Automobile fuel tank

A technology of automobile fuel tank and fuel tank, which is applied in the direction of vehicle components, substructure, and the arrangement of the fuel supply of the internal combustion engine, etc., can solve the problems of affecting the running condition of the engine, difficult to remove dirt, and damage to the engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

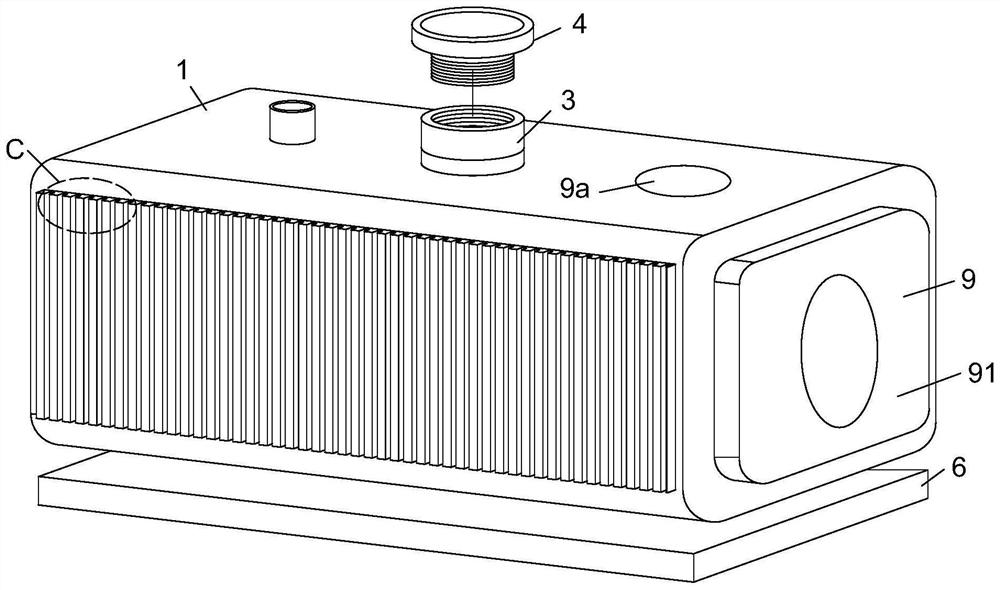

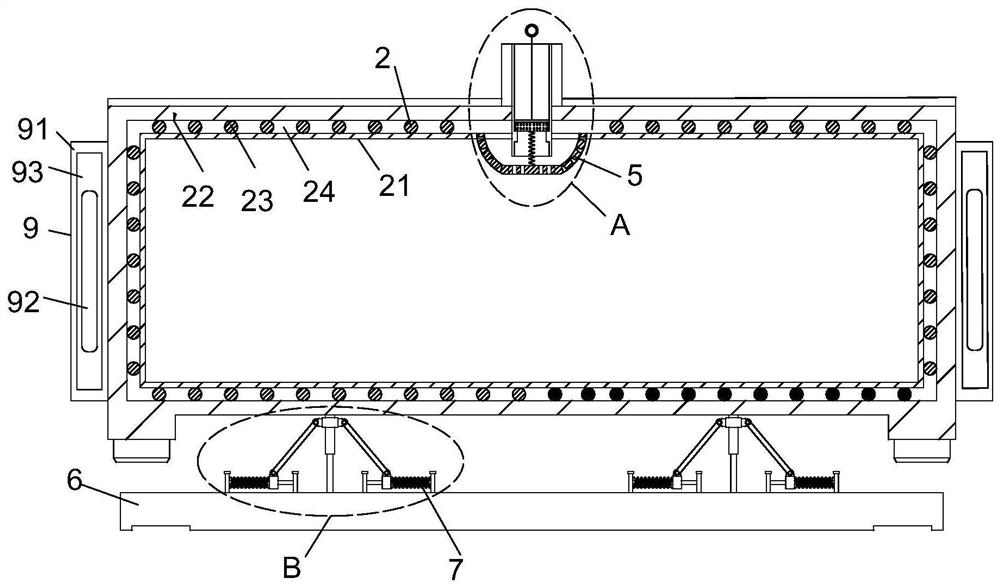

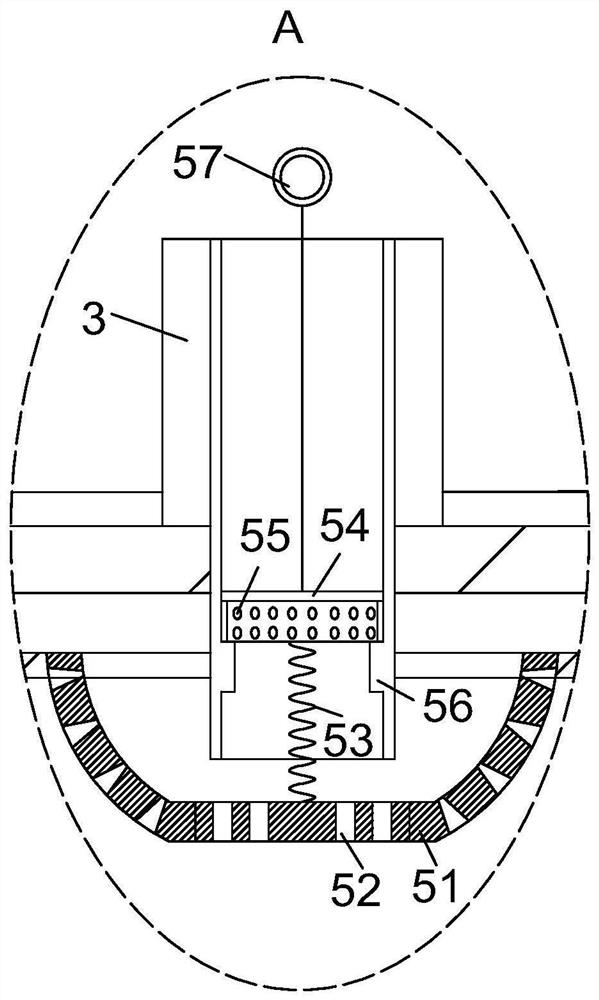

[0023] Please refer to Figure 1-5 As shown, a fuel tank for an automobile includes a fuel tank housing 1, a damage prevention mechanism 2, an oil inlet pipe 3, an anti-vibration mechanism 7, a protection mechanism 8 and an anti-collision mechanism 9; the damage prevention mechanism 2 is arranged inside the fuel tank housing 1, The anti-damage mechanism 2 includes an inner tank 21, an installation gap 22, a rubber ball 23 and deoxygenated water 24. The inner tank 21 is installed in the fuel tank shell 1, and the outer wall of the inner tank 21 is fixedly fitted with several uniform Distributed rubber balls 23, and each rubber ball 23 is fixedly fitted with the inner wall of the fuel tank shell 1, there is an installation gap 22 between the inner liner 21 and the fuel tank shell 1, and the installation gap 22 is filled with enough Amount of deoxygenated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com