A production process of yak wool/wool blended yarn woven fabric

A technology of wool blended yarn and production process, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, textile, etc., and can solve the problems of low utilization rate, low spinnability and low value of yak wool, etc. To achieve the effect of stimulating ecological breeding, increasing added value and increasing diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

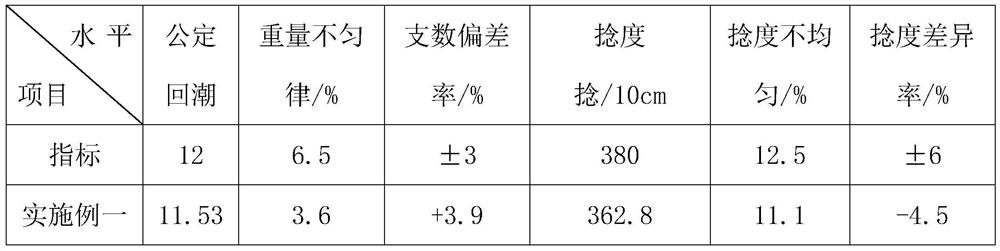

Embodiment 1

[0030] The production process of a yak hair / wool blended yarn woven fabric involved in this embodiment includes the following steps: woven fabric preparation—repair—blank inspection—sewing bag—shrinkage—wet inspection—drying—intermediate inspection - Cooking - steaming - steel wire fluffing - thorn fruit fluffing - shaping - drying - shearing - ironing - shearing - finished product - packaging.

[0031] In the preparation of the woven fabric, the warp and the weft are interwoven with a satin weave; the warp is a worsted wool yarn, and the weft is a plied yarn of two yak hair / wool blended yarns; the content of the yak hair in the weft is 60-70%. %. The weaving is carried out on a loom imported from Italy, and the weft yarn is the above-mentioned yak hair / wool blended plied yarn. The combination of the two improves the strength of the yarn and reduces the difficulty of weaving. The weave is 8-piece satin weave, the upper machine warp density is 185 pieces / 10cm, and the upper ma...

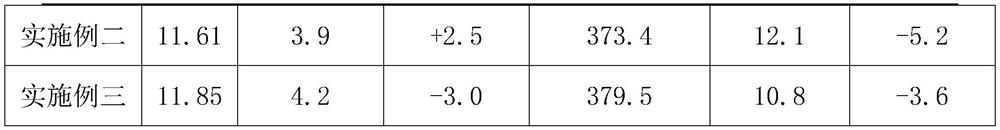

Embodiment 2

[0053] The production process of a yak hair / wool blended yarn woven fabric involved in this embodiment includes the following steps: woven fabric preparation—repair—blank inspection—sewing bag—shrinkage—wet inspection—drying—intermediate inspection - Cooking - steaming - steel wire fluffing - thorn fruit fluffing - shaping - drying - shearing - ironing - shearing - finished product - packaging.

[0054] In the preparation of the woven fabric, the warp and the weft are interwoven with a satin weave; the warp is a worsted wool yarn, and the weft is a plied yarn of two yak hair / wool blended yarns; the content of the yak hair in the weft is 60-70%. %. The weaving is carried out on a loom imported from Italy, and the weft yarn is the above-mentioned yak hair / wool blended plied yarn. The combination of the two improves the strength of the yarn and reduces the difficulty of weaving. The weave is 8-piece satin weave, the upper machine warp density is 185 pieces / 10cm, and the upper ma...

Embodiment 3

[0076] The production process of a yak hair / wool blended yarn woven fabric involved in this embodiment includes the following steps: woven fabric preparation—repair—blank inspection—sewing bag—shrinkage—wet inspection—drying—intermediate inspection - Cooking - steaming - steel wire fluffing - thorn fruit fluffing - shaping - drying - shearing - ironing - shearing - finished product - packaging.

[0077] In the preparation of the woven fabric, the warp and the weft are interwoven with a satin weave; the warp is a worsted wool yarn, and the weft is a plied yarn of two yak hair / wool blended yarns; the content of the yak hair in the weft is 60-70%. %. The weaving is carried out on a loom imported from Italy, and the weft yarn is the above-mentioned yak hair / wool blended plied yarn. The combination of the two improves the strength of the yarn and reduces the difficulty of weaving. The weave is 8-piece satin weave, the upper machine warp density is 185 pieces / 10cm, and the upper ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com