A kind of scramjet combustor flow direction linear plasma igniter and ignition method

A technology of plasma and scram stamping, which is applied in the direction of plasma, machine/engine, gas turbine device, etc., can solve the problems of lack of reliable repeated ignition methods, meet the needs of repeated ignition, improve ignition capacity, and have strong ignition capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

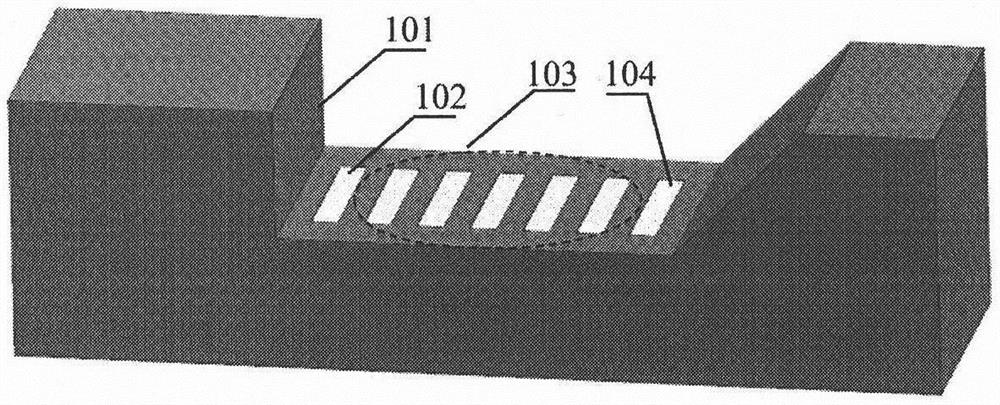

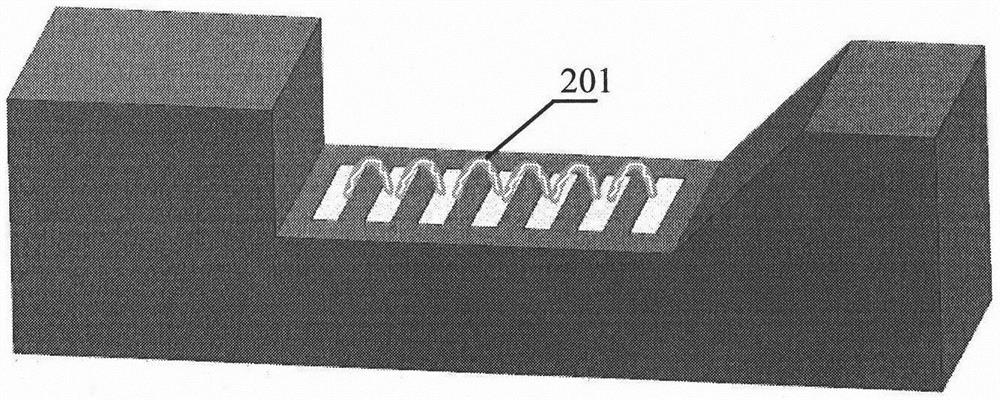

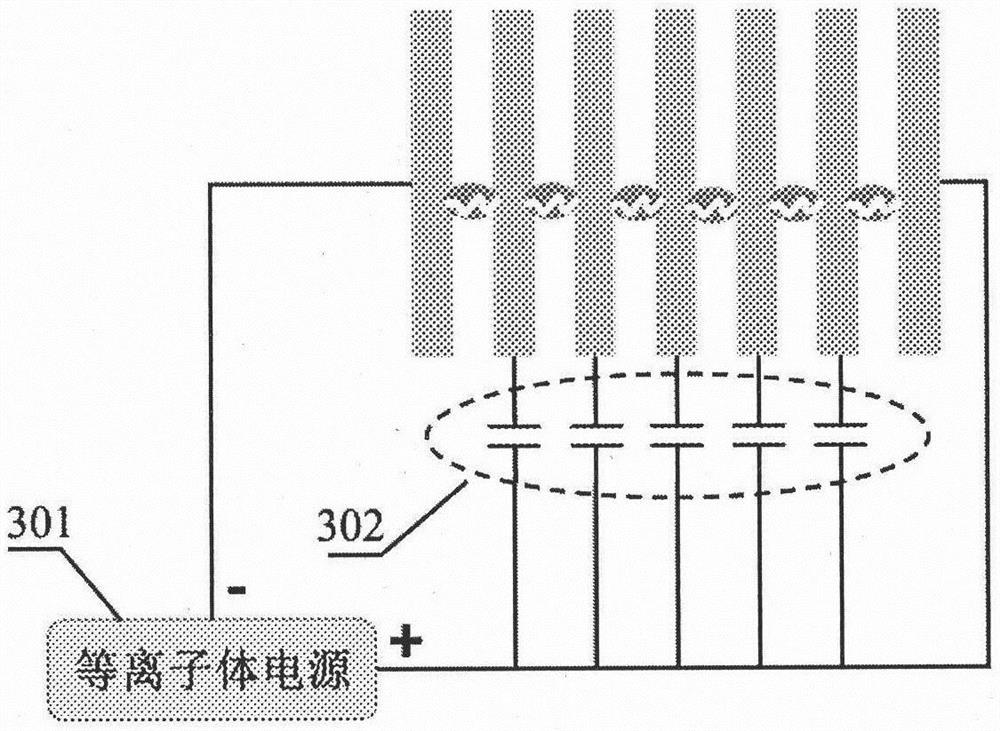

[0048] In a specific embodiment of the present invention, the insulator 101 is sintered from high temperature resistant alumina ceramics, the depth of the cavity is 15mm, the length of the bottom of the cavity is 100mm, and the inclination angle of the inclined wall behind the cavity is 45°. The discharge cathode 102, the discharge anode 104, and the discharge connection electrode 103 are processed from high-temperature-resistant metal materials, preferably nickel-based high-temperature alloys. The discharge cathode 102 is composed of a rectangular single metal strip, with an electrode length of 60mm and a width of 10mm. The discharge anode 104 is composed of a rectangular single metal strip with a length of 60 mm and a width of 10 mm. It is installed in the central area of the back of the bottom of the concave cavity at a distance of 10 mm from the rear end and is connected to the anode of the plasma power supply 301 . The discharge connection electrode 103 is composed of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com