Production process of yak hair/wool blended yarn woven fabric

A wool blended yarn, production process technology, applied in the processing of textile materials, liquid/gas/vapor textile material processing, weaving, etc., can solve the problems of low value, low spinnability of yak wool, low utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

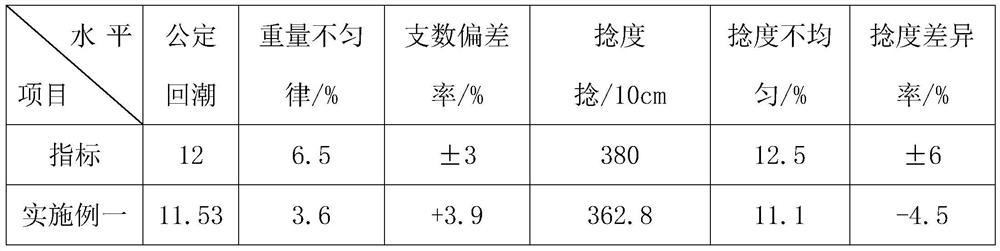

Embodiment 1

[0030] The production process of a yak wool / wool blended yarn woven fabric involved in this embodiment includes the following steps: woven fabric preparation—repair—blank inspection—sewing bag—shrinkage—wet inspection—drying—intermediate inspection -Cooked trimming-steaming-steel wire fluffing-thorn fruit fluffing-setting-drying-shearing-scalding-shearing-finished product-packing.

[0031] In the preparation of woven fabrics, the warp and weft yarns are interwoven with satin weave; the warp yarns are worsted wool yarns, and the weft yarns are ply yarns of two yak hair / wool blended yarns; the content of yak hair in the weft yarns is 60-70 %. Imported Italian looms are used for weaving, and the weft yarn is the above-mentioned yak hair / wool blended double-ply yarn. The combination of the two improves the yarn strength and reduces weaving difficulties. The fabric structure adopts 8 pieces of satin weaving, the warp density of the upper machine is 185 threads / 10cm, and the weft d...

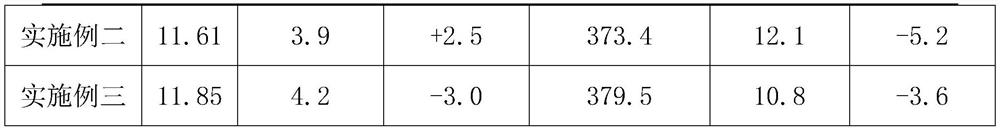

Embodiment 2

[0053] The production process of a yak wool / wool blended yarn woven fabric involved in this embodiment includes the following steps: woven fabric preparation—repair—blank inspection—sewing bag—shrinkage—wet inspection—drying—intermediate inspection -Cooked trimming-steaming-steel wire fluffing-thorn fruit fluffing-setting-drying-shearing-scalding-shearing-finished product-packing.

[0054] In the preparation of woven fabrics, the warp and weft yarns are interwoven with satin weave; the warp yarns are worsted wool yarns, and the weft yarns are ply yarns of two yak hair / wool blended yarns; the content of yak hair in the weft yarns is 60-70 %. Imported Italian looms are used for weaving, and the weft yarn is the above-mentioned yak hair / wool blended double-ply yarn. The combination of the two improves the yarn strength and reduces weaving difficulties. The fabric structure adopts 8 pieces of satin weaving, the warp density of the upper machine is 185 threads / 10cm, and the weft d...

Embodiment 3

[0076] The production process of a yak wool / wool blended yarn woven fabric involved in this embodiment includes the following steps: woven fabric preparation—repair—blank inspection—sewing bag—shrinkage—wet inspection—drying—intermediate inspection -Cooked trimming-steaming-steel wire fluffing-thorn fruit fluffing-setting-drying-shearing-scalding-shearing-finished product-packing.

[0077] In the preparation of woven fabrics, the warp and weft yarns are interwoven with satin weave; the warp yarns are worsted wool yarns, and the weft yarns are ply yarns of two yak hair / wool blended yarns; the content of yak hair in the weft yarns is 60-70 %. Imported Italian looms are used for weaving, and the weft yarn is the above-mentioned yak hair / wool blended double-ply yarn. The combination of the two improves the yarn strength and reduces weaving difficulties. The fabric structure adopts 8 pieces of satin weaving, the warp density of the upper machine is 185 threads / 10cm, and the weft d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com