Production method and production facility of waterproof breathable valve

A technology for waterproof and breathable valves and production equipment, which is applied in the field of automation and can solve problems such as easy damage to the breathable membrane and affecting the service life of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0031] A method for producing a waterproof breathable valve, comprising:

[0032] Step 1. Put the breathable membrane into the injection mold that can injection mold the shell of the breather valve;

[0033] Step 2: Injection molding and demoulding to obtain a vent valve housing embedded with a vent membrane;

[0034] Step 3: Assemble the breathable valve shell with the breathable membrane embedded in it and the breathable valve cover to obtain a waterproof breathable valve;

[0035] Step 4: Install a sealing ring on the waterproof and breathable valve.

specific Embodiment 2

[0037] A method for producing a waterproof breathable valve, comprising:

[0038] Step 1. Put the breathable membrane into an injection mold capable of injection molding the shell of the breather valve and the cover of the breather valve;

[0039] Step 2: Injection molding and demoulding to obtain a waterproof and breathable valve embedded with a breathable membrane.

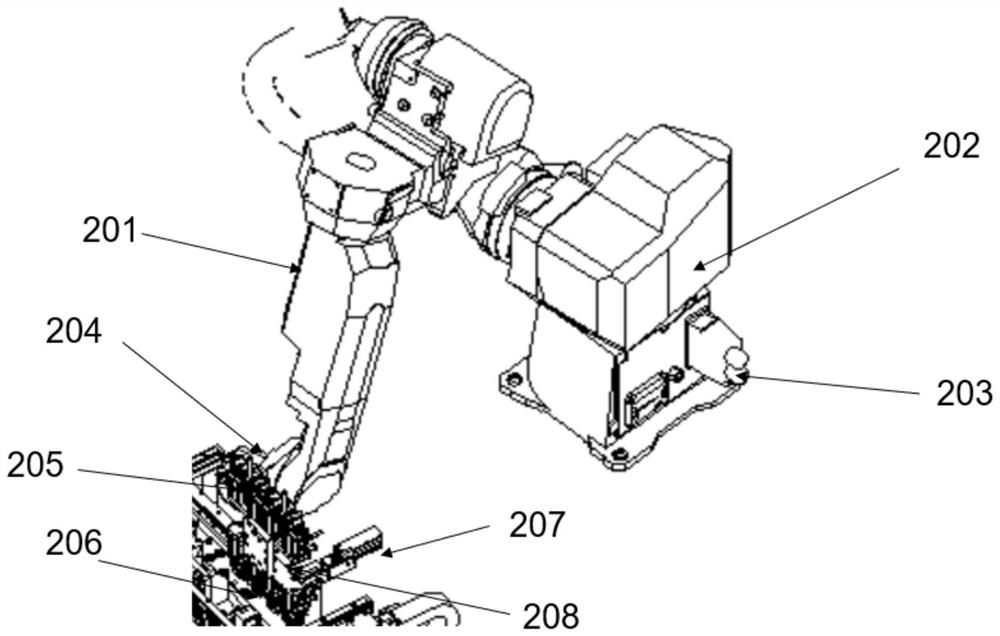

[0040] About production equipment

[0041] About the automatic stripping positioning module of the air-permeable film:

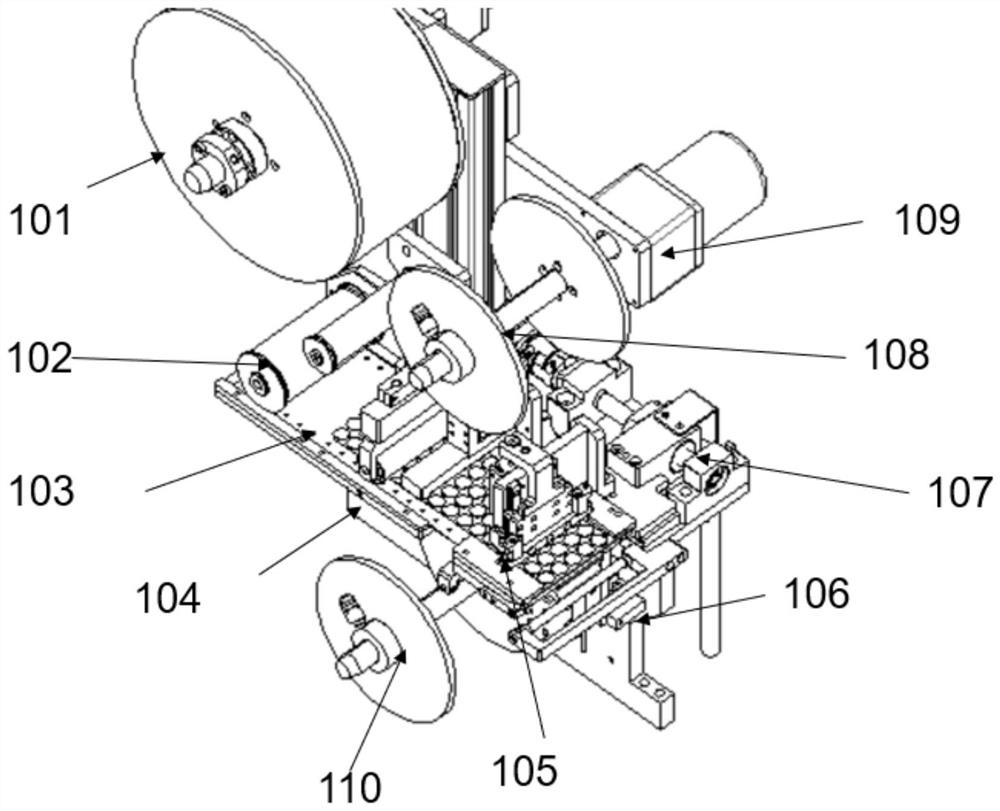

[0042] The breathable membrane automatic peeling positioning module includes a breathable membrane roll support 101, a breathable membrane pressure wheel 102, a breathable membrane positioning column 103, a breathable membrane peeling device 105, a breathable membrane sensing device 106, a transmission device 107, a servo drive motor 109, a breathable membrane Bottom film collection tray 110, when in use, install the breathable membrane coiled material on the breathable membrane coiled mater...

specific Embodiment

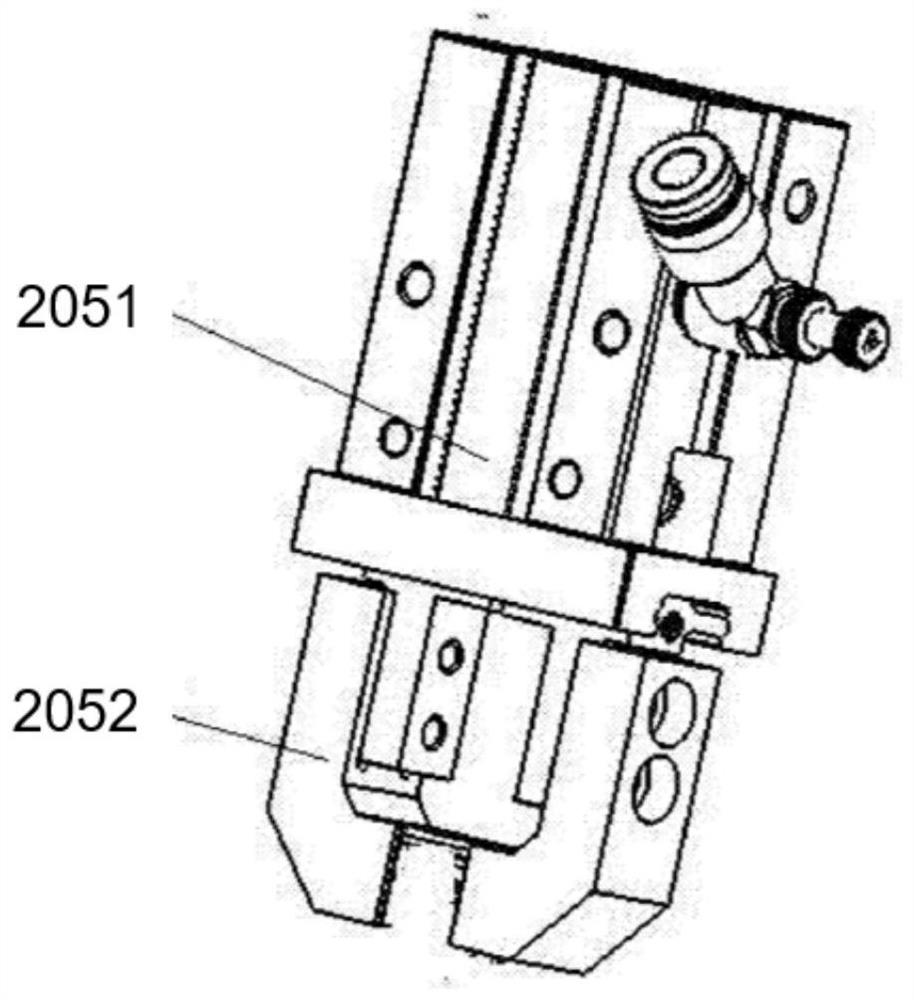

[0044] The breathable membrane automatic peeling positioning module includes a mounting base, and the breathable membrane coil support, the breathable membrane positioning column, the breathable membrane pressure wheel and the breathable membrane peeling device are arranged on the installation base; the breathable membrane coil is installed on the breathable membrane coil support, And press the breathable membrane through the breathable membrane positioning column and the breathable membrane pressure wheel, and the compressed breathable membrane is divided into a breathable membrane and a breathable membrane base film through the breathable membrane stripping device, and the breathable membrane base film is wound on the breathable membrane base film collecting wheel The air-permeable film bottom film collecting wheel is connected with the servo drive motor; the air-permeable film peeling device is also provided with a position sensor of the air-permeable film corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com