A kind of sic MPS diode device and preparation method thereof

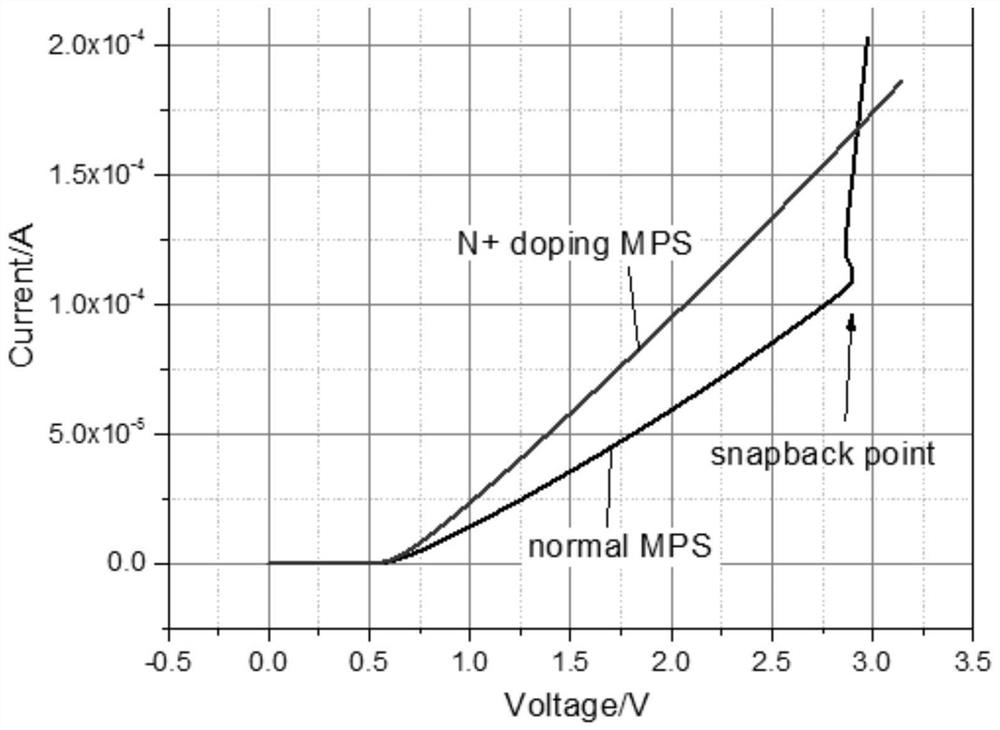

A diode and device technology, applied in the field of SiCMPS diode devices and their preparation, can solve the problems of forward current rebound, device forward function degradation, etc., and achieves the improvement of surge capability, suppression of rapid return of voltage drop, and improvement of injection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above-mentioned SiC MPS diode device comprises the following steps:

[0033] S1: An N- epitaxial layer 4 is formed by epitaxial growth on the N+ substrate 5; the overall structure forming the N- epitaxial layer is usually called an epitaxial wafer;

[0034] S2: Preparation of SiO on N-epitaxial layer 4 2 The mask layer is formed with a mask pattern by a photolithography process, and an N+ implantation region 3 is formed by means of N ion implantation;

[0035] S3: cleaning off the implantation mask layer, forming a new mask layer on the surface, forming a mask pattern by photolithography, and forming a P+ implantation region 2 by means of Al ion implantation;

[0036] S4: cleaning off the implanted mask layer, forming a new mask layer on the surface, forming a mask pattern by photolithography, and then forming a trench structure 7 by ICP etching;

[0037] S5: Protect the surface of the epitaxial layer with a carbon film, activate the impl...

Embodiment 1

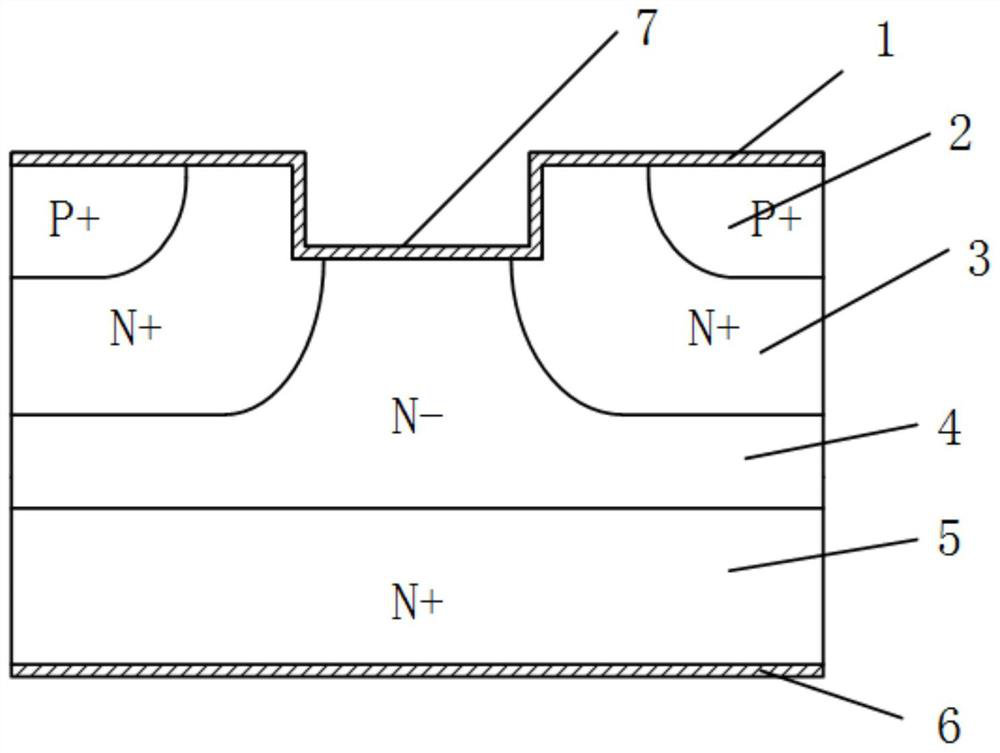

[0043] figure 1 A schematic cross-sectional view of a trench type SiCMPS diode device structure that has carried out N+ implantation for the present invention, combined below figure 1 Describe in detail the apparatus of the present invention;

[0044] A trench-type SiC MPS diode device structure with N+ implantation: including an N+ substrate 5 with a doping concentration of 5×10 18 atom / cm 3 Made of SiC material with a thickness of 350 μm, the lightly doped N- epitaxial layer 4 is located on the N+ substrate 5; the cathode 6 is located below the substrate; the surface of the N- epitaxial layer 4 is provided with a trench structure 7; the P+ implantation region 2 is located The surface of the N- epitaxial layer 4 around the trench structure 7; the N+ implantation region 3 is located around the P+ implantation region 2, and the anode covers the entire surface of the P+ implantation region 2 and the surface of the trench structure 7.

[0045] The process steps are as follows:...

Embodiment 2

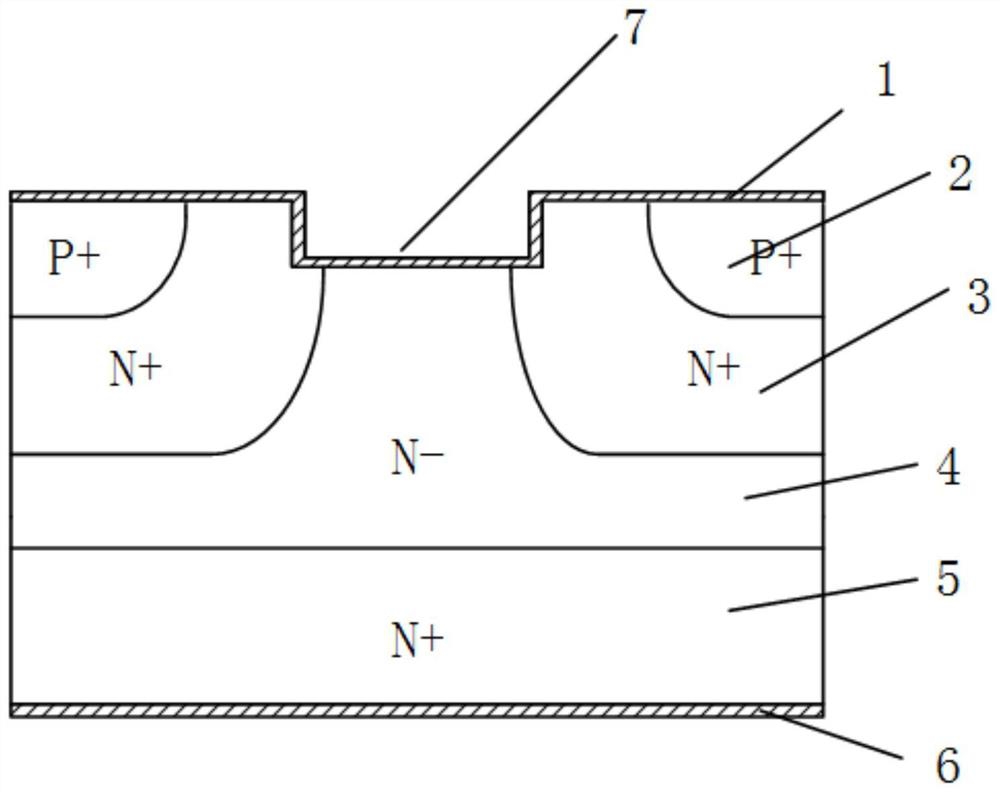

[0055] figure 2 It is a schematic cross-sectional view of the structure of a trench type SiC MPS diode device with N+ implantation in the present invention, combined below figure 2 Describe in detail the apparatus of the present invention;

[0056] A trench type SiC MPS diode device structure with N+ implantation: including N+ substrate 5, with a doping concentration of 5×10 18 atom / cm 3 Made of SiC material with a thickness of 350 μm; the lightly doped N- epitaxial layer 4 is located on the N+ substrate 5; the cathode 6 is located under the substrate; the surface of the N- epitaxial layer 4 is provided with a trench structure 7; the P+ implantation region 2 is located The surface of the N- epitaxial layer 4 around the trench structure 7; the N+ implantation region 3 is located around the P+ implantation region 2, and the anode covers the entire surface of the P+ implantation region 2 and the surface of the trench structure 7.

[0057] The process steps are as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com