Heat conduction piece, bearing composite supporting cooling structure and vacuum pump

A technology of composite support and heat dissipation structure, which is applied in the direction of bearing components, shafts and bearings, bearing cooling, etc., and can solve problems such as poor heat dissipation effect, vibration of bearings and bearing end covers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

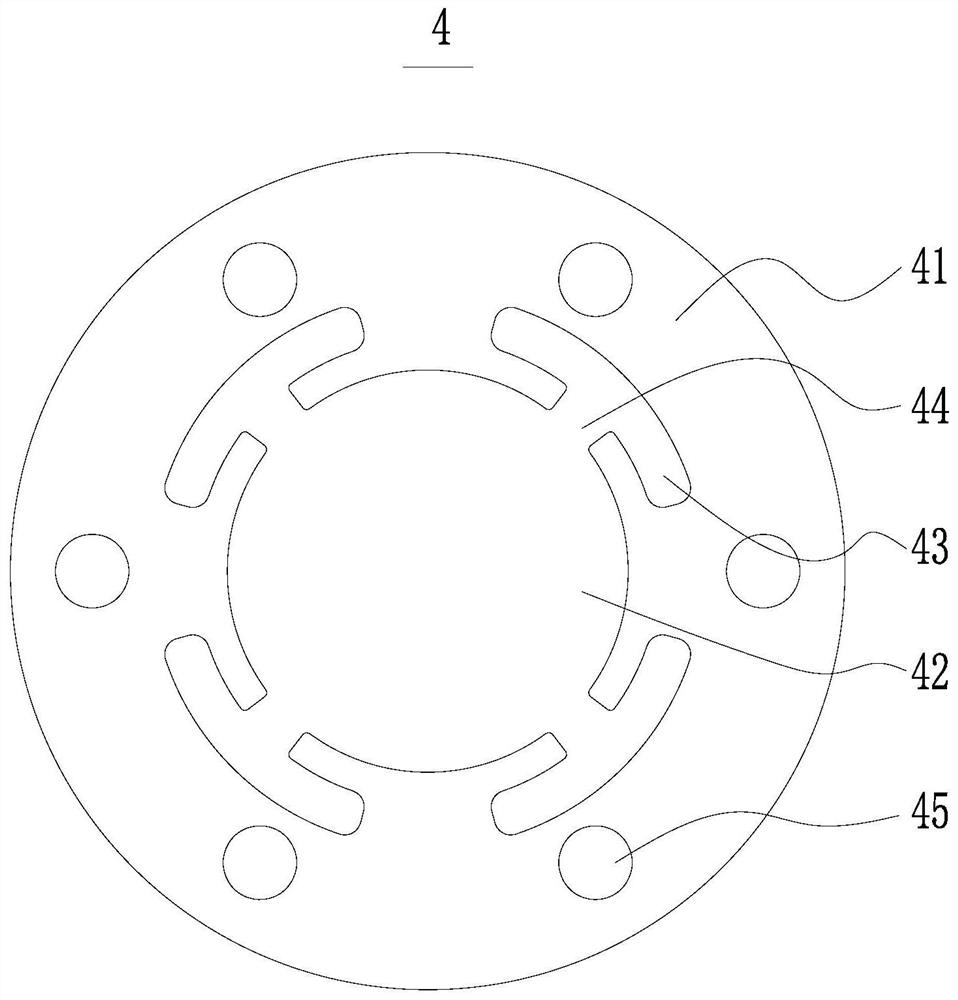

[0031] Please also refer to figure 1 and figure 2 , the heat conducting sheet 4 provided by the present invention will now be described. The heat conducting sheet 4 is used to be arranged between the bearing 1 and the bearing end cover 2 , and includes a body 41 , and the opposite sides of the body 41 abut against the bearing 1 and the bearing end cover 2 respectively.

[0032] Compared with the prior art, the heat conduction sheet 4 provided by the present invention is arranged between the bearing 1 and the bearing end cover 2 and sleeved on the rotating shaft 3. The heat conduction sheet 4 is opposite to the upper end surface of the bearing 1. Due to the bearing 1 The wall thickness of the upper and lower end surfaces is thinner or there is no sealed fixed wall, so the heat dissipation speed of the upper and lower end surfaces of the bearing 1 is faster. At this time, the heat conduction sheet 4 is covered on the upper end surface of the bearing 1 and can contact the condu...

Embodiment 2

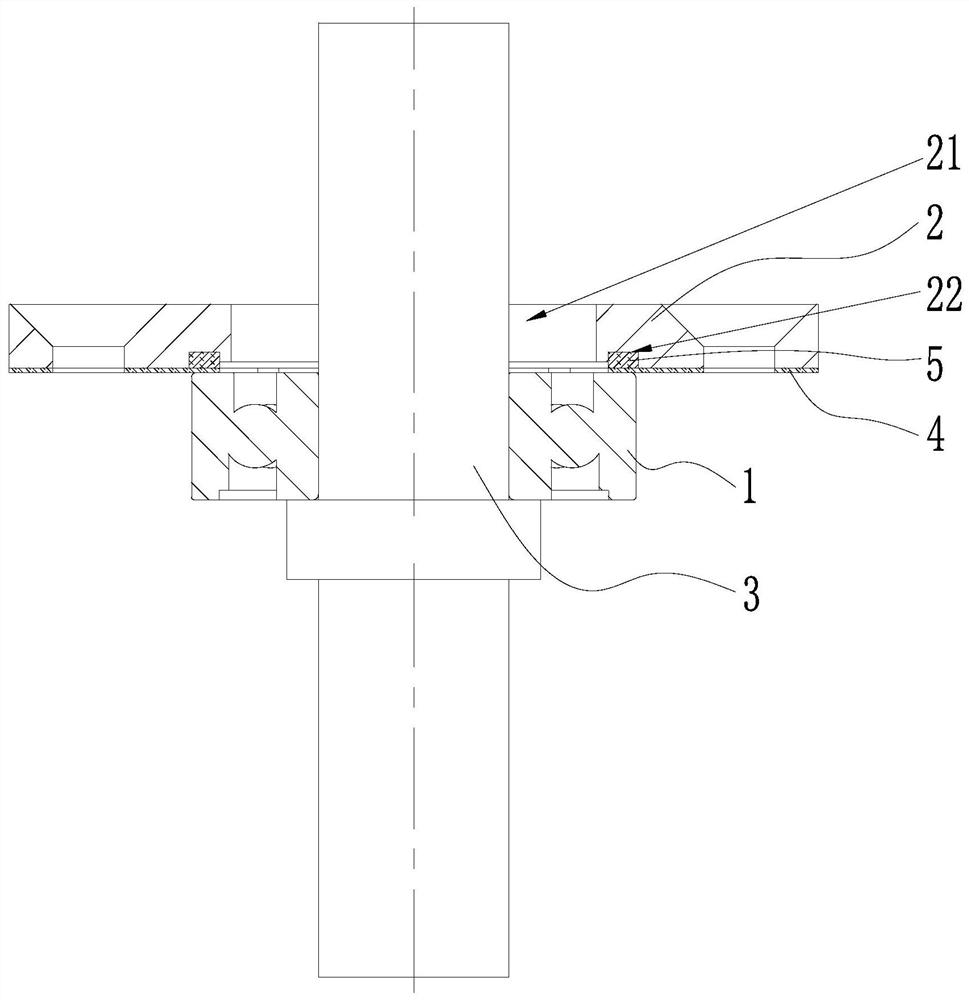

[0040] see figure 2 , the present invention also provides a bearing composite support heat dissipation structure, the bearing composite support heat dissipation structure includes a rotating shaft 3, a bearing 1 sleeved on the rotating shaft 3, a bearing end cover 2, a flexible washer 5 and as in Example 1 The heat conducting sheet 4, the rotating shaft 3 passes through the first through hole 42, the flexible gasket 5 and the heat conducting sheet 4 are both located between the bearing 1 and the bearing end cover 2, the One side of the flexible washer 5 is in contact with the bearing end cover 2 , and the other side is in contact with the heat conducting sheet 4 .

[0041] The bearing composite supporting heat dissipation structure provided by the present invention combines the flexible washer 5 with the heat conducting sheet 4, the flexible washer 5 can directly contact the heat conducting sheet 4 and the bearing end cover 2, and the flexible washer 5 and the bearing 1 pass ...

Embodiment 3

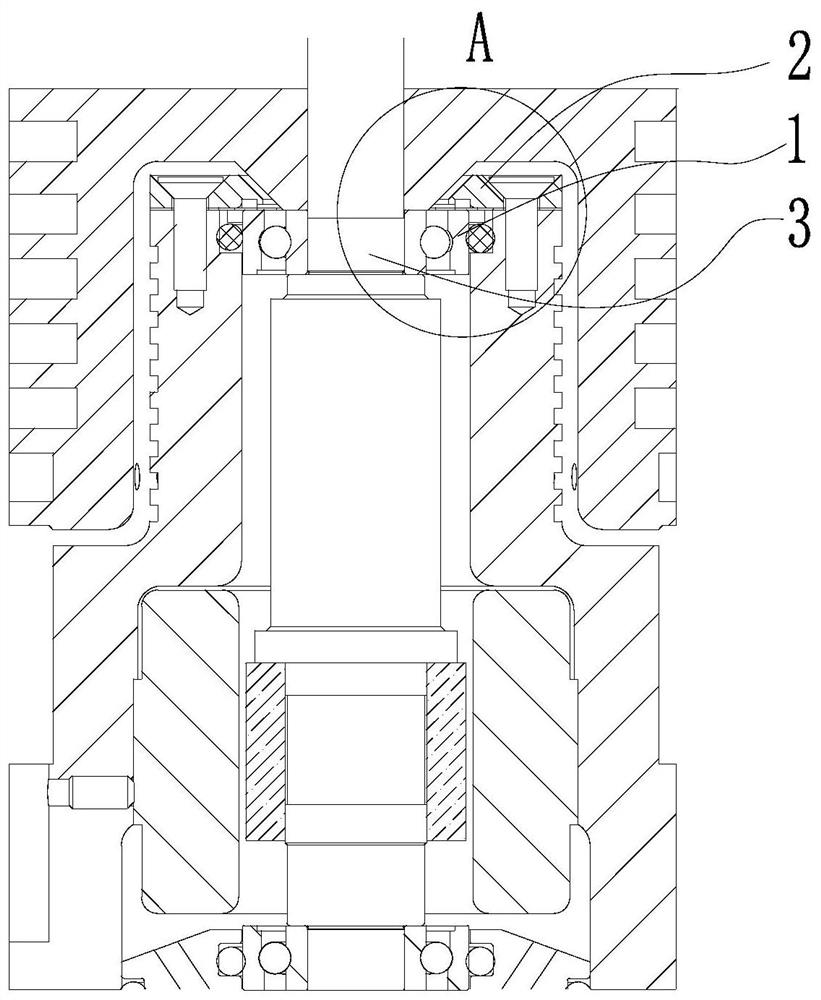

[0050] see image 3 and Figure 4 , the present invention also provides a vacuum pump, the vacuum pump includes the bearing composite supporting heat dissipation structure as described in Embodiment 2.

[0051] Compared with the prior art, the vacuum pump provided by the present invention adopts the composite supporting heat dissipation structure of the bearing in Embodiment 2, and utilizes the elastic energy of the flexible gasket 5 and the heat conducting sheet 4 to ease the tension between the bearing 1 and the bearing end cover 2 Vibration, the heat conduction sheet 4 can also realize contact heat dissipation at the same time, so that the bearing structure in the vacuum environment in the vacuum pump can still achieve a better heat dissipation effect, which can effectively prolong the service life of the bearing 1. The entire structure is compact and will not affect other parts of the vacuum pump. The installation and selection of components are highly replaceable, prolon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com