Automatic and fast cementing device for oyster stick

A cement device and automatic technology, which can be used in surface layering devices, fish farming, ceramic molding machines, etc., can solve problems such as low work efficiency and uneven cement adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

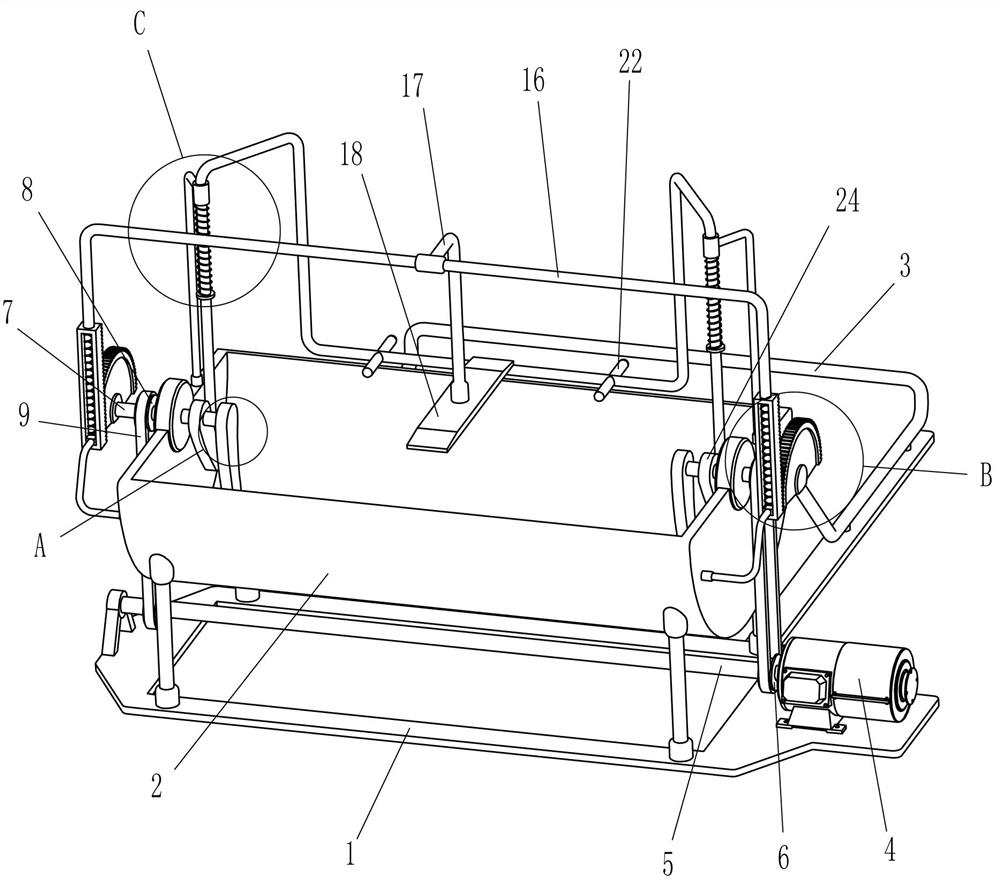

[0019] An automatic and fast cement wrapping device for oyster sticks, such as Figure 1-3 As shown, it includes a base 1, a semi-cylindrical frame 2, a special-shaped rod 3, a drive assembly, a salvage assembly, and a pressing assembly. The base 1 is provided with a semi-cylindrical frame 2, and the semi-cylindrical frame 2 is connected to the base 1. There is a special-shaped rod 3, the base 1 is provided with a drive assembly powered by a motor, the drive assembly is provided with a salvage assembly that is salvaged by rotation, and the semi-cylindrical frame 2 is provided with a push-down assembly that is pressed down by sliding. components.

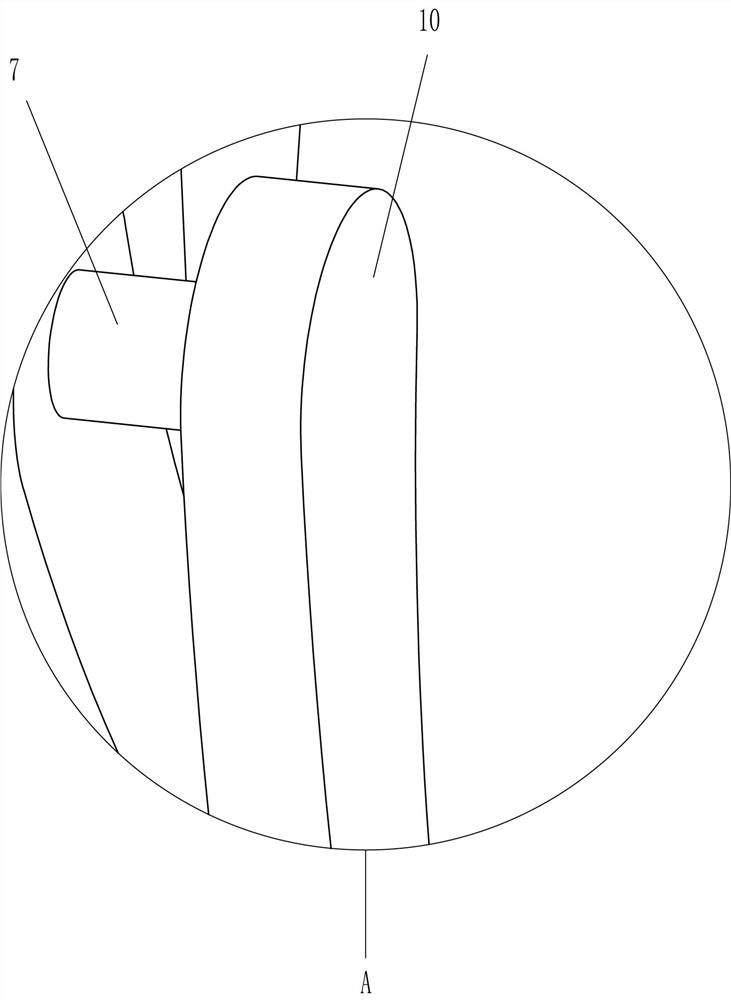

[0020] Such as figure 1 As shown, the driving assembly includes a reduction motor 4, a first rotating rod 5, a first pulley 6, a second rotating rod 7, a second pulley 8 and a flat belt 9, and the bottom right side of the base 1 is provided with a reduction motor 4, and the reduction motor 4 The output shaft of the output shaft is ...

Embodiment 2

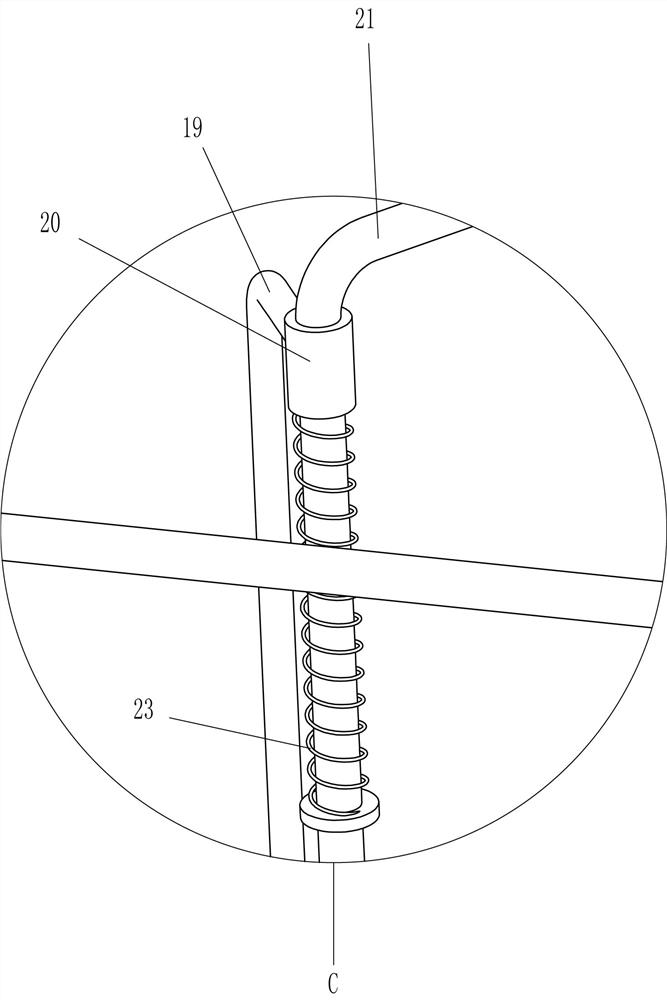

[0028] Such as figure 1 and 4 As shown, on the basis of Embodiment 1, in order to make the equipment work better, it also includes a second support rod 19, a sliding sleeve 20, a U-shaped rod 21, a cross bar 22, a second spring 23 and a push plate 24, The rear part of the left and right sides of the top of the semi-cylindrical frame body 2 is provided with a second support rod 19, and the tail end of the second support rod 19 is provided with a sliding sleeve 20, and a U-shaped rod 21 is slidably arranged in the sliding sleeve 20. The second spring 23 is connected between the bar 21 and the sliding sleeve 20, the U-shaped bar 21 is symmetrically provided with a horizontal bar 22, and the second rotating bar 7 is provided with a push plate 24, and the push plate 24 and the U-shaped bar 21 Fit both sides.

[0029] The specific implementation of the above embodiment: when the second rotating rod 7 rotates counterclockwise, it drives the push plate 24 to rotate counterclockwise,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com