A joint calibration method for laser radar and millimeter wave radar

A millimeter wave radar and lidar technology, applied in radio wave measurement systems, instruments, etc., can solve problems such as being unsuitable for large-scale deployment or mass production, reducing calibration efficiency, and unstable effects, achieving automatic high-precision calibration, Improve the calibration efficiency and eliminate the effect of human factor interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

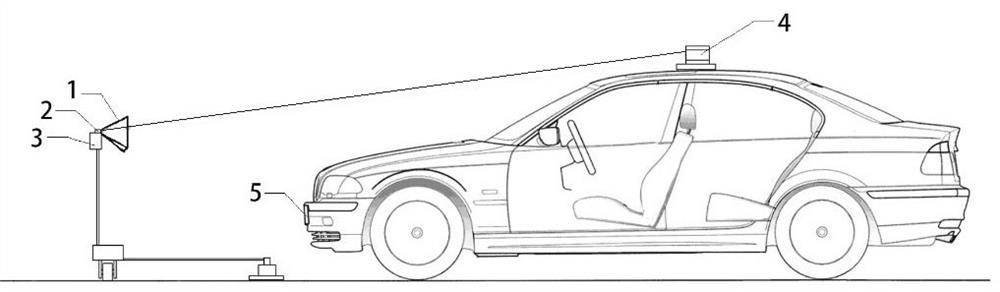

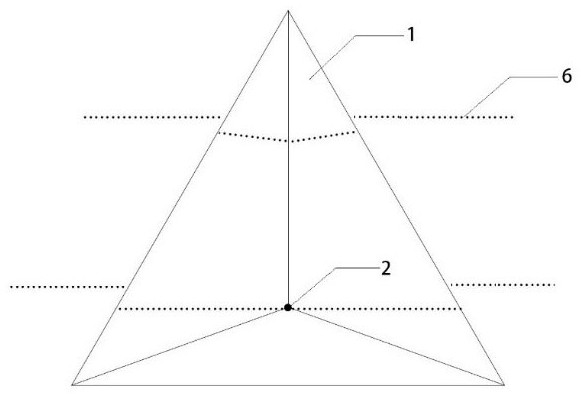

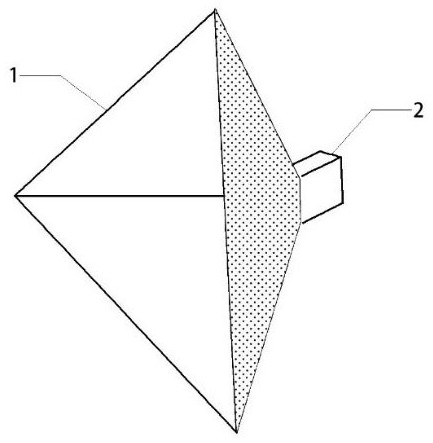

[0021] In this example, if Figure 1-3 As shown, the laser radar 4 and the millimeter-wave radar 5 are fixedly installed at predetermined positions of the electric vehicle, and the relative position between them is fixed, and a corner reflector 1 that can move vertically in space is installed within the sensing range of the millimeter-wave radar 5 , the photosensitive unit 2 for receiving the infrared light 6 emitted by the laser radar 5 is installed at the apex of the corner reflector 1 .

[0022] Among them, the corner reflector 1 can form a strong reflection point within the sensing range of the 24GHz or 77GHz millimeter-wave radar. The corner reflector specification needs to be greater than 0db and less than 20db, and it is best to use a 10db corner reflector. The photosensitive unit 2 can receive the infrared light 6 emitted by the laser radar 4 , such as 905nm or 1550nm. The photosensitive unit can be a point photosensitive unit, a line photosensitive unit or an area ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com