Casing based on self-circulation oscillation jet, compressor and stability enhancing method thereof

A technology of oscillating jet flow and self-circulation, which is applied to components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., and can solve problems such as poor safety, low reliability, and high reliability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

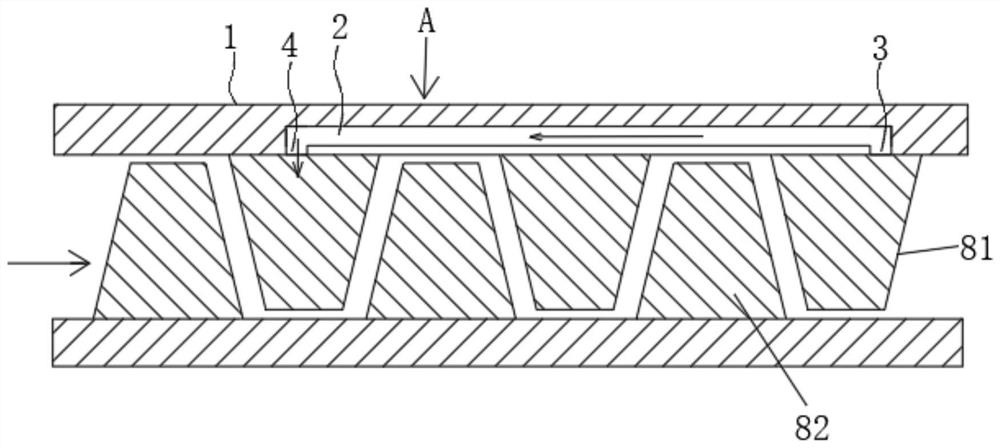

[0058] refer to figure 1 and figure 2 , a casing 1 based on a self-circulating oscillating jet, the casing 1 is provided with a fluid oscillator channel 2; in this embodiment, the fluid oscillator channel 2 adopts a pulse jet oscillator channel, Its characteristics are: it contains one import and two exports. Under steady-state inlet conditions, that is, when the inlet flow rate does not change, the main flow flows out alternately at the two outlets, and at each outlet, a pulsed jet is formed along the direction of the outlet channel.

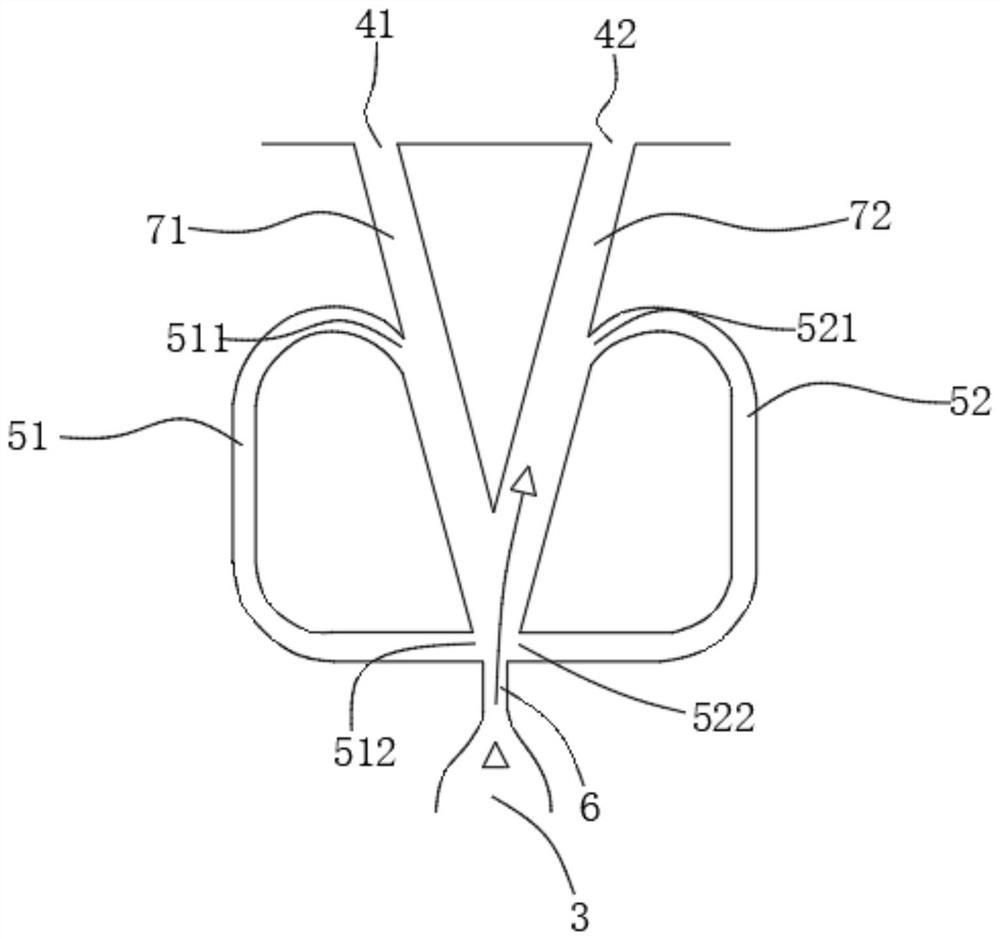

[0059] refer to figure 1 and figure 2 , the flow path 2 of the fluid oscillator in this embodiment includes: an oscillating jet bleed air inlet 3, an oscillating jet outlet 4, and a jet feedback for partly flowing from the oscillating jet bleed air inlet 3 to the oscillating jet outlet 4 The two feedback passages 5 return to the connecting portion between the oscillating jet bleed air inlet 3 and the oscillating jet outlet 4 .

[0060] r...

Embodiment 2

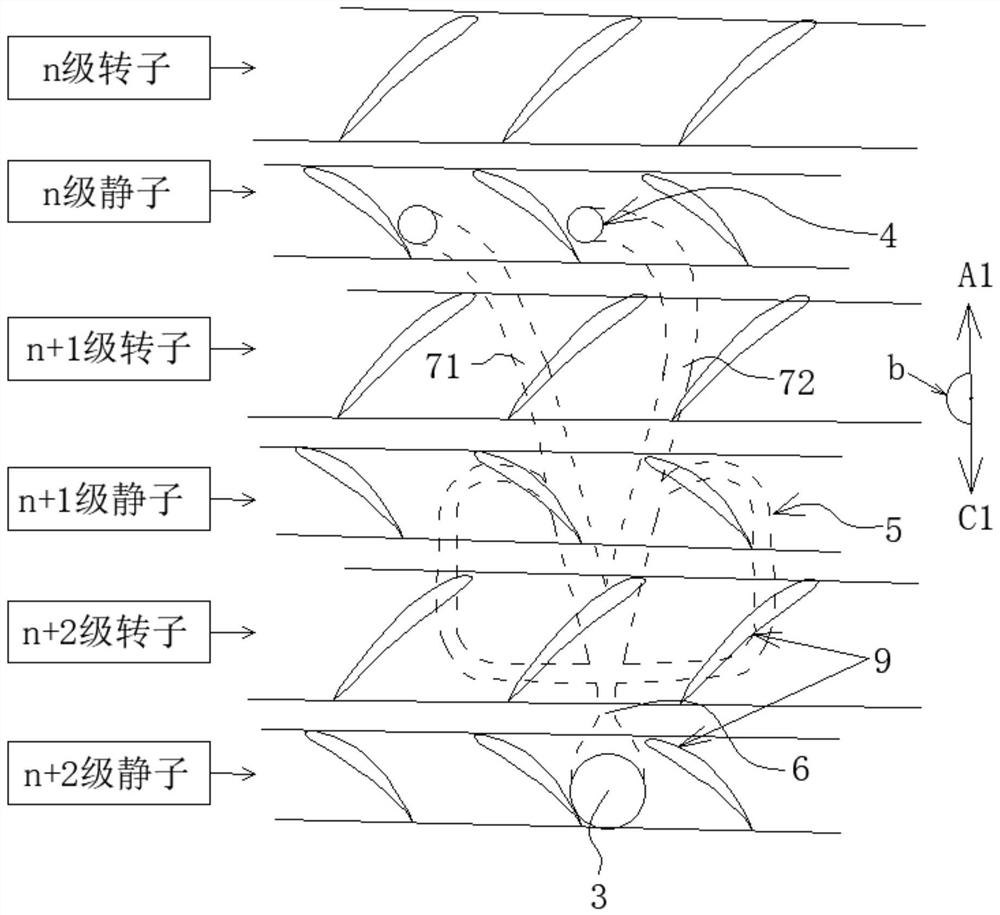

[0072] refer to Figure 7 , this embodiment is basically the same as Embodiment 1, the difference is that: the first oscillating jet outlet 41 and the second oscillating jet outlet 42 are respectively located on any two adjacent blades in the nth stage stator 81 of the compressor 9 The position in the flow channel, or the position within the axial projection range of any two adjacent rotor blades on the nth stage of the compressor on the casing. For example, refer to Figure 7 , the first oscillating jet outlet 41 is located at the top of any blade 9 of the nth stage stator 81 of the compressor, and the second oscillating jet outlet 42 is located at the top of any blade 9 of the nth stage rotor 82 of the compressor .

Embodiment 3

[0074] This embodiment is basically the same as Embodiment 1, and the fluid oscillator channel 2 adopts a pulse jet oscillator channel, refer to Figure 8 , the difference is that the outlet of the inlet air-introduction channel 6 of the fluid oscillator channel 2 communicates with a first feedback port 53 and a second feedback port 54; the first feedback port 53 passes through a The feedback channel 5 communicates with the second feedback port 54 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com