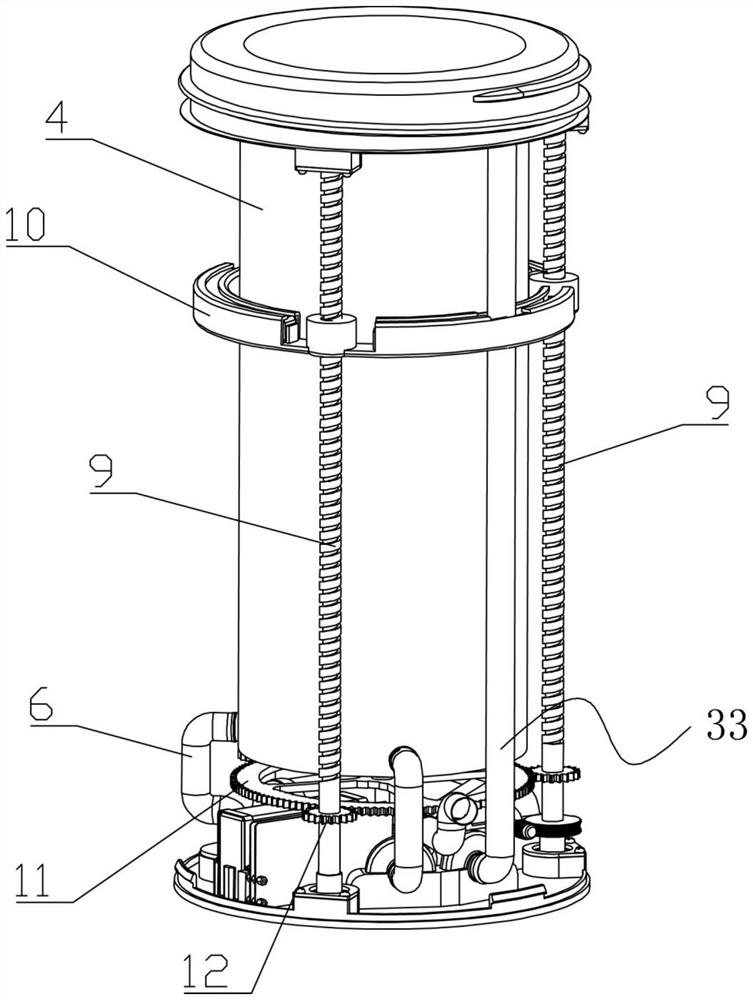

[0047] like Figure 1-Figure 9 As shown, an auxiliary liquid food feeding device of the present invention includes a cup body 1 and a cup cover 2 sealed on the cup body 1. The cup body 1 is provided with a two-way feeding mechanism; the cup cover 2 is provided with a first feeding mechanism. The first feeding hole is provided with a first one-way valve 3 for one-way flow into the cup cover 2; the cup body 1 includes a shell and an inner cavity 4 for storing liquid food, and the top of the shell and the inner cavity 4 is sealed Setting, the bottom of the inner cavity 4 is provided with a second feeding hole, the second feeding hole is connected with a feeding tube 6 through a second one-way valve 5 that flows into the inner cavity 4 in one direction, and the feeding tube 6 passes through the shell; The feeding mechanism includes an inner cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com