Self-netting type scattered-point internal vibration ball for concrete pouring

A concrete and net-type technology, which is applied in construction, building structure, and building material processing, can solve problems such as difficulty in ensuring the personal safety of technicians, increased construction costs, and insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

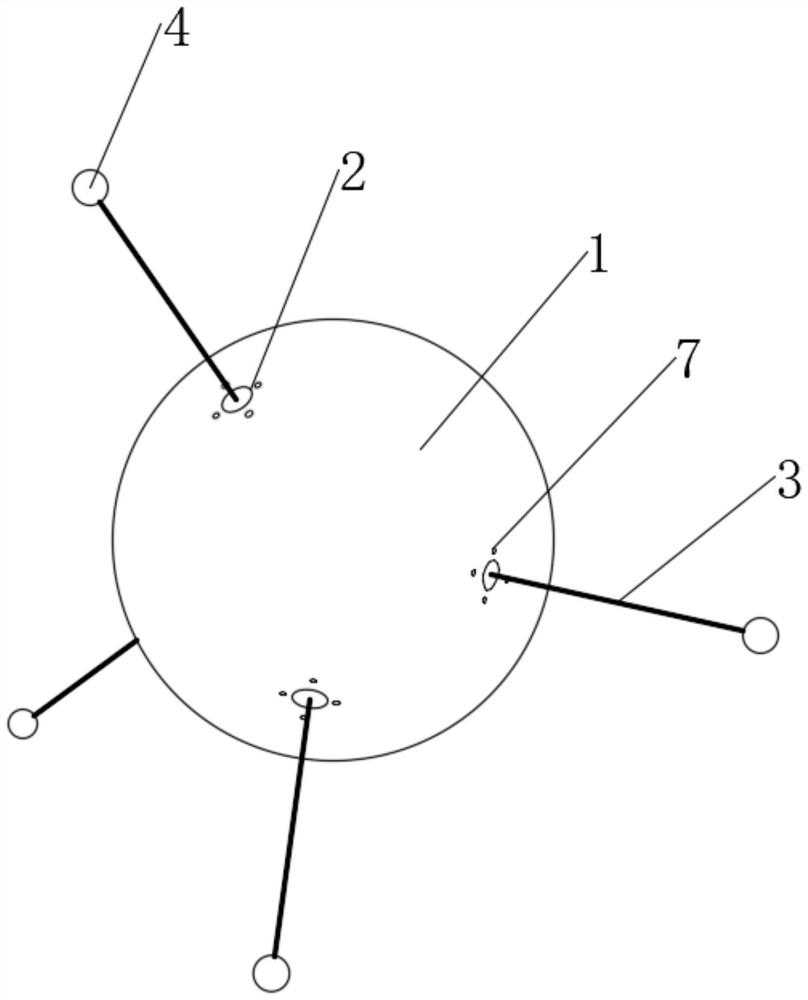

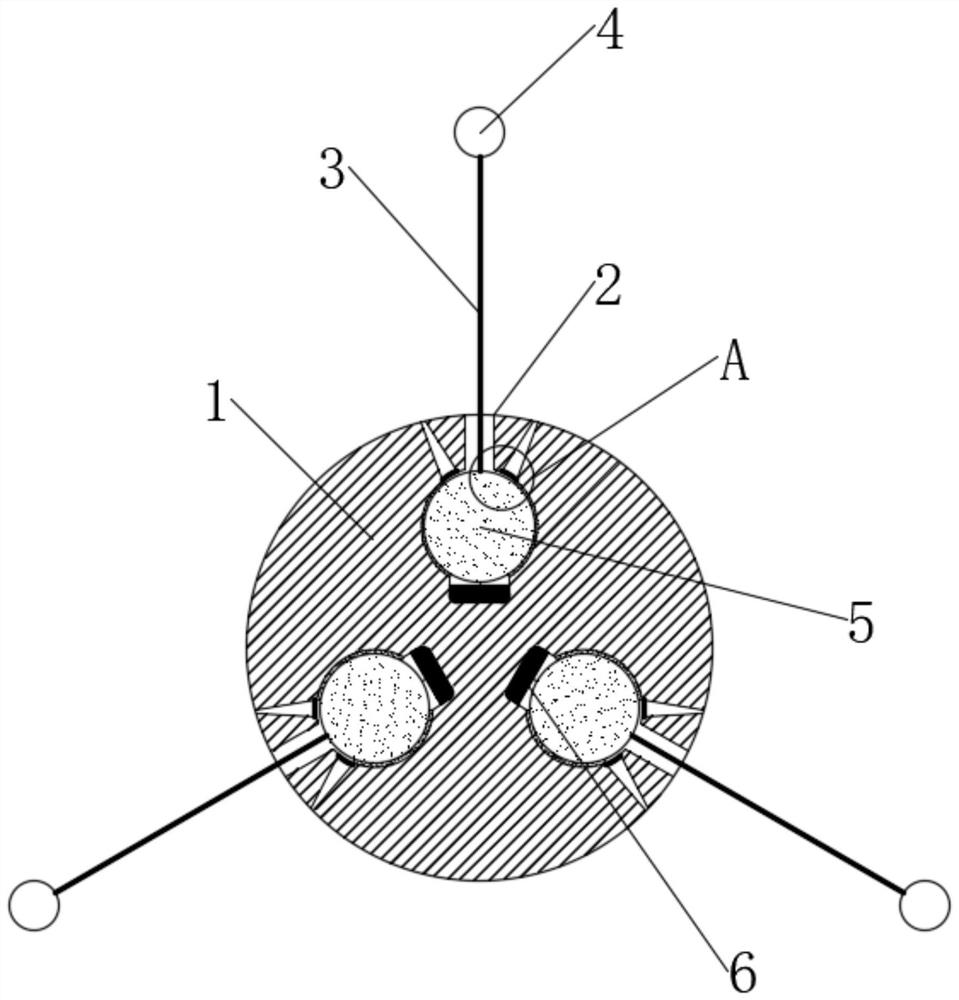

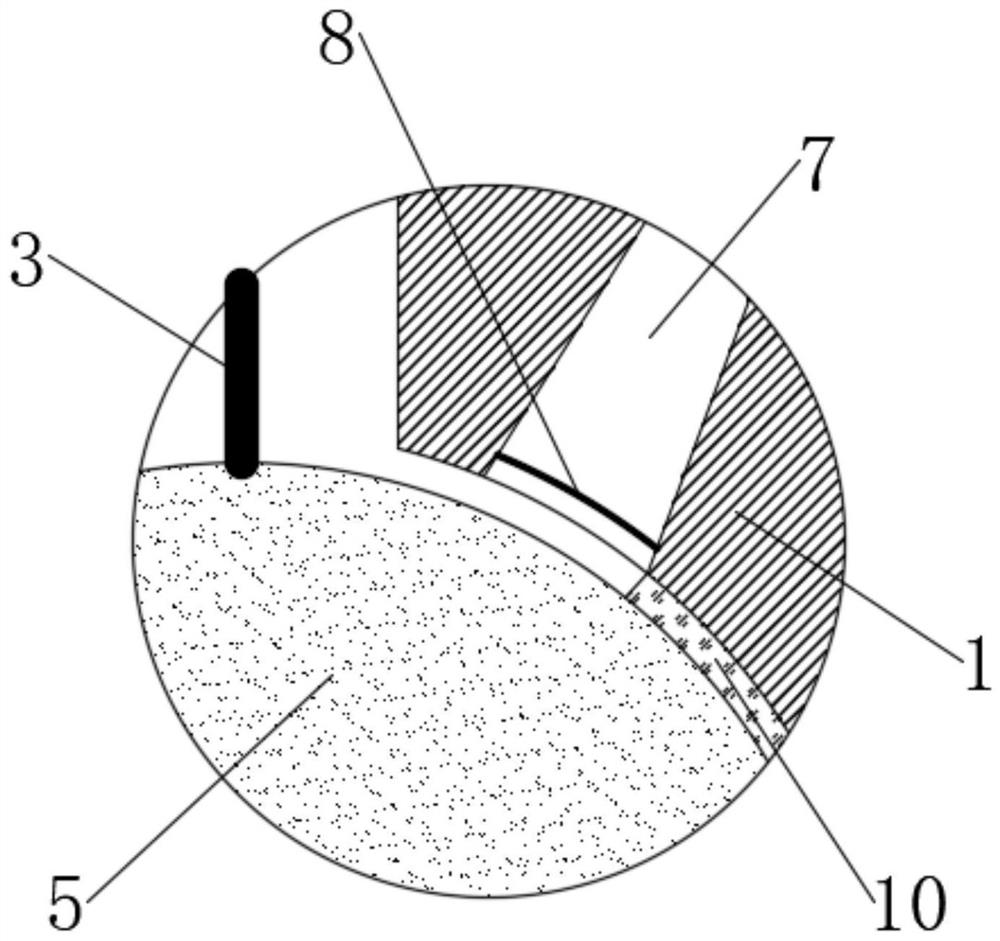

[0044] see Figure 1-3 , a self-netting scatter-point internal vibrating ball for concrete pouring, comprising an internal vibrating sphere 1, a plurality of evenly distributed water-disintegrating vibrating balls 5 are inlaid and connected in the internal vibrating sphere 1, and the internal vibrating sphere 1 adopts high-strength The water disintegrating vibrating ball 5 is made of effervescent disintegrating agent. The internal vibrating ball 1 can be directly embedded in the concrete to play a local strengthening role and improve the mechanical strength of the area. The water disintegrating vibrating ball 5 When encountering the moisture in the concrete, the disintegration reaction occurs quickly, and a large amount of gas is released, which causes the high-frequency vibration of the inner vibrating sphere 1, and vibrates the concrete. At the same time, the gas passes through the escape hole 7 when it escapes. Form tiny air bubbles in the concrete to improve the performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com