Friction stir welding lap joint tool

A friction stir welding and cutting tool technology, which is used in welding equipment, manufacturing tools, non-electric welding equipment, etc., and can solve the problems of insufficient weld metal flow, HOOK defects, and poor heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

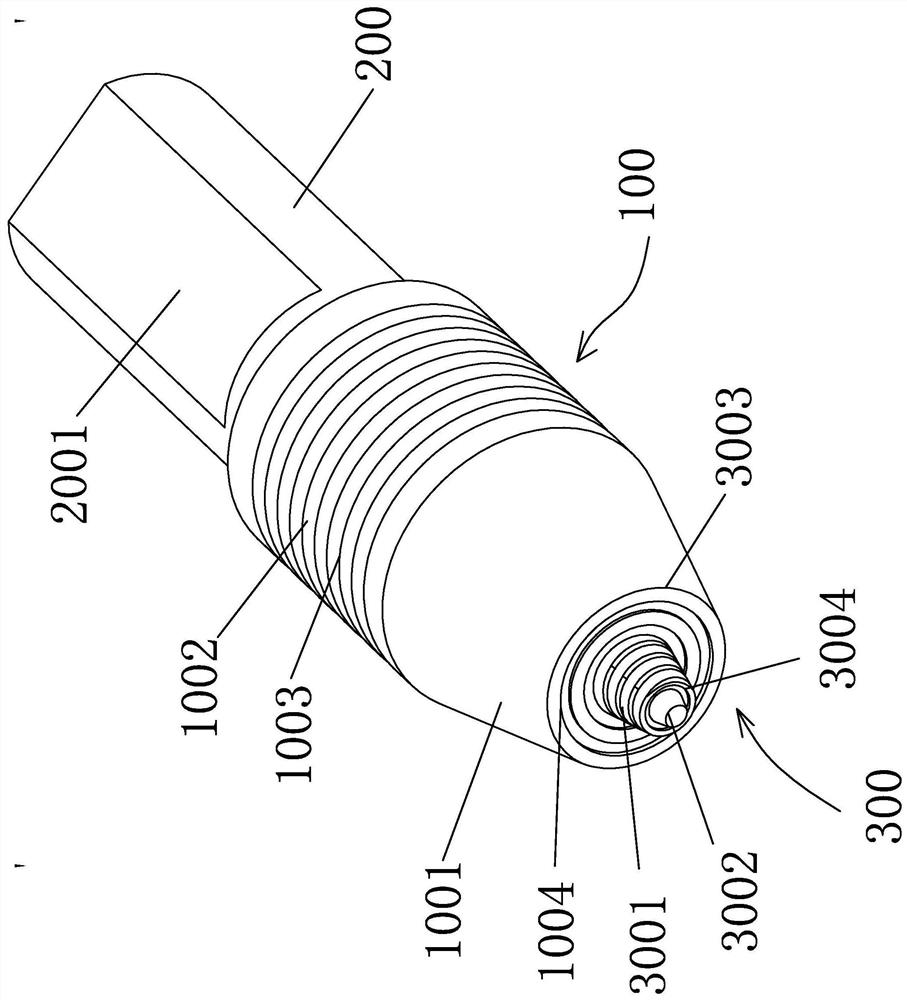

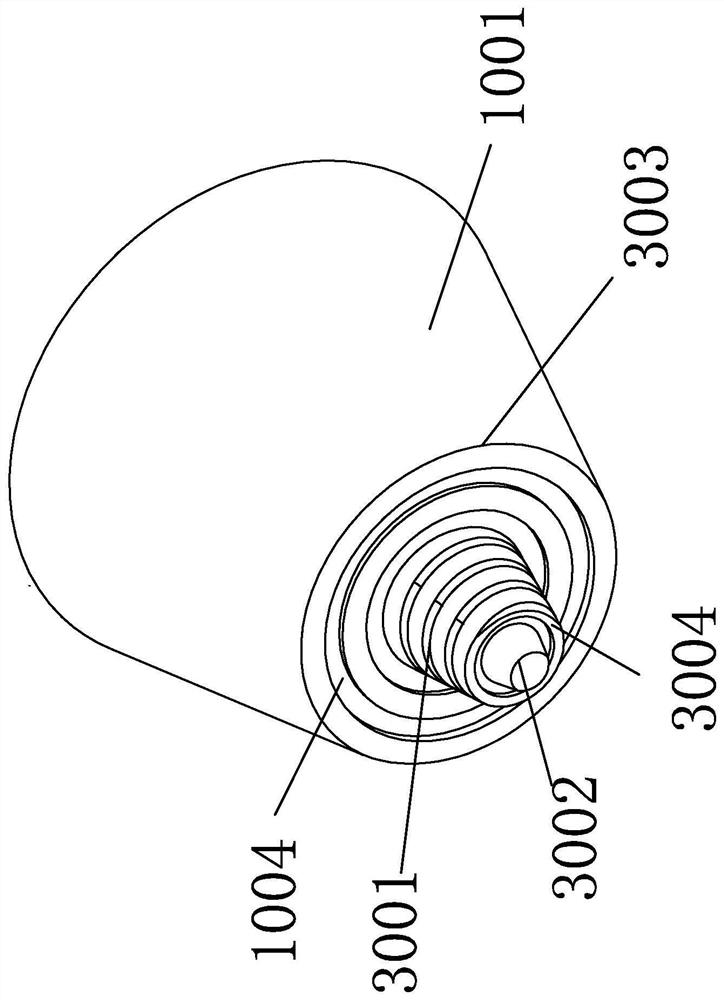

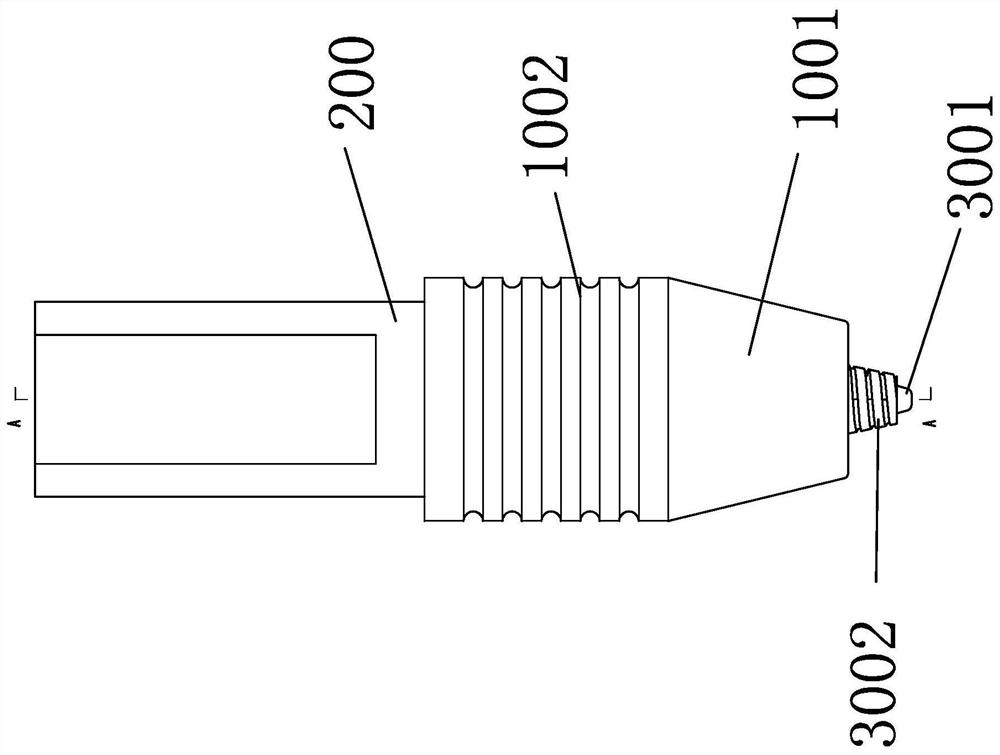

[0022] In the figure, cutter body 100; transition part 1001; heat dissipation part 1002; heat dissipation ring 1003; matching ring 1004; clamping handle 200; positioning groove 2001; working part 300; large stirring needle 3001; small stirring needle 3002; large shoulder 3003; small shoulder 3004; circular convex ring 3005; circular groove 3006; upper plate 400; lower plate 500.

[0023] Such as figure 1 and Figure 5 As shown, the friction stir welding lap tool is used to lap the upper plate 400 and the lower plate 500. The whole tool is processed in one piece, mainly including the tool body 100, the clamping handle 200 and the working part 300. The whole tool is suitable for aluminum The FSW welding of lap joints of al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com