Production device for preparing fish-flavored seasoning

A production device and seasoning technology, applied in the application, food forming, food processing and other directions, can solve the problems of reducing production efficiency, sticking fish scales on the inner wall of the container, time-consuming and laborious, etc., to improve efficiency, reduce water splash, The effect of reducing the pollution of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A production device for preparing fish-flavored seasonings, such as Figure 1-7 As shown, it includes a workbench 1, a first support frame 2, a support base 3, a second support frame 4, a heating assembly, a drive assembly, a first cleaning assembly, a second cleaning assembly, a drying assembly and a separation assembly; the workbench 1. The upper left part of the upper side is bolted with a first support frame 2; the upper right part of the workbench 1 is fixed with a support table 3; behind the support table 3; a heating assembly is installed on the inside of the first support frame 2; a driving assembly is installed on the upper part of the heating assembly; a first cleaning assembly is installed in the middle of the heating assembly; a second cleaning assembly is installed in the middle of the heating assembly, and the second cleaning assembly It is located below the first cleaning component; a drying component is installed on the upper part of the front side of th...

Embodiment 2

[0039] On the basis of Example 1, as figure 1 and Figure 8-10 As shown, the drying assembly includes a first telescopic cylinder 601, a third linkage block 602, a dryer 603, a pipeline 604, a third cylinder 605 and a positioning column 606; A telescopic cylinder 601; the telescopic end of the first telescopic cylinder 601 is fixed with a third linkage block 602; the lower side of the third linkage block 602 is fixed with a dryer 603; the front part of the dryer 603 is connected with a pipe 604; A third cylinder 605 is fixedly connected to the upper side; the pipe 604 communicates with the third cylinder 605 ; a positioning post 606 is welded to the upper left and upper right of the third cylinder 605 .

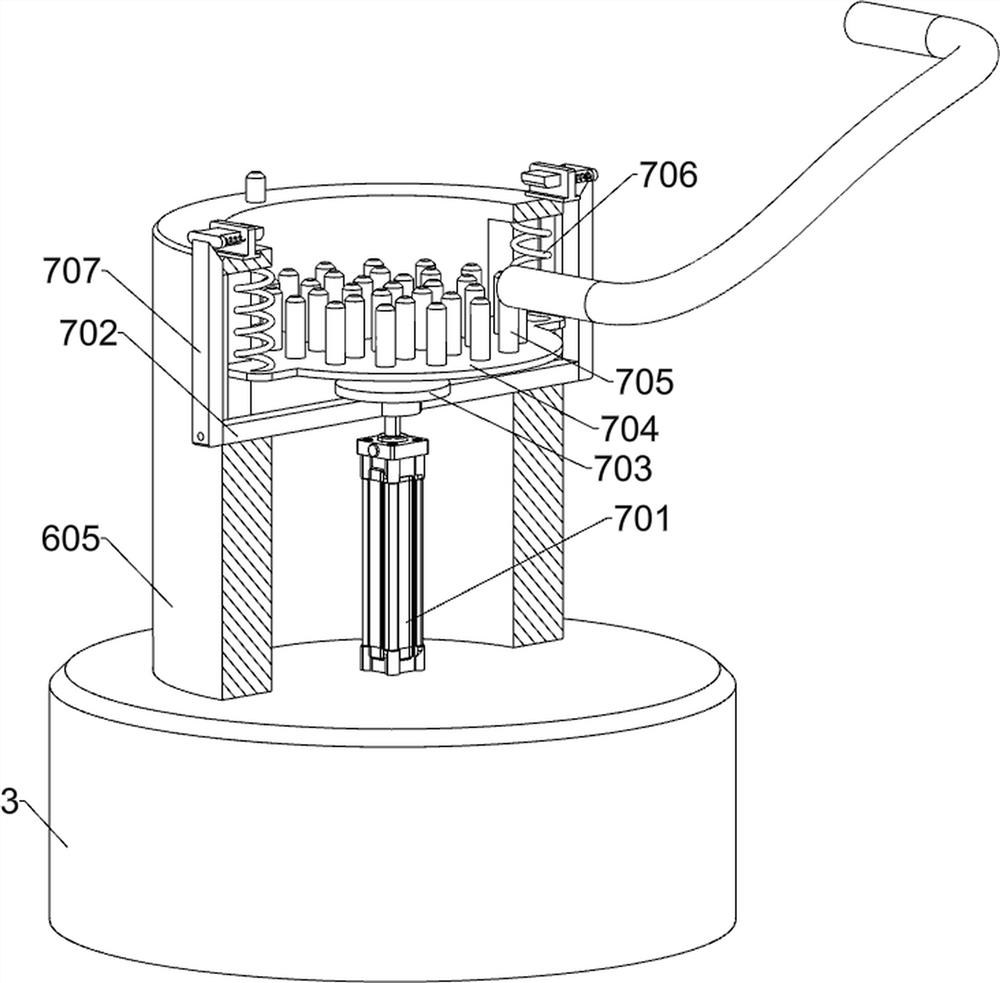

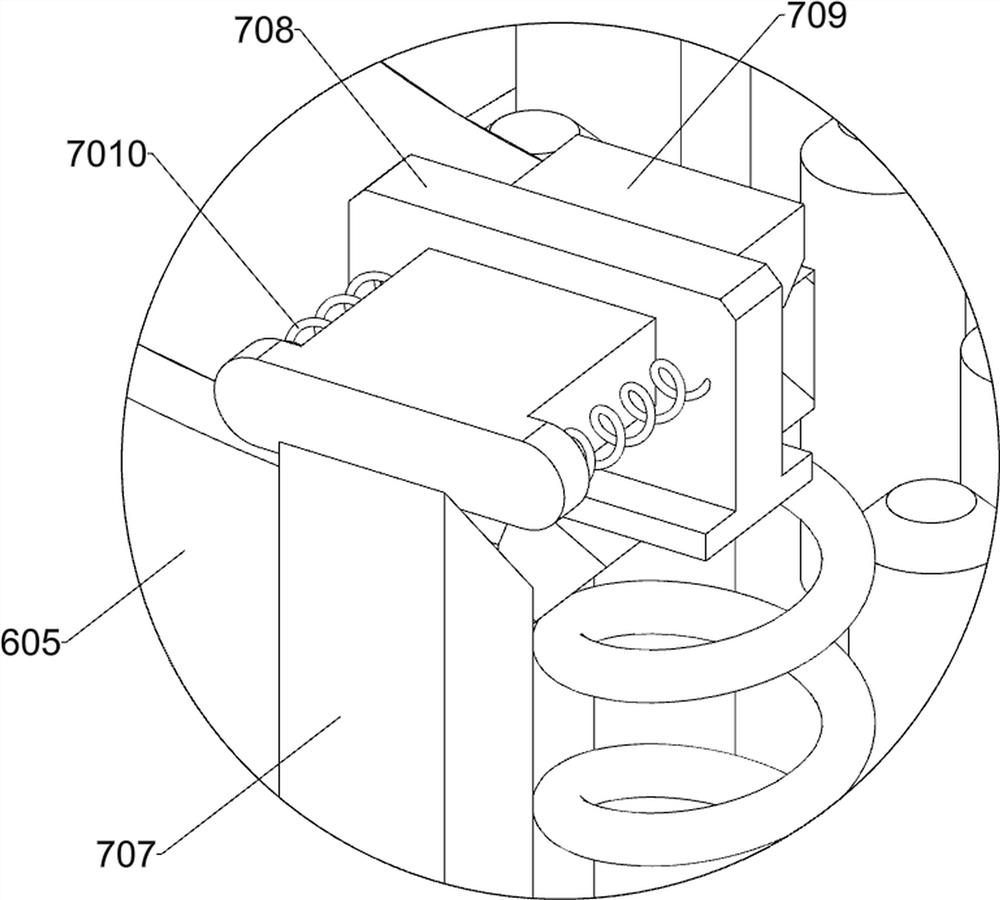

[0040] According to the present invention, the separation assembly includes a second telescopic cylinder 701, a linkage frame 702, a push plate 703, a sliding plate 704, a round rod 705, a third spring 706, a fourth linkage block 707, a second connection block 708, a push plat...

Embodiment 3

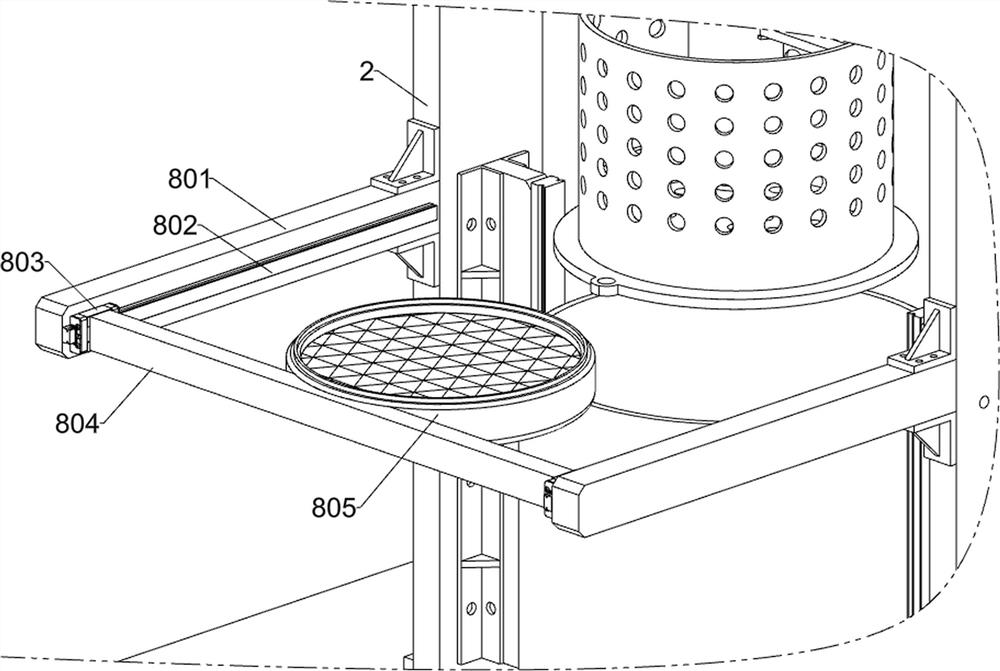

[0043] On the basis of Example 2, as figure 1 and Figure 11 As shown in the figure, it also includes a water absorbing assembly, and a water absorbing assembly is installed on the left side of the first support frame 2. The water absorbing assembly includes a connecting frame 801, a third electric sliding rail 802, a third electric sliding block 803, a linkage rod 804 and a water absorber 805. ; The lower left side of the first support frame 2 is bolted with two connecting frames 801; the opposite sides of the two connecting frames 801 are fixed with a third electric slide rail 802; the two third electric slide rails 802 are slidably connected with A third electric sliding block 803; two third electric sliding blocks 803 are fixedly connected with a linkage rod 804 on the opposite sides;

[0044] Working principle: After the cooking is completed, the two third electric sliders 803 slide to the right on the two third electric sliding rails 802 respectively, and the two third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com