A kind of opening device for producing polypropylene staple fiber non-woven geotextile

A technology of non-woven geotextiles and opening devices, which is applied to fiber opening and cleaning machines, opening and cleaning with toothed tools, etc., which can solve the problems of poor separation effect and affecting the quality of opening, so as to improve the quality and efficiency of opening , Improve the opening efficiency and make the fiber cluster fluffy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

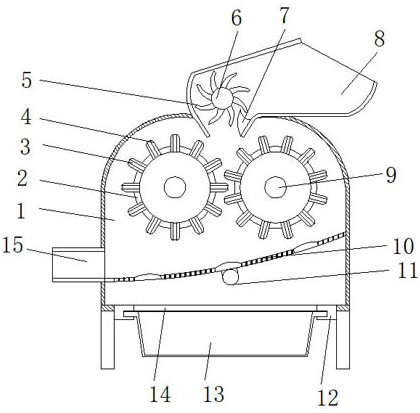

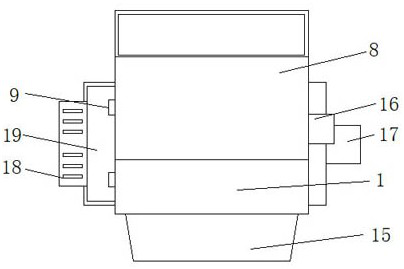

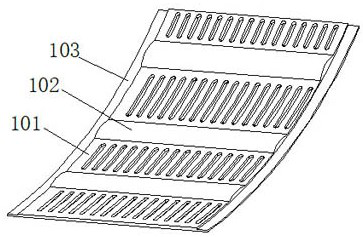

[0028] refer to Figure 1-4 , an opening device for producing polypropylene staple fiber non-woven geotextiles, comprising a casing 1, a feeding hopper 8 is fixedly installed on the top of the casing 1, and a feeding pipe 15 is fixedly installed on the bottom of the side of the casing 1, Two rollers 2 are installed inside the housing 1 through bearings, and the side of the housing 1 is fixedly installed with a driving mechanism 17 that is connected to the two rollers 2 in a driving manner. The inner bottom end of the body 1 is fixedly installed with the filter mechanism 10, and the bottom end of the filter mechanism 10 is fixedly installed with the vibration motor 11, the bottom of the casing 1 is provided with a rectangular groove 14, and the inner ends of the rectangular groove 14 are fixedly installed. In the support groove 12 of the U-shaped structure, a collection box 13 is inserted between the inner parts of the two support grooves 12 , a driving motor 16 is fixedly inst...

Embodiment 2

[0036] refer to Figure 2-5 , an opening device for making polypropylene staple fiber non-woven geotextiles. Compared with the first embodiment, the outer side of the feeding pipe 15 is fixedly installed with a collection cover mechanism, and the bottom end of the collection cover mechanism is through the hasp The lock is provided with a collecting box 21;

[0037] The collection cover mechanism includes a collection pipe 20 with an L-shaped structure, and a plurality of filter air holes 22 are arranged on the outer side of the collection pipe 20 , and a noise-absorbing mesh cover 23 is fixedly installed on the outer side of the collection pipe 20 .

[0038] When this embodiment is used, when the device is unloading, the fibers opened in the shell 1 are transported outward by the wind force, enter the device and filter into the collecting box 21, which improves the convenience of the device for unloading, and the operation is simple and convenient. , and the noise-absorbing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com