Soldering flux sprinkling device capable of accurately controlling applying amount

A precise control and flux technology, applied in the direction of auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as difficulty in controlling the application amount, application position and adjustment flexibility of the fluxing device, and abnormal electrical properties of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

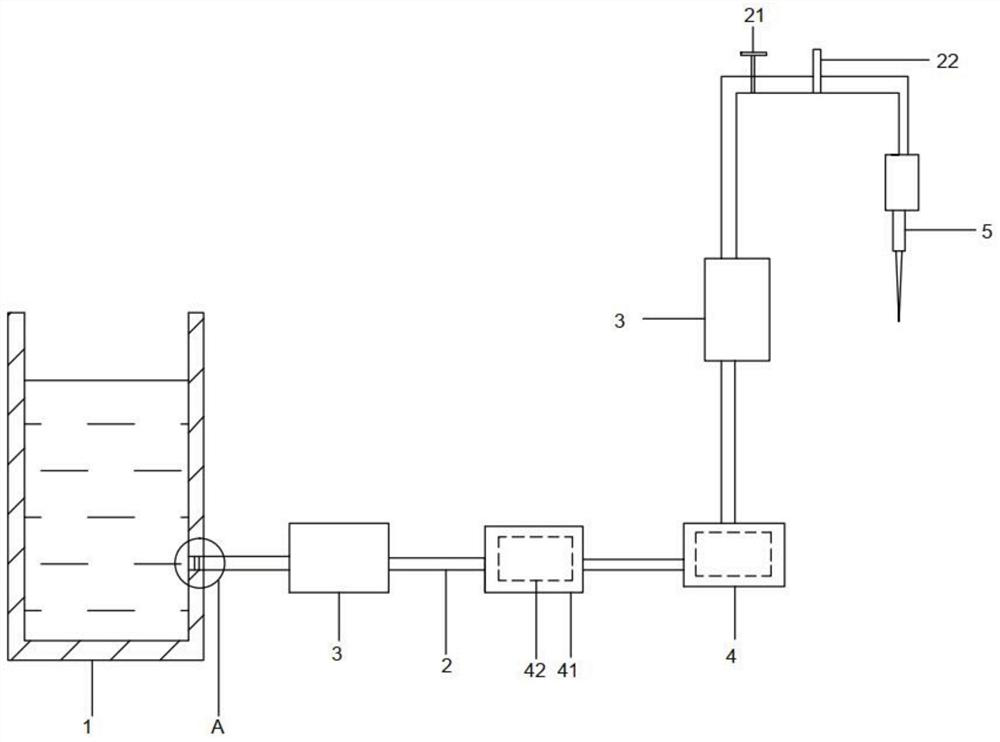

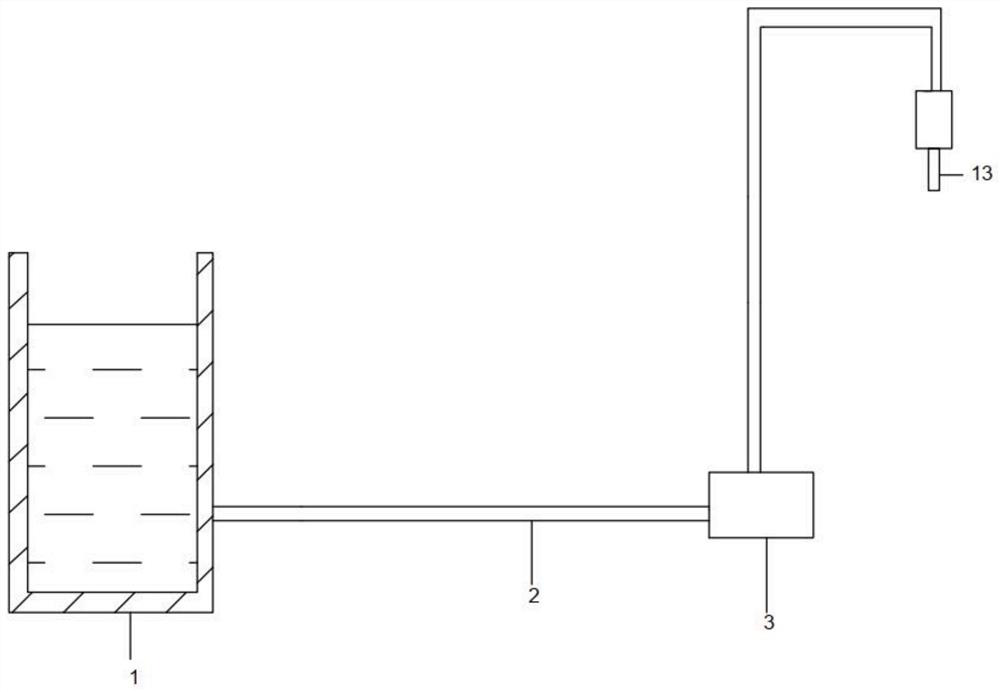

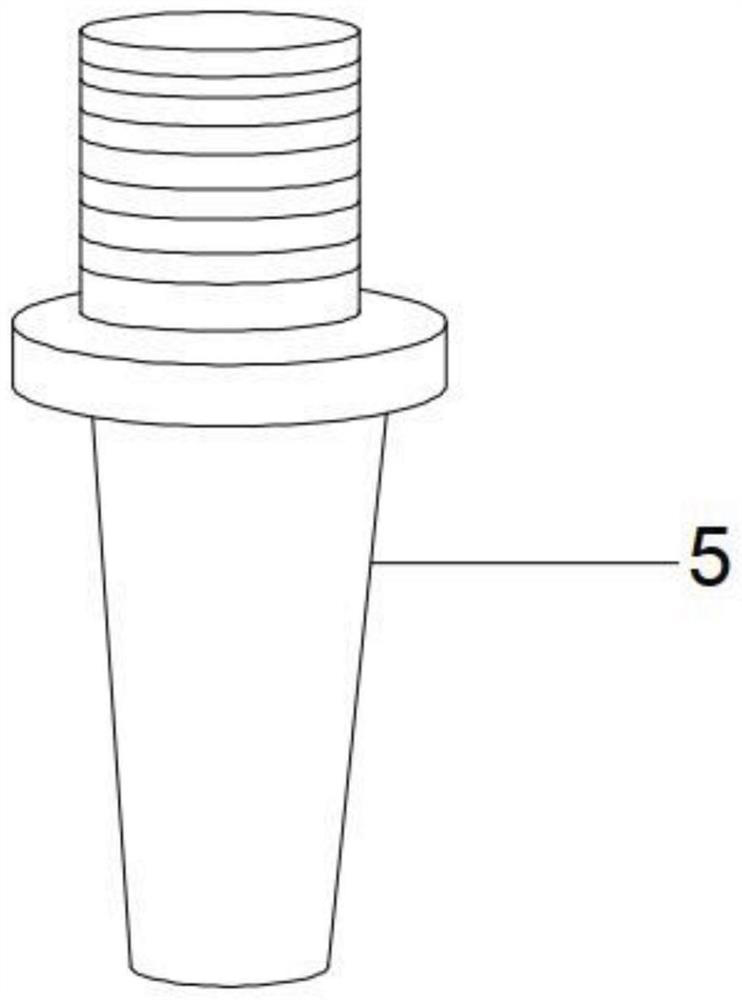

[0027] see Figure 1 to Figure 5 , the present embodiment provides a device for spraying flux with precise control of the amount applied. At least one water pump 3 is provided, and at least a filter 4 is provided on the conduit 2. The liquid outlet 11 of the conduit 2 is provided with a spray head 5. The spray head 5 includes a fixed head 51 and a needle 52, and the needle 52 is fixed on the fixed head. The needle 52 has a diameter of 0.16 mm, and a switch 21 is arranged on the catheter 2 .

[0028] continue to see Figure 1 to Figure 5 , one end of the conduit 2 located at the shower head 5 is provided with a flow meter 22 . The flow of flux can be monitored at any time to ensure the use of the device, avoid affecting product quality due to insufficient flux, and reduce unnecessary losses.

[0029] continue to see Figure 1 to Figure 5 , the liquid outlet of the conduit 2 has an internal thread. The fixing head 51 is provided with an external thread matching the internal...

Embodiment 2

[0037] see Figure 1 to Figure 5 , the figure shows a flux spraying device with precise control of the application amount provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: needle The diameter of 52 is 0.11mm, 0.12mm, 0.18mm, etc., and the diameter of needle 52 in this implementation is 0.16mm. Can achieve the best spray flux effect.

Embodiment 3

[0039] see Figure 1 to Figure 5 , the figure shows a device for spraying flux with precise control of the application amount provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: Conduit Two water pumps 3 are arranged on 2, and two filters 4 are also arranged on the conduit 2, and the two filters 4 are located between the two water pumps 3. Through the setting of the above structure, the functional failure caused by the blockage caused by foreign matter or other factors can be effectively prevented, and the cleanliness of the flux can be effectively maintained for a long time, and the water pump is added to ensure sufficient pressure to prevent fine-diameter blockage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com