An efficient cement mixer

A technology of cement mixer and mixing mechanism, which is applied in the direction of cement mixing device, mixing operation control, clay preparation device, etc., which can solve the problems of low mixing uniformity of the mixture and failure to fully mix the mixture, so as to reduce the possibility , Quickly and efficiently mix materials evenly, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

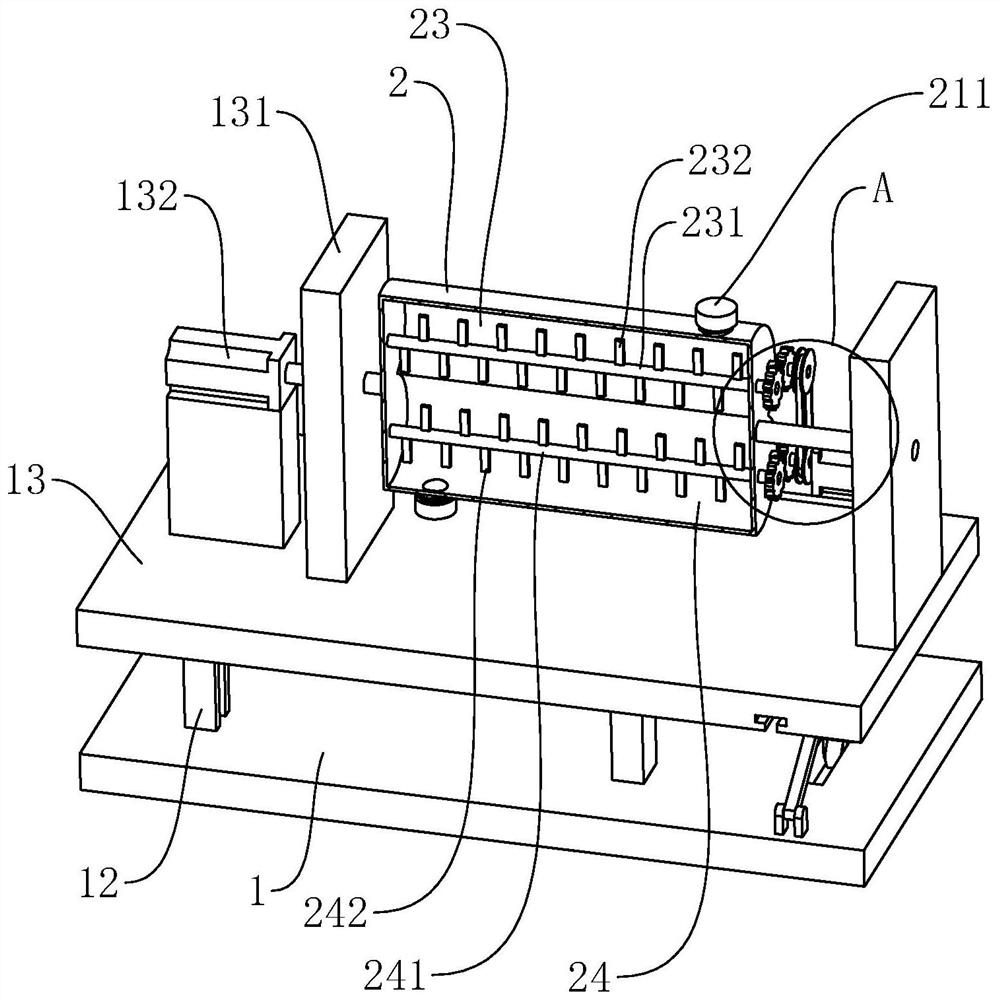

[0047] The present invention will be further described in detail below with reference to the accompanying drawings.

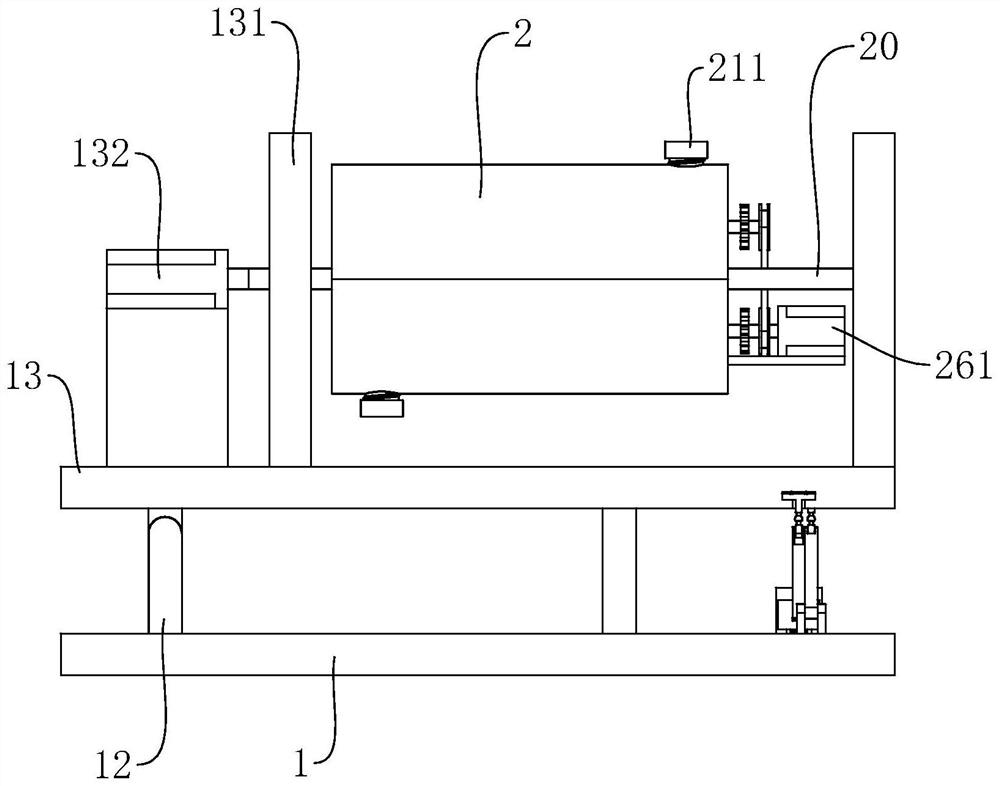

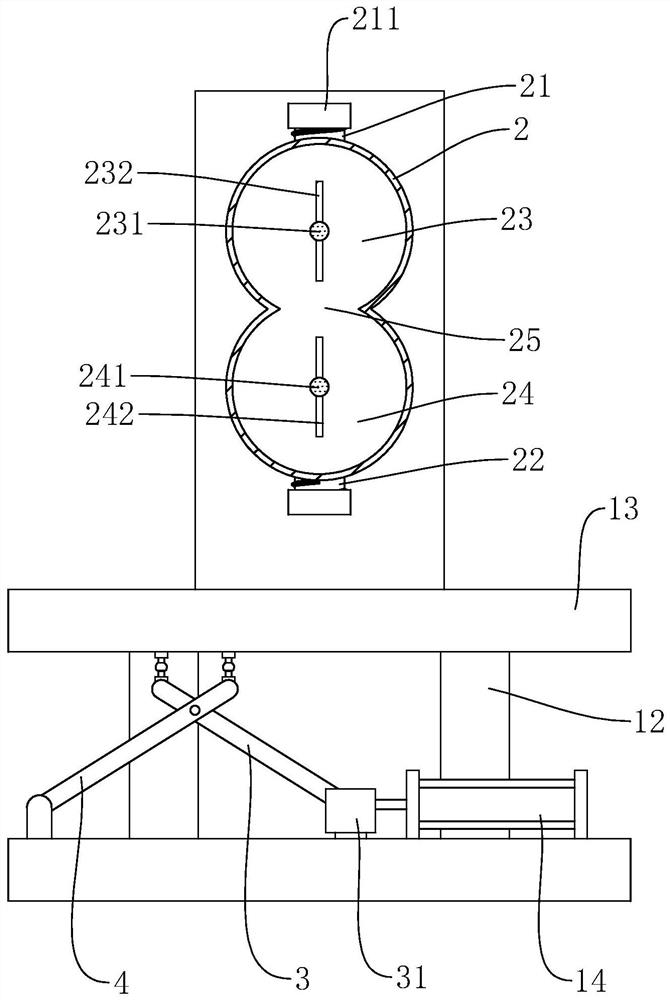

[0048] Refer figure 1 For a highly efficient cement mixer disclosed in the present invention, a square base 1 is provided, and four rectangular support columns 12 are provided on the base 1, and the four support post 12 is distinguished from one end of the base 1, which is provided with a support plate 13, support Two square mount 131 is mounted on the plate 13.

[0049] Refer figure 1 The two-piece mounting plates 131 are provided with a stirred tub 2, and the two ends in the longitudinal direction of the stirring tub are respectively mounted, and the two mounting shafts 20 are rotated from the two mounting plates 131, respectively. A drive motor 132 is provided on the support plate 13, and the mounting shaft 20 is distinguished from the upper end of the stirred tub 2 and is connected to the output shaft of the drive motor 132, and activates the drive motor 132 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com