Ball valve with replaceable sealing ring

A sealing ring, ball valve technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as low efficiency in replacing sealing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

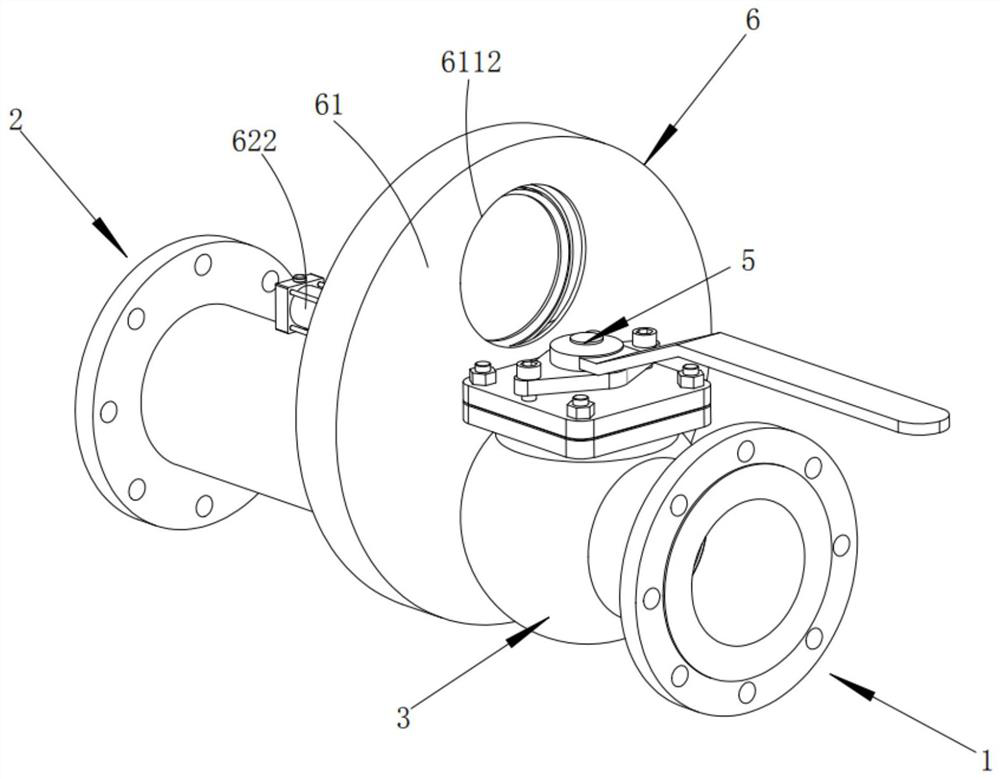

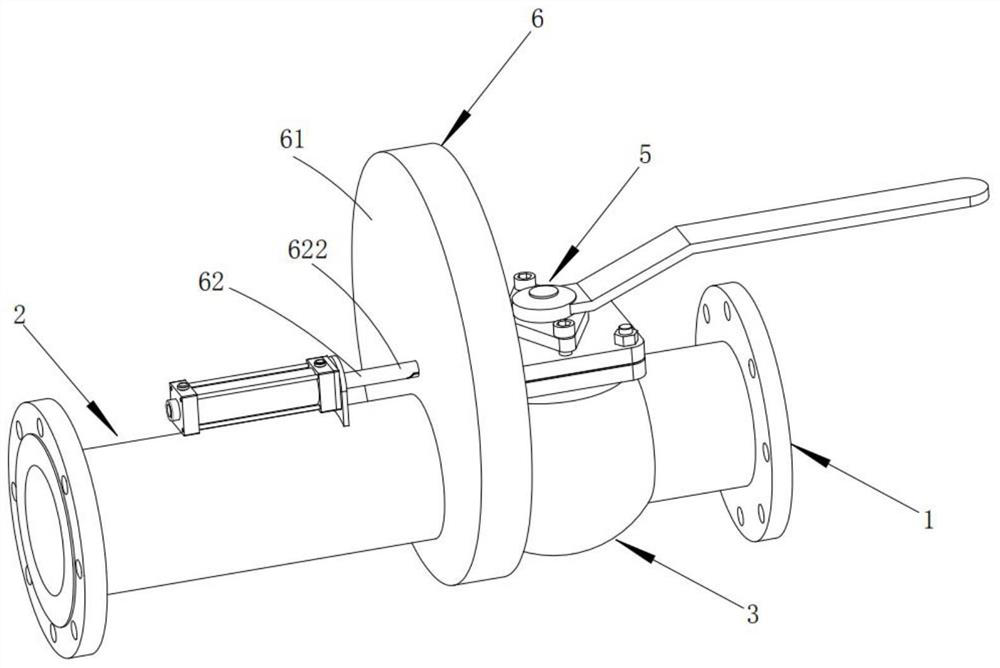

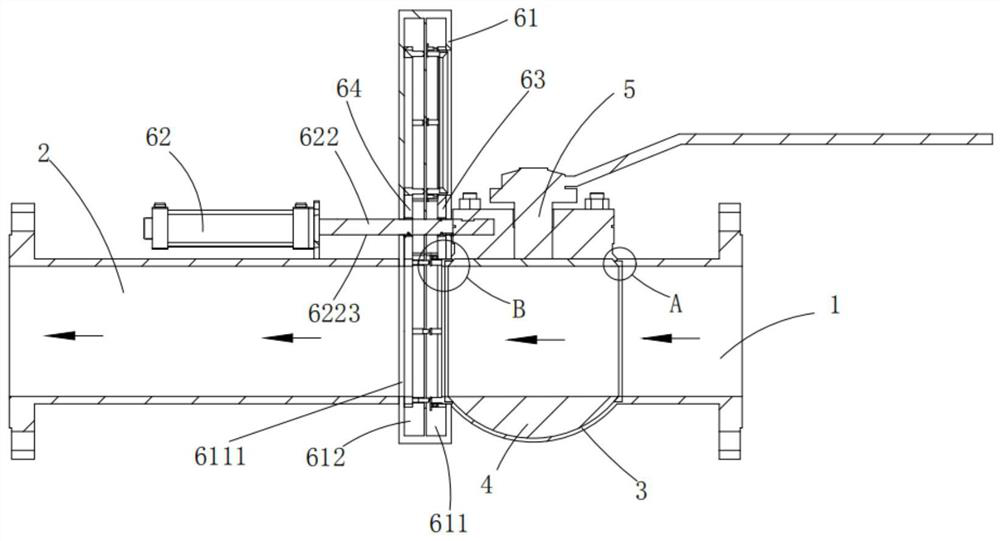

[0042] Such as Figure 1 to Figure 3 As shown, a ball valve with a replaceable sealing ring includes a water inlet pipe 1, an outlet pipe 2, a valve body 3, a valve core 4, a valve stem 5 and a sealing assembly 6, and the sealing assembly 6 includes:

[0043] A chamber 61, the chamber 61 includes a switch chamber 611 and a limit chamber 612 which are sequentially arranged between the outlet pipe 2 and the valve body 3 along the water flow direction and communicate with each other;

[0044] The driving assembly 62, the driving assembly 62 includes two sets of rotating mechanisms 621 respectively rotatably installed in the switching chamber 611 and the limiting chamber 612; Drive the power mechanism 622 that two groups of the rotating mechanism 621 alternately rotate;

[0045] Switching assembly 63, the switching assembly 63 includes two sealing seats 631 that are slid left and right on the rotating mechanism 621 in the switching chamber 611 and can be aligned with the outlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com