Printing end of high-viscosity ink-jet printing head and high-viscosity ink-jet printing head

An inkjet print head, high viscosity technology, used in coating devices, additive manufacturing, processing heating elements, etc., can solve problems such as inability to eject viscosity, high materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

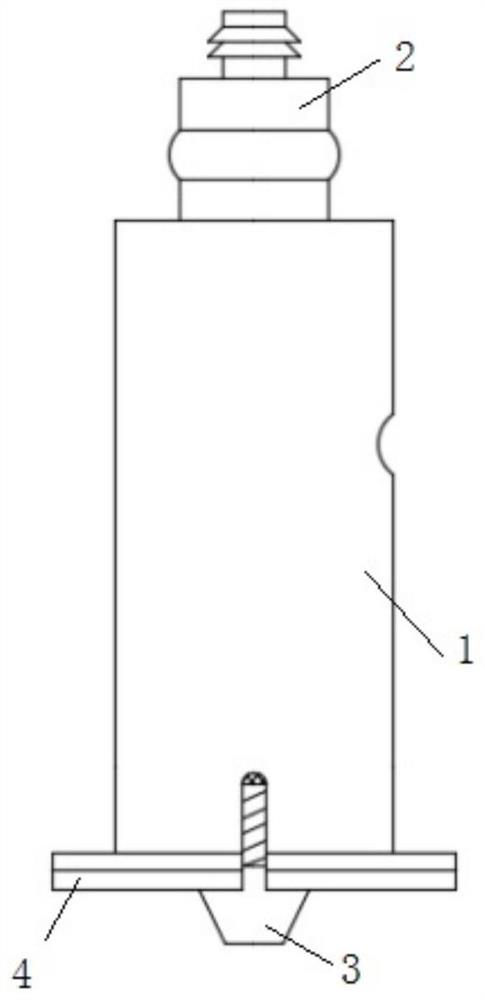

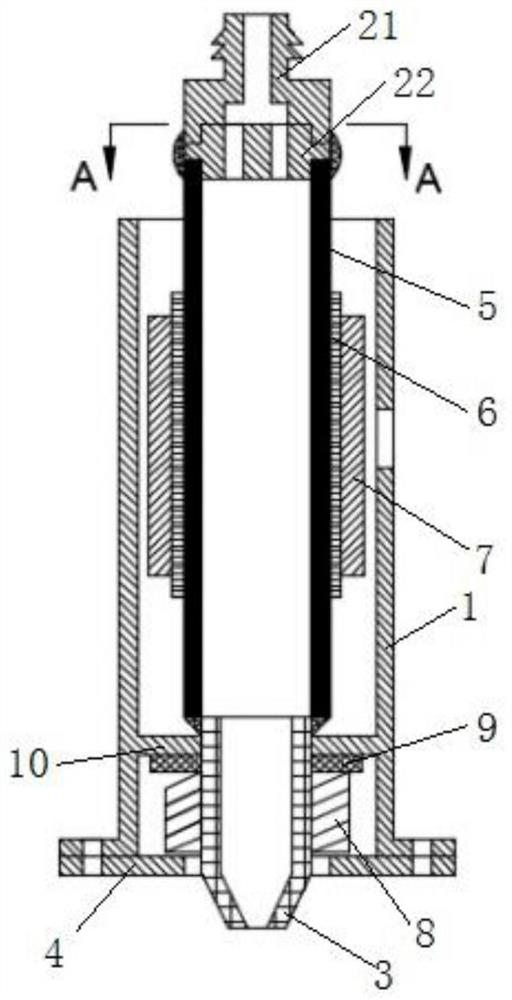

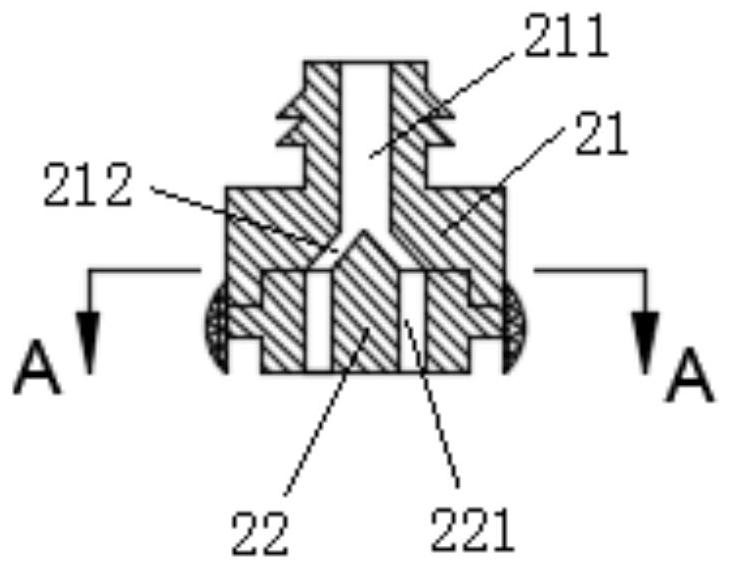

[0031] The invention discloses a printing end of a high-viscosity inkjet printing head, such as Figure 1~2 As shown, the printing end includes a casing 1, a PVDF tube 5, a piezoelectric ceramic tube 7 and a printing nozzle 3, the PVDF tube 5 and the piezoelectric ceramic tube 7 are located inside the casing 1, and the piezoelectric ceramic tube 7 is sleeved on the outside of the PVDF tube 5 , the printing nozzle 3 is arranged at the bottom of the PVDF pipe 5 and connected with the PVDF pipe 5 .

[0032] We use the PVDF tube 5 instead of the glass tube as the pressure chamber of the print head. The piezoelectric ceramic tube 7 is set on the PVDF tube 5 and the positive electrode of the piezoelectric ceramic tube 7 is led out with the conductive glue 6, and the wire is glued or welded with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com