A kind of 3D printing silicone rubber and its preparation method and application

A 3D printing and silicone rubber technology, which is applied in the field of 3D printing silicone rubber and its preparation, can solve the problems of single printing method, low cost, and low mechanical strength, and achieve simple and easy-to-control synthesis process, improved mechanical strength, and easy access to raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A 3D printing silicone rubber, comprising 2-12 parts of crosslinking agent, 18-31 parts of polydimethylsiloxane terminated by amino or hydroxyl group, 10-41 parts of diisocyanate, 5-35 parts of aminopyrazole compound, 20 ~50 parts solvent.

[0040] The preparation method of described 3D printing silicone rubber is:

[0041] Step 1: Weigh 2 to 12 parts of crosslinking agent, 18 to 31 parts of amino or hydroxyl terminated polydimethylsiloxane, 10 to 41 parts of diisocyanate, 5 to 35 parts of aminopyrazole compound, 20 to 50 parts of solvent, and dissolve the raw materials in the solvent to obtain a reaction liquid, and stir and react at room temperature for 2 to 10 hours to obtain a prepolymer;

[0042] Step 2: Pour the polymer obtained in Step 1 into a mold, put it in an oven at 80°C to remove the solvent and continue curing for 10 to 96 hours. The solvent vapor is recovered by a solvent recovery machine. 3D-printed silicone rubber solids with dynamic bonds of fenoxuro...

Embodiment 2

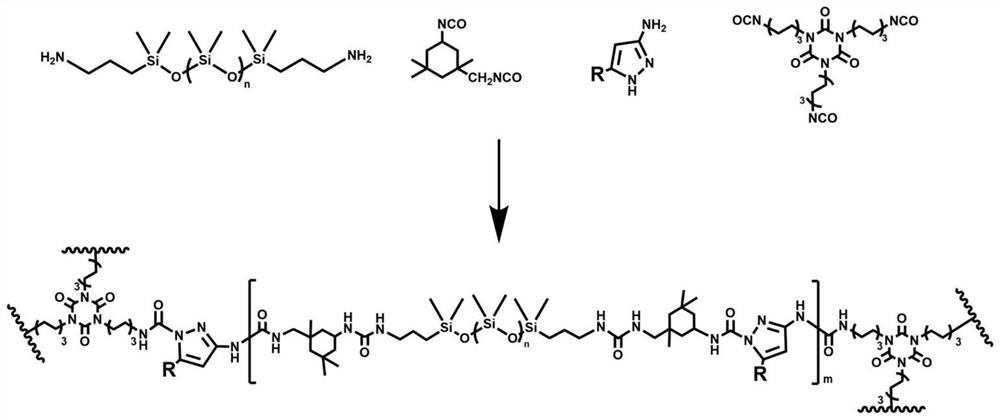

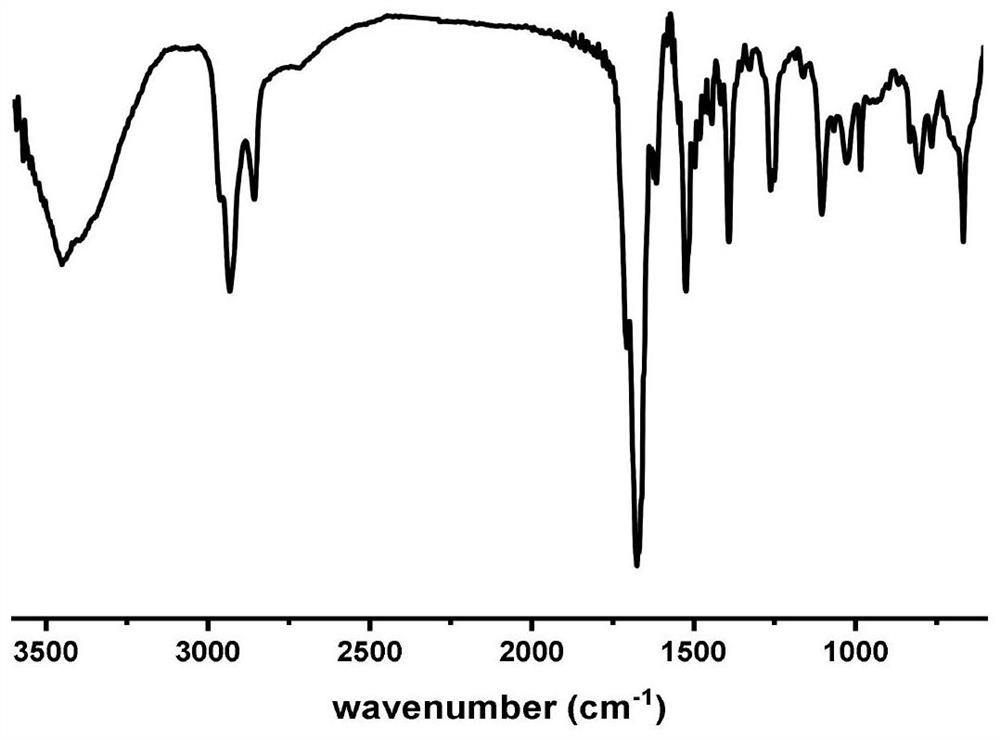

[0052] 5.4 g of aminopropyl-terminated polydimethylsiloxane DMS-A15, 0.532 g of isophorone diisocyanate, 0.1 g of 3-amino-5-tert-butylpyrazole, and 0.2 g of hexamethylene diisocyanate trimerized The solid was dissolved in 20ml of tetrahydrofuran, and stirred at room temperature for 3 hours to obtain a prepolymer after the reaction was completed. The prepolymer obtained by the reaction was poured into a polytetrafluoroethylene mold, and then placed in an oven at 80°C to continue curing for 24 hours, and then from Take out the silicone rubber solid containing pyrazole urea dynamic bond from the mold, the raw material and the chemical structure of the synthetic silicone rubber are as follows: figure 1 As shown, the obtained silicone rubber is detected by infrared spectroscopy, and the detection results are as follows figure 2 As shown, the actual image 3 shown. The powder obtained after pulverizing the silicone rubber solid in a low-temperature pulverizer is as follows: Fig...

Embodiment 3

[0055] Use 5.4g of aminopropyl-terminated polydimethylsiloxane DMS-A15, 0.532g of isophorone diisocyanate, 0.08g of p-phenylenediamine and 0.2g of hexamethylene diisocyanate trimer dissolved in 20ml of tetrahydrofuran , stirred and reacted at room temperature for 3 hours. After the reaction, pour the prepolymer into a polytetrafluoroethylene mold, and then put it in an oven at 80°C to continue curing for 24 hours. After that, it was taken out from the mold to obtain a non-dynamic polymer containing ordinary urea bonds. Compared to silicone rubber solids.

[0056] Embodiment 2 is obtained the silicone rubber solid containing pyrazole uron dynamic bond (such as Figure 9 shown) and the non-dynamic contrast silicone rubber solid containing common urea bonds obtained in Example 3 (such as Figure 10 shown) under the conditions of 120 ° C and 10 MPa for 30 minutes, respectively, the shapes of the silicone rubber solid containing pyrazolamide dynamic bonds and the non-dynamic contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com