Vacuum perfusion process for making composite flywheel rotor or part of rotor

A composite material and flywheel rotor technology, which is applied in the field of vacuum infusion technology, can solve the problems of composite material flywheel rotor or part of the rotor quality stability and FWF stability are difficult to guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

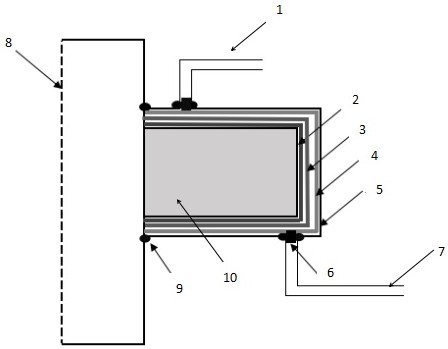

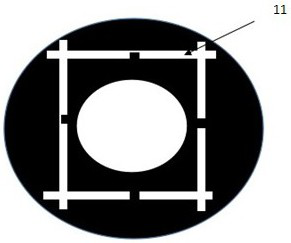

[0015] refer to Figure 1-2 , use carbon fiber or carbon-glass blended yarn / cloth to wrap around the specified inner cavity mold 8 under the tension of 145N-175N, and fix it with resin nails. At the end of carbon fiber or carbon-glass blended yarn / cloth, lay isolation film 2, guide net 3, and non-grinding cloth 4, and lay Ω vacuum perfusion pipe 11 at the center of the outer side, and three-way valve 6 respectively installed in the inner cavity The top and bottom of the mold 8 are connected to the position of the Ω vacuum perfusion tube 11 . The three-way valve 6 arranged above the inner cavity mold 8 is connected to the feeding pipe 1, and the three-way valve 6 arranged below the inner cavity mold 8 is connected to the vacuum pipe 7; a vacuum belt 5 is laid on the outside of the semi-permeable membrane and the Ω vacuum perfusion tube, The Ω vacuum perfusion tube 11 exposes the vacuum belt 5, and a sealing tape 9 is used to ensure airtightness. The other side of the three-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com