Welder control circuit system

A technology for controlling circuits and welding machines, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems that analog circuits cannot adapt to multi-functional operations and complex operations, and achieve diversified data transmission methods and long transmission distances Far, parameter display intuitive and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

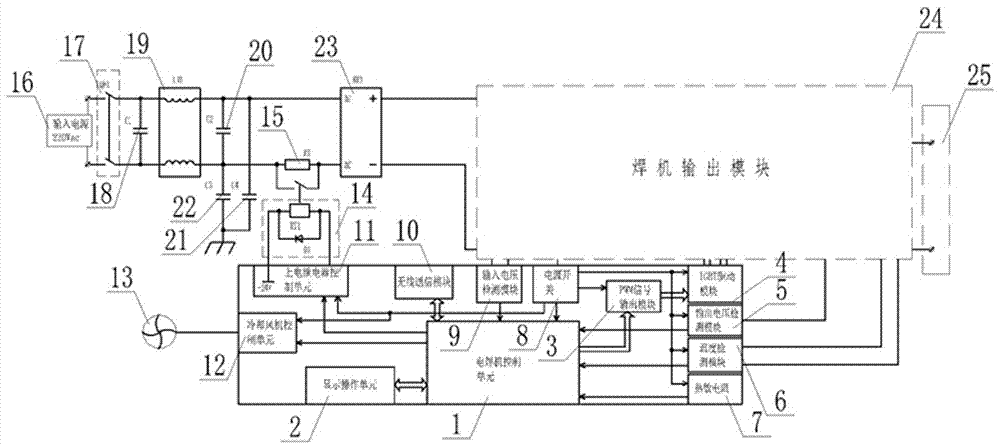

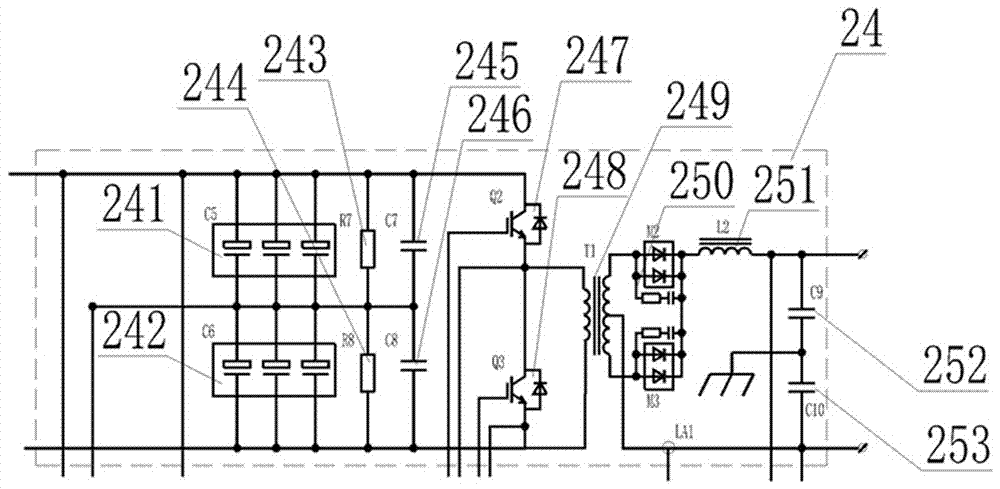

[0022] as attached figure 1 and figure 2 The shown welding machine control circuit system of the present invention includes a welding machine control unit 1, a display operation unit 2, a signal output module 3, an IGBT drive module 4, an output voltage detection module 5, a temperature detection module 6, a thermal Sensitive resistor 7, power switch 8, input voltage detection module 9, wireless communication module 10, power-on relay control unit 11, cooling fan control unit 12, fan 13, power-on relay 14, power-on resistor 15, input power supply 16, input Switch 17, input capacitor 18, filter 19, output capacitor 20, first ground capacitor 21, second ground capacitor 22, rectifier module 23, welder output module 24 and welder output 25, the electric welder controls The unit 1 is electrically connected with a display operation unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com