Error proof inspection device after failure of gasket vibration plate

A technology of inspection device and vibrating plate, which can be used in transportation and packaging, conveyor objects, etc., and can solve problems such as gasket scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

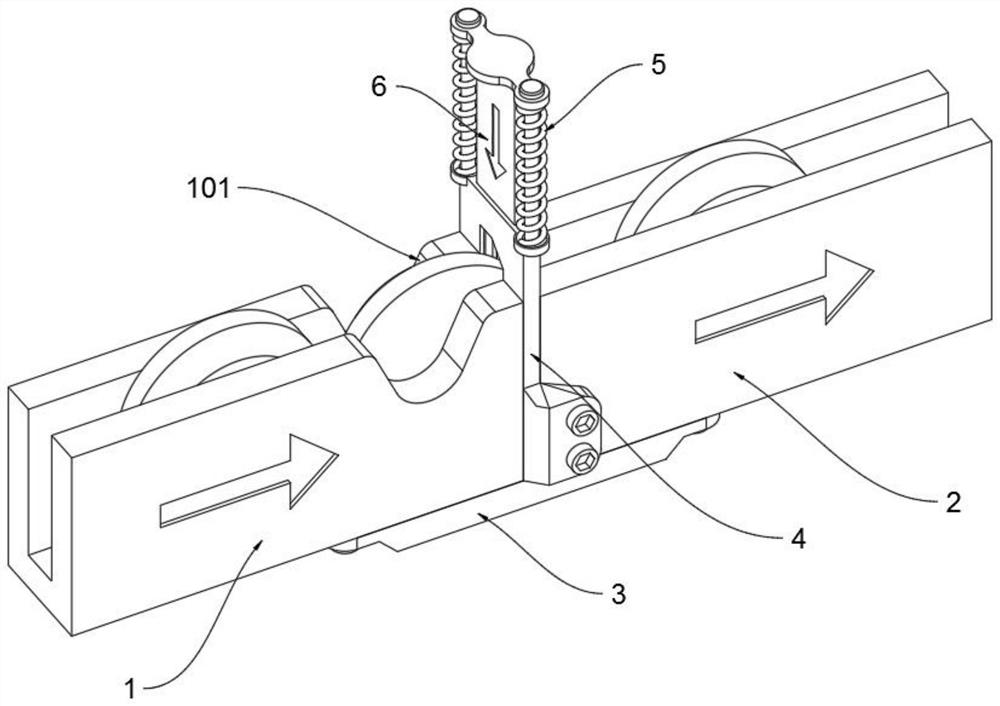

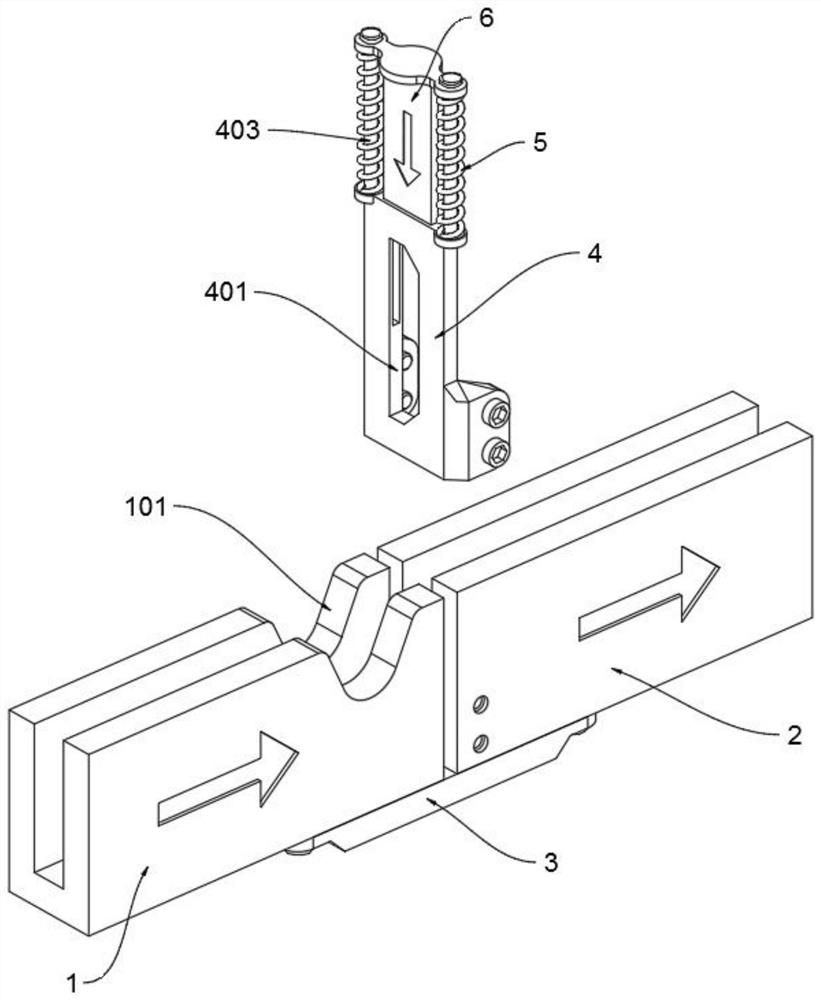

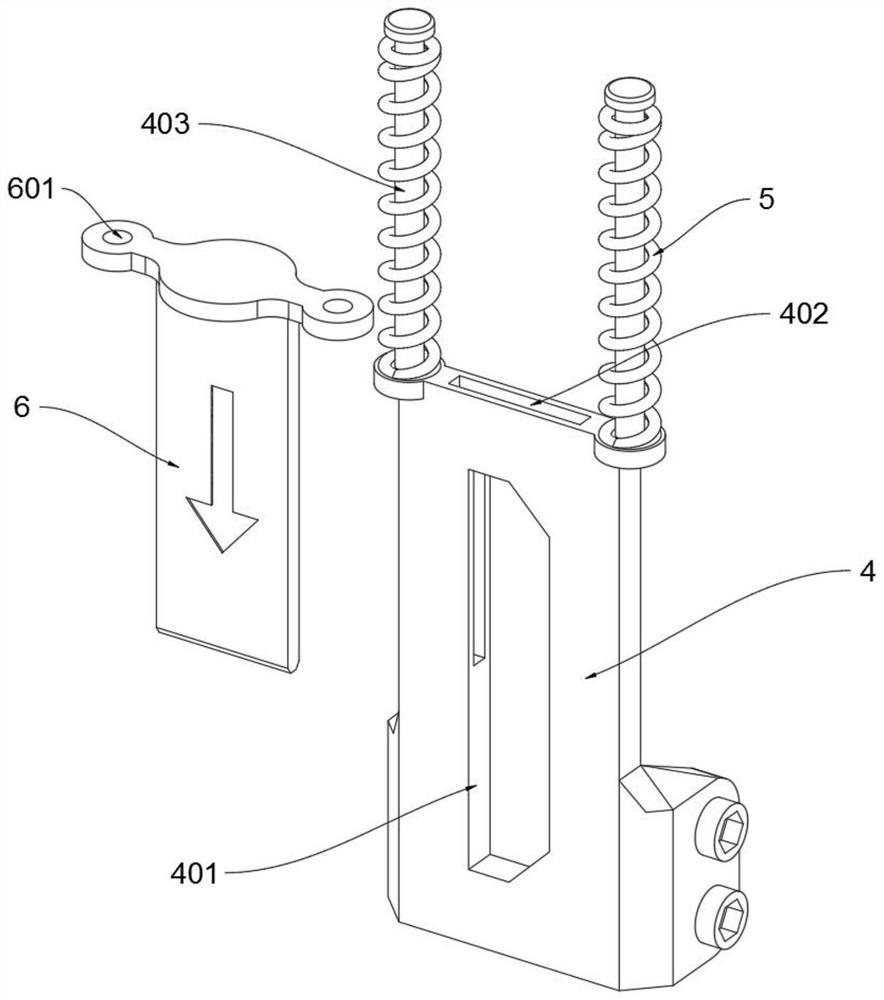

[0021] as attached figure 1 to attach image 3 Shown:

[0022] The present invention provides an error-proof inspection device after the gasket vibrating plate fails, which includes a feed guide rail 1, an error-proof baffle plate 4 and an inserting plate 6; the tops of the left and right ends of the feed guide rail 1 are respectively provided with a pick-up gap 101, And the rear end of the bottom of the feeding guide rail 1 is connected to the front end of the connecting base plate 3 through bolts, and the rear end of the discharging guide rail 2 is connected to the rear end of the connecting base plate 3 through bolts; 2. In the butt joint gap, a return spring 5 is respectively connected to the left and right ends of the top of the error prevention baffle 4;

[0023] Wherein, the front end of the error prevention baffle 4 is connected with the feed guide rail 1, the rear end of the error prevention baffle 4 is connected with the discharge guide rail 2, and the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com