Edge folding equipment for bottom plate of refrigerating chamber

The technology of a bottom plate and equipment is applied in the field of folding equipment for the bottom plate of a refrigerated compartment, and can solve the problems of increased labor cost, low processing efficiency, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

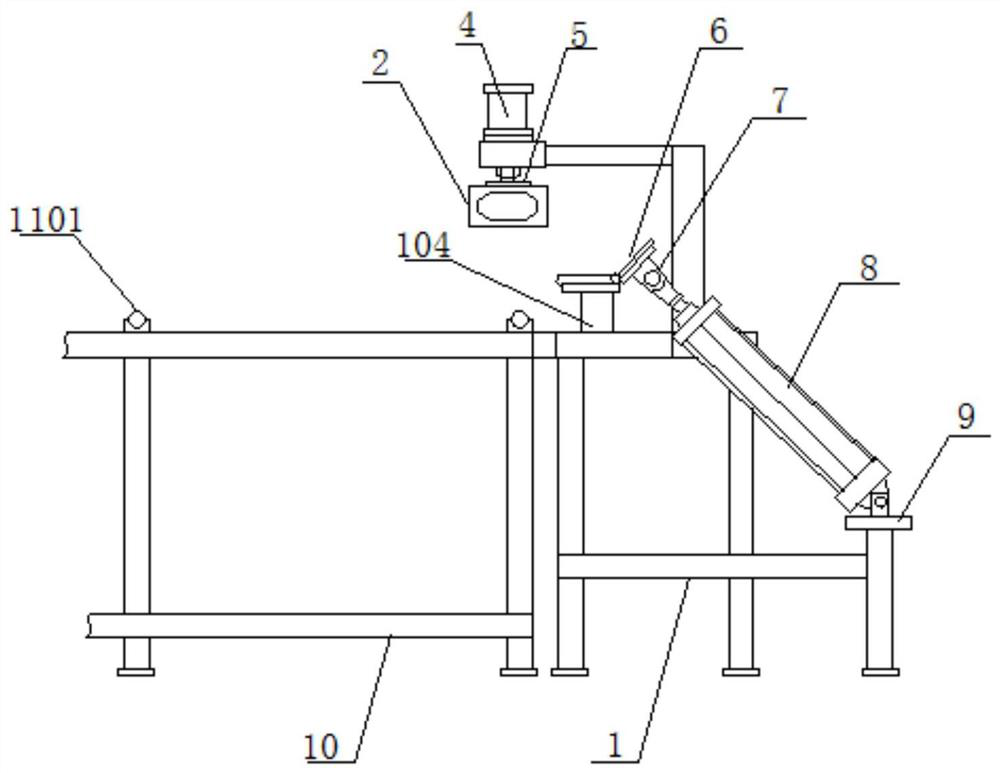

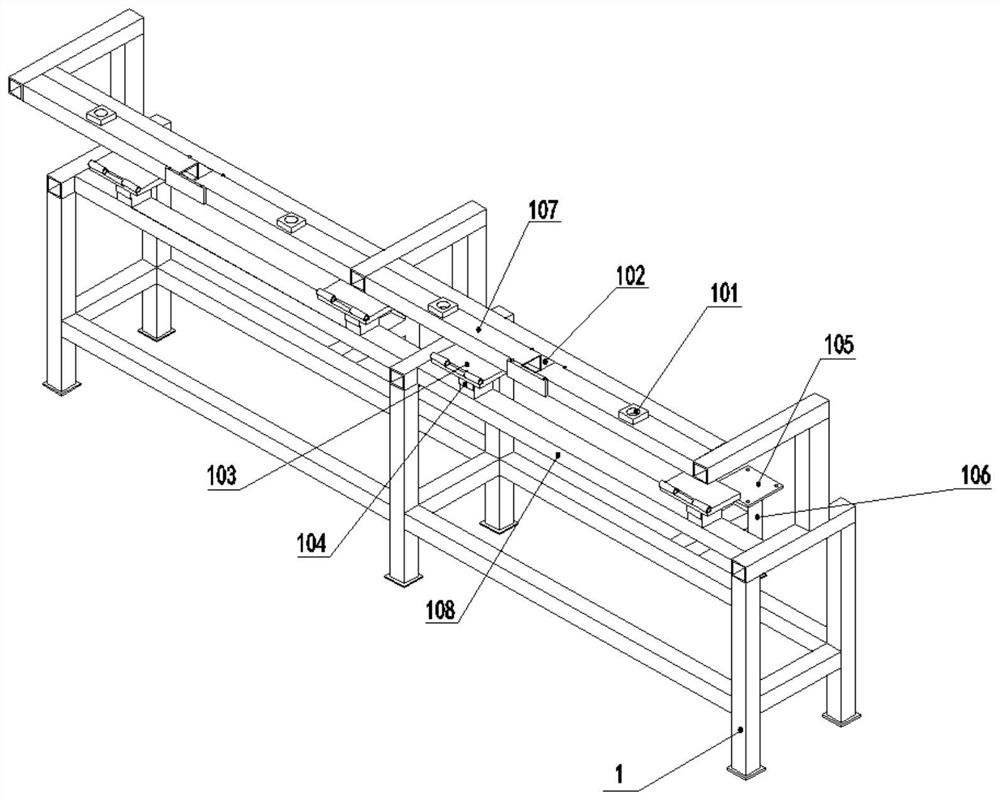

[0033] Such as Figure 1-9 As shown, a device for folding the bottom plate of a refrigerated compartment includes a bracket body 10, and the bracket body 10 is composed of a bracket body 1, a positioning block 2, a guide rod assembly 3, a vertical cylinder 4, and a vertical pin chain seat 5. It is composed of flanging platen 6, front pin chain seat 7, inclined push cylinder 8 and rear pin chain seat 9;

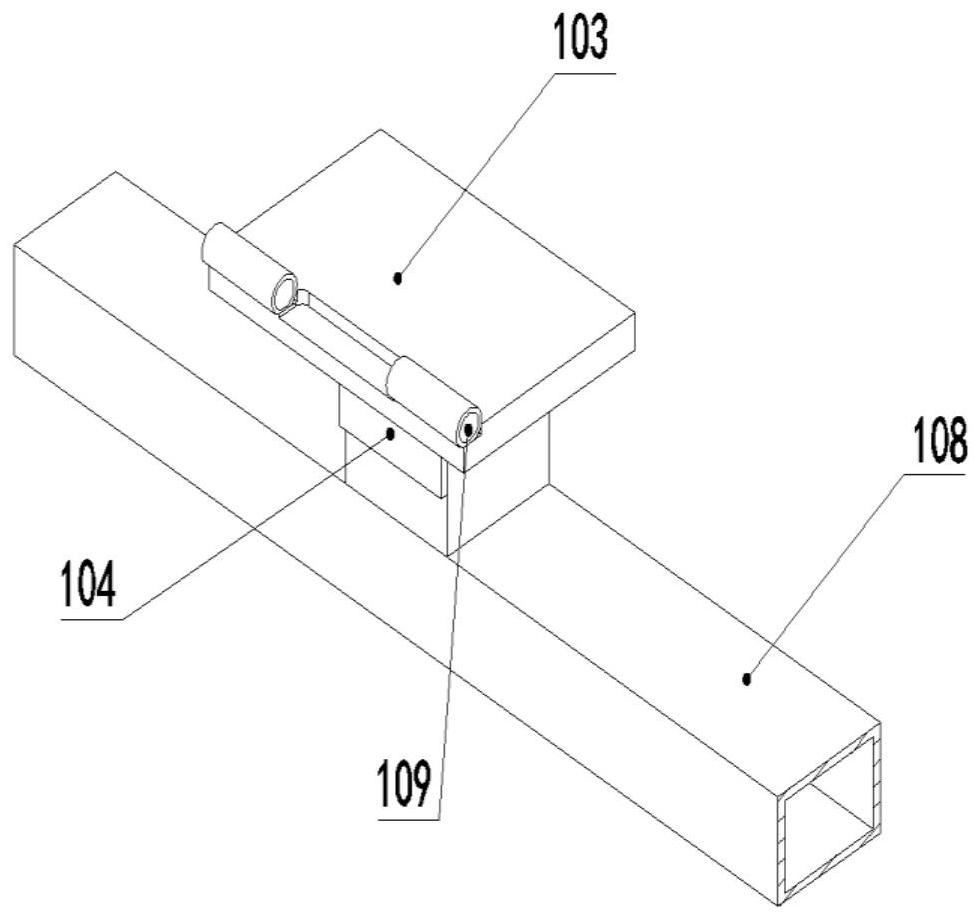

[0034] The support body 1 is made up of several unit frames with the same structure. The upper layer of each unit frame is a suspension beam 107, and the middle of the suspension beam 107 is provided with an installation square hole 102, and the left and right sides of the installation square hole 102 are provided with There are guide rod hole seats 101, and the middle layer of each unit frame is a support beam 108, and two hinge bases 103 are respectively arranged along the length of the support beam 108, and the front end of each hinge base 103 is fixedly connected with a F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com