Dust falling machine for hydraulic engineering construction site

A water conservancy project, dust machine technology, applied in the use of liquid separation agent, road surface cleaning, separation of dispersed particles, etc., can solve the problems of single function, time-consuming and labor-intensive, and difficult work for staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

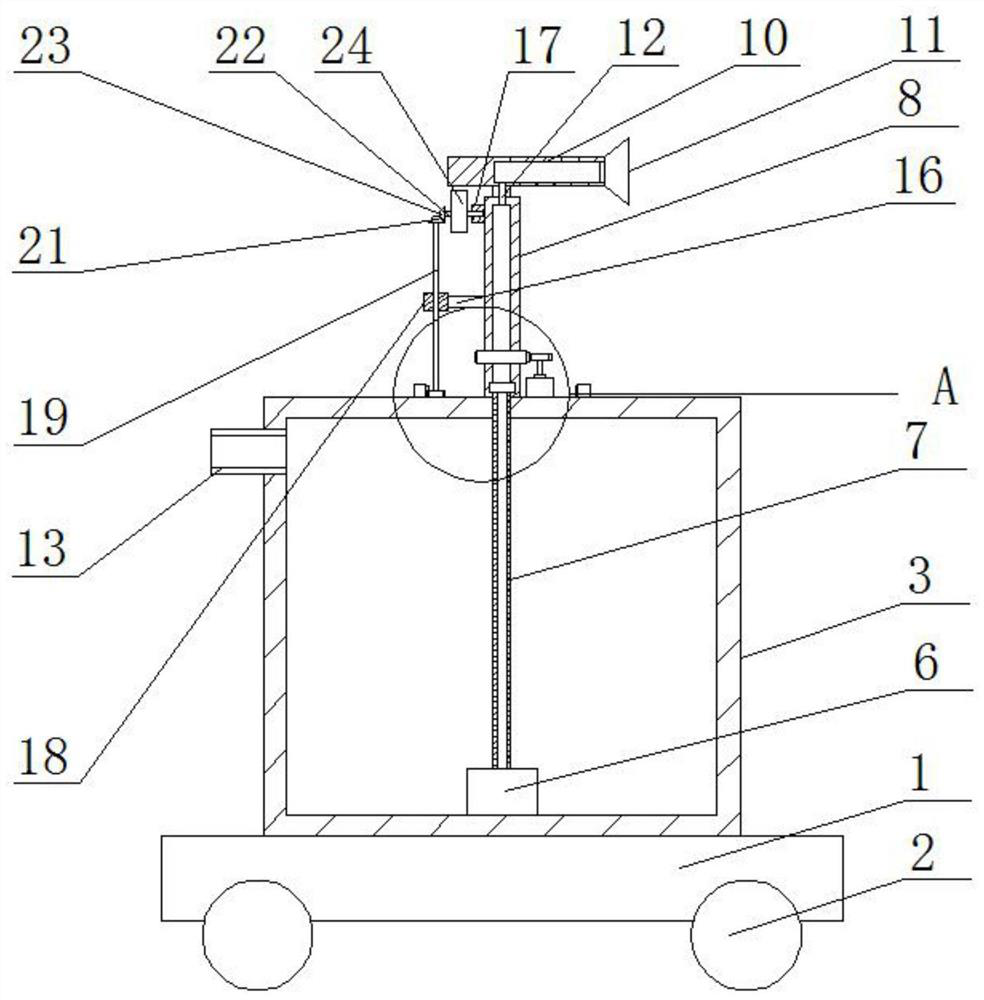

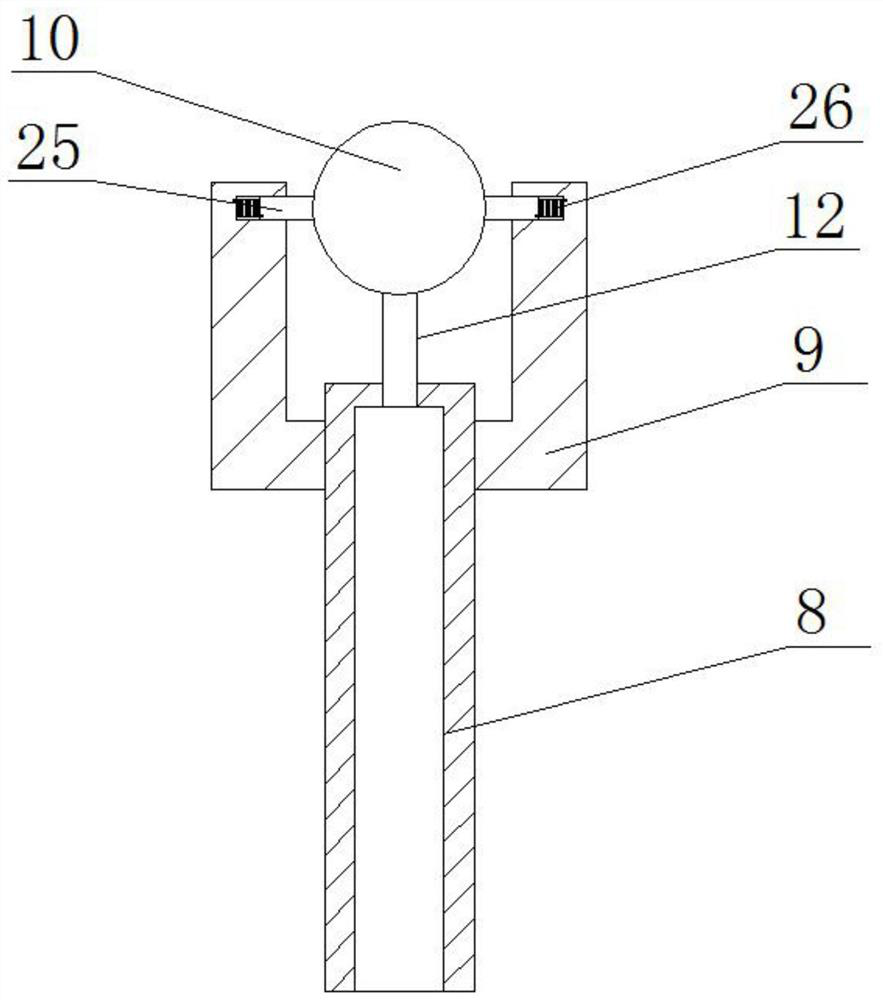

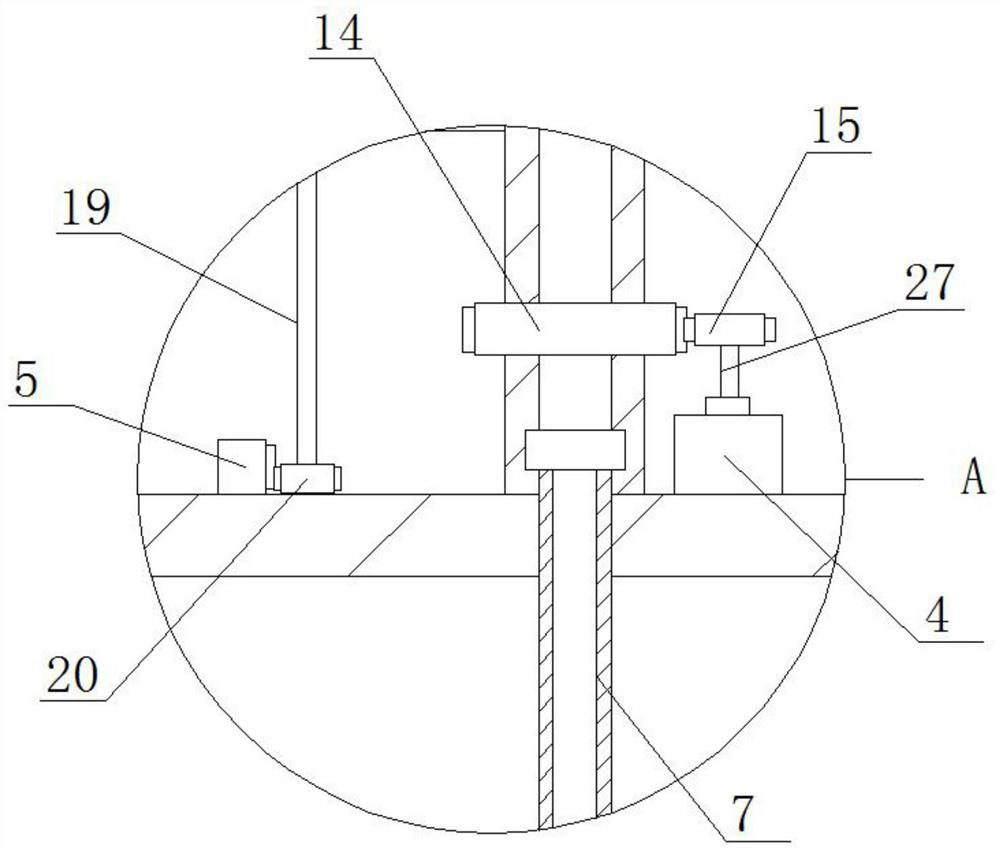

[0021] refer to Figure 1-3 , a water conservancy project construction ground dust suppressor, comprising a base plate 1, four universal wheels 2 are mounted on the bottom of the base plate 1, and the top of the base plate 1 is fixedly connected with a housing 3, and the top of the housing 3 is fixedly installed with a motor 4. The ring gear 5 is fixedly connected to the top of the housing 3, and the water pump 6 is fixedly installed on the inner wall of the bottom of the housing 3. The water outlet of the water pump 6 is connected to one end of the first water pipe 7, and the other end of the first water pipe 7 extends One end of the second water pipe 8 is rotatably sleeved to the outside of the housing 3, one end of two support rods 9 is fixedly connected to the outer side of the second water pipe 8, and the other end of the two support rods 9 is rotatably connected to the same pipe body 10. One end of the pipe body 10 is provided with a nozzle 11, the top of the second wate...

Embodiment 2

[0027] refer to Figure 1-3 , a water conservancy project construction ground dust collector, including a bottom plate 1, four universal wheels 2 are installed on the bottom of the bottom plate 1, and the top of the bottom plate 1 is fixedly connected with a shell 3 by welding, and the top of the shell 3 is connected by bolts The motor 4 is fixedly installed, the top of the housing 3 is fixedly connected with the ring gear 5 by welding, the bottom inner wall of the housing 3 is fixed with a water pump 6 through bolts, and the water outlet of the water pump 6 is connected to one end of the first water pipe 7. The other end of the first water pipe 7 extends to the outside of the housing 3 and is sleeved with one end of the second water pipe 8 . The outer side of the second water pipe 8 is fixedly connected with one end of two support rods 9 by welding. The two support rods 9 The other end of the second water pipe 8 is rotatably connected to the same pipe body 10, one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com